- Newsna

Mazak Advances Support for Technical Education

Japanese machine tool manufacturer Mazak continues to strengthen its commitment to technical education by fostering hands-on learning opportunities in the manufacturing sector. In a significant move, Mazak has announced its support for students at Anoka Technical College. Mazak’s collaborati…

MTDCNCLast viewed

MTDCNCLast viewed - Newsna

Boeing’s Everett Factory: A Giant of Aerospace Production

Boeing’s Everett factory in Washington, USA, stands as a monumental achievement in manufacturing as the largest building by volume globally. Enclosing over 472 million cubic feet, this facility is a vital part of the Pacific Northwest’s aerospace industry. Established in 1967 primarily…

MTDCNCLast viewed

MTDCNCLast viewed - Newsna

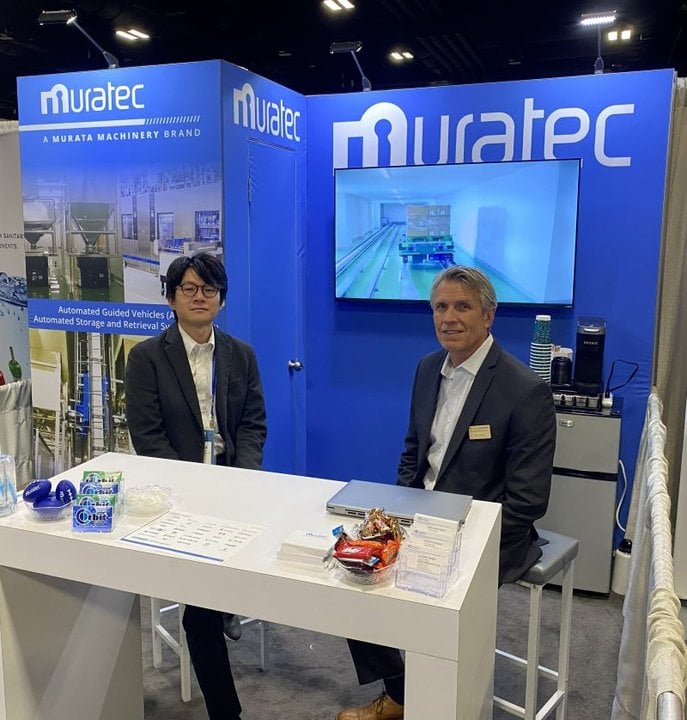

Muratec to Showcase Automation at MODEX 2026

Muratec is set to unveil its Integrated Model at the upcoming MODEX 2026 event, taking place from April 13 to 16 at the Georgia World Congress Center in Atlanta, USA. The company aims to highlight advancements in automation through its comprehensive solutions for shuttle sortation, material flow a…

MTDCNCLast viewed

MTDCNCLast viewed - Newsna

Sandvik Coromant introduces CoroTap 100 series for uninterrupted precision threading!

Sandvik Coromant has introduced the CoroTap 100 series with -PM geometry, a range of straight-flute cut taps designed to deliver reliable and uninterrupted threading performance in ISO P materials. The new taps incorporate a high-performance chipbreaking design that helps reduce production interru…

MTDCNCLast viewed

MTDCNCLast viewed

NA

Popular North America

Boeing’s Everett Factory: A Giant of Aerospace Production

Boeing’s Everett factory in Washington, USA, stands as a monumental achievement in manufacturing as the largest building by volume globally. Enclosing over 472 million cubic feet, this facility is a vital part of the Pacific Northwest’s aerospace industry. Established in 1967 primarily for the production of the Boeing 747, the factory has since expanded its output to include the 767, 777, 777X, and parts of the 787 Dreamliner. It notably supports a workforce of over 30,000 in its main assembly structure, sprawling across 98.3 acres within a vast 1,000-acre complex adjacent to Seattle Paine Field International Airport. The Everett site

MTDCNCLast viewed

MTDCNCLast viewed

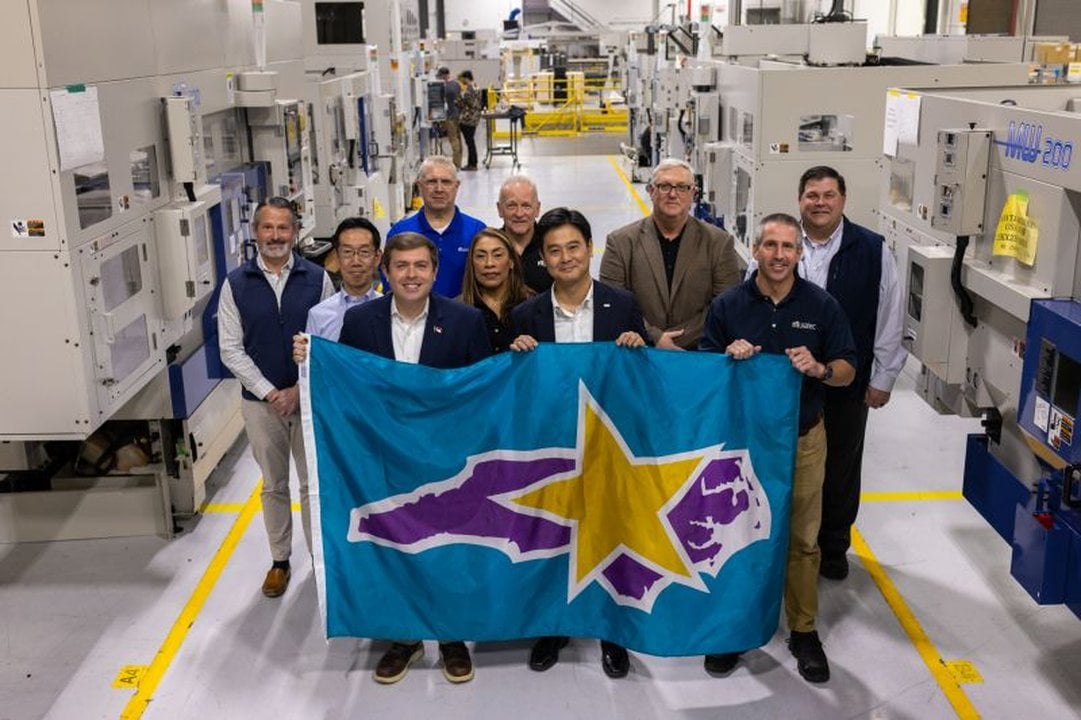

Mazak Advances Support for Technical Education

Japanese machine tool manufacturer Mazak continues to strengthen its commitment to technical education by fostering hands-on learning opportunities in the manufacturing sector. In a significant move, Mazak has announced its support for students at Anoka Technical College. Mazak’s collaboration with educational institutions aims to equip the next generation of manufacturing professionals with the essential skills for the industry. The company’s partnership with Crown Extrusions Inc., noted for its focus on aluminium products, further exemplifies its dedication to creating a practical learning environment. The presence of Mazak’s advanced machinery at Anoka Technical College provides students with the opportunity to engage with

MTDCNCLast viewed

MTDCNCLast viewed

Automation Trends Transform Fabrication Industry

The Fabricators and Manufacturers Association has recently highlighted evolving automation trends within the fabrication industry. Reports suggest a growing focus on integrating automation beyond individual processes, such as in cutting and lights-out production, to drive greater impact across operations. The insights emerged from the association’s fourth quarter Job Shop Consumption Report, which points to a broadening scope of automation application among fabricators. Automation is no longer confined to enhancing reliability and consistency within isolated tasks. Many in the industry now consider broader integration opportunities to maximise efficiency and productivity. These developments underscore the industry’s recognition of automation as a crucial

MTDCNCLast viewed

MTDCNCLast viewed

Multi-Pallet Machining: Key to Boosting Job Shop Efficiency

Multi-pallet machining is emerging as a critical strategy for job shops aiming to enhance spindle utilisation and efficiency. Traditional three-axis vertical machining centres (VMCs) typically achieve about 30% spindle utilisation, whereas multi-pallet systems can exceed 80%, offering significant productivity improvements. Job shops often specialise in high mix, low volume parts, which present challenges when using equipment that demands multiple complex setups. Parts produced on a three-axis VMC from a solid billet require extensive setup time and batch production to remain competitive. In contrast, multi-pallet machines streamline this process, allowing for efficient and flexible operations. Additionally, downtime during part inspections with

MTDCNCLast viewed

MTDCNCLast viewed

Kennametal Unveils Road King Diamond™ 303R at CONEXPO-CON/AGG 2026

Kennametal has launched its latest innovation, the Road King Diamond™ 303R, at the CONEXPO-CON/AGG 2026 event. This polycrystalline diamond (PCD) road milling pick promises to significantly reduce downtime while enhancing performance in the field. The Road King Diamond™ 303R has been engineered for durability and reliability, ensuring a consistent cutting pattern and depth throughout its operational life. This non-rotating, rugged pick, developed by Kennametal’s team of wear protection experts, represents a breakthrough in the technology used for road milling applications. Visitors to the CONEXPO-CON/AGG 2026 can witness the new Road King Diamond™ 303R firsthand. Kennametal’s team will be present at

MTDCNCLast viewed

MTDCNCLast viewed

CentroteX Reduces Downtime, Boosts Productivity

Extended machine downtime significantly impacts manufacturing productivity, leading to missed delivery deadlines, decreased customer satisfaction, and lost revenue. A solution to this pervasive issue is centroteX, a tool designed to minimise downtime and maximise operational efficiency. CentroteX offers several key benefits for manufacturing operations. It boasts short lead times in production, ensuring that manufacturers can quickly adapt and continue their processes without lengthy delays. The integration process for centroteX is straightforward, allowing it to seamlessly fit into existing equipment setups without the need for extensive modifications or additional resources. Reliability is at the core of centroteX, promising consistent performance that

MTDCNCLast viewed

MTDCNCLast viewed What MTDCNC can do for you

Your partner for marketing, media, and events in manufacturing.

Upcoming Events USA

See what’s coming up and join us on the road.

6–7 May 2026

6 – 7 May | Greater Chicago Design 2 Part Show | Schaumburg

The Design-2-Part Trade Show is the ideal marketing opportunity for contract manufacturers and job shops in the metal, plastics, rubber, electronics, and finishing industries. How We Promote We use several different methods of direct marketing that target qualified OEM engineers and buyers looking for manufacturing services. This includes:

20–21 May 2026

20 – 21 May | Greater Denver Design-2-Part Show

The Design-2-Part Trade Show is the ideal marketing opportunity for contract manufacturers and job shops in the metal, plastics, rubber, electronics, and finishing industries. How We Promote We use several different methods of direct marketing that target qualified OEM engineers and buyers looking for manufacturing services. This includes:

14–18 September 2026

14 – 19 September | IMTS | Chicago

The Largest Manufacturing Show in the Western Hemisphere As the largest trade show in the Western Hemisphere, IMTS – The International Manufacturing Technology Show draws the innovators, sellers, and drivers of manufacturing technology together to connect, be inspired, and find new solutions. Looking for more information on all things IMTS 2026? You’ve come to the right place. Are you exhibiting at this event, and want MTDCNC’s support? Fill in the form and one of our team will be in touch to see how we can help you make the most of exhibition!

Podcast

Here at MTDCNC, you’ll find a collection of top-notch podcasts featuring discussions and insights from the manufacturing market.

What makes this year’s Student Summit unmissable?

It’s a launchpad for thousands of students discovering high-tech, high-impact, and highly lucrative careers. In this powerful episode of the MTDCNC Podcast, Catherine Ross joins Arthur Field to explain why the IMTS 2026 Student Summit isn’t just another event. From 15,000+ students engaging hands-on with robotics and automation to real job pathways, internships, and career connections, this is where inspiration turns into opportunity. If the industry is serious about closing the skills gap, this is where the action starts. As Catherine puts it, “Careers in manufacturing can disrupt generations of financial struggles…” The question is – will we show up

Star-SU: 100 years of people, precision and motion

“They don’t just sell tools. They help the world turn, literally.” Behind every precision gear is a human story worth hearing. This is the real story behind nearly a century of family-led manufacturing at Star-SU, shared by Jeffrey Lawton on the latest MTDCNC Podcast. From generational leadership and global growth to resilience, risk-taking, and people-first values, this conversation explores what it truly takes to last in manufacturing: a powerful reminder that progress comes from craftsmanship, relationships, and never losing sight of the human side of industry.

How fast can your machine builder get you running again?

You know you’ve got the right partner when uptime is built into their entire service philosophy! That’s what Starrag is all about. In today’s podcast, MTDCNC’s Arthur Field talks with Rob and Steven of Starrag about how their team classifies parts, manages everything through their ERP system, and ships critical replacements straight from their Kentucky warehouse. From a flooded vertical turning center to modernizing a 1970s machine to 2025 standards, their service stories are proof that Starrag keeps customers’ machines running. Tune in to learn how smart stocking, global technician coordination, and precise ticket tracking help Starrag react fast when

What’s the difference between a supplier and a partner?

They don’t just sell a machine and drop it on your shop floor — Starrag runs the entire journey as a full project. In this MTDCNC podcast, Arthur Field sits down with Udo and John of Starrag to unpack how the company delivers almost 24/7 cross-continental project management, structured kick-off meetings, and deep technical support. With around 70% of their North American business in defence and ITAR and over 70 machines supporting programs like the F-35, Starrag brings the engineering strength to handle everything from tooling and turnkey programming to massive foundations. Tune in to learn how Starrag becomes a

They’re bringing BIG updates to the North American market!

From compact series machines and powerful five-axis platforms to the revolutionary Matrix Tool Magazine holding up to 828 tools, Starrag is delivering complete solutions for the shop floor. MTDCNC’s Arthur Field sits down with Udo Herbes and Jim Stolo at Starrag’s Kentucky HQ to unpack everything new for the North American market: RCS CAM software, more hands-on factory training for service techs, expanded support across North America and Mexico, and more. If you’ve ever wondered what it takes to keep high-end manufacturing ahead of the curve, this MTDCNC podcast with Starrag is one you can’t miss! Interested in hearing some

The Best Investment You’ve Never Heard Of: Why MEP Is Saving U.S. Manufacturing!

Quietly operating in the background of American manufacturing is one of the nation’s most effective programs, NIST’s Manufacturing Extension Partnership (MEP). Designed as a public–private network, MEP helps small and medium-sized manufacturers modernize operations, embrace technology, and compete in a global economy that’s changing faster than ever. While large corporations often have access to consultants, engineers, and global supply chains, smaller manufacturers typically work with tighter budgets, limited expertise, and far less time. That’s where MEP steps in. With a nationwide network of nearly 1,400 experts and thousands of affiliated organizations, the program connects manufacturers of every size and specialty