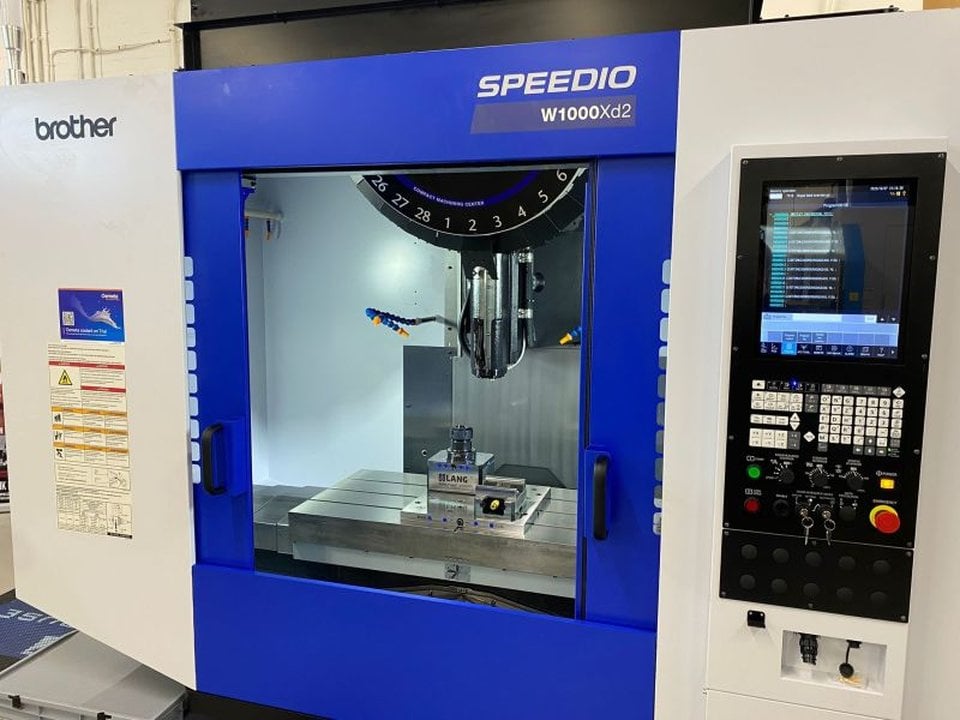

Unexpectedly available for demonstration at Southern Manufacturing 2019 is a Brother Feedio robotic component handling system. The compact unit will be shown linked to the Japanese manufacturer's Speedio M140X1 5-axis, 30-taper mill-turn centre on the stand of sole UK and Ireland agent, Whitehouse Machine Tools.

The plug-and-play automation system, which can be retrofitted to increase the production efficiency of any 3- to 5-axis machining centre in the Speedio range, communicates with the Brother control via a Profibus interface. It is supplied with an ABB 6-axis robot and the manufacturer’s smart teach pendant incorporating a customised Speedio page.

Extended periods of unattended and overnight running are possible, enabling manufacturers to make the most of their investment in the machining centre in the knowledge that the automation has been designed specifically for it and is not a generic solution provided by a third party.

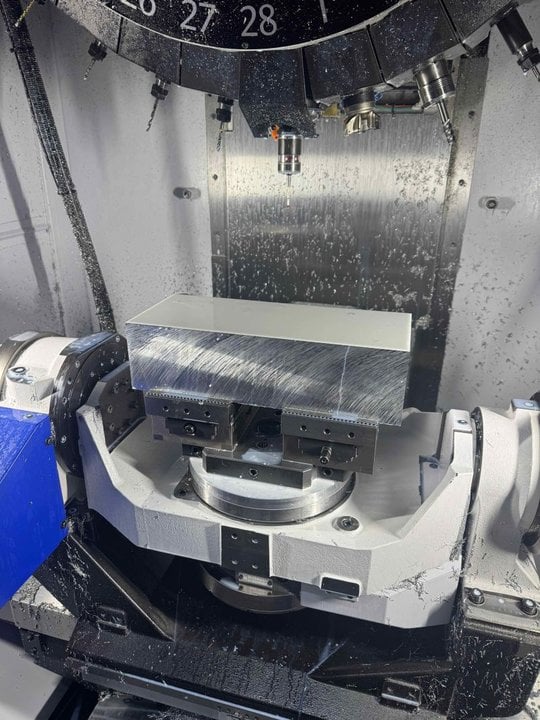

Having a handling capacity of 10 kg or 20 kg, the robot can be equipped with standard interchangeable grippers with two or three fingers or an adjustable double gripper, all with an air blow nozzle if required. A camera vision system and built-in PC allows the robot to detect where on the upper inlet conveyor a workpiece has been placed. After machining, components are returned to an output conveyor positioned below the first.

Accessibility to the machine from the front is maintained by positioning the automation unit to the side, a configuration that allows it to serve two Speedios. Options include a static station for regripping a component, a turn-around station, and equipment for deburring, washing, air cleaning and part marking.