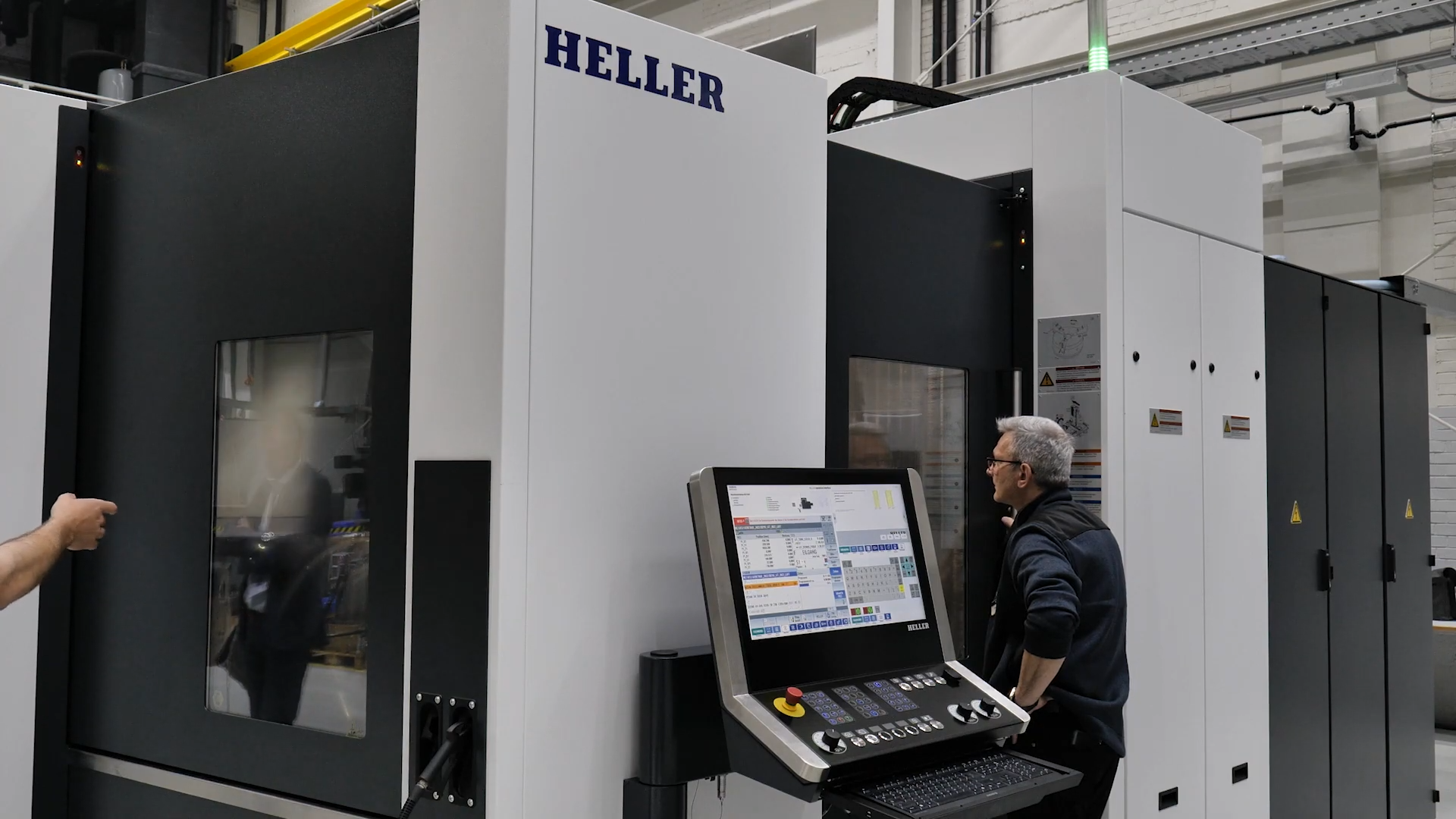

An advanced training machine designed to raise the skill level of horizontal machining centre operators away from the shop floor has been introduced by Heller Machine Tools. Available for demonstration in the new customer area at the company's Redditch factory, the latest CNC ProfiTrainer builds on the capabilities of an existing 4-axis version with rotary table by offering the option of an additional +30 / -120 degree A-axis.

The fully configured, functional machine, which is powered by a single-phase electrical supply, is likely to be of interest to industrial training establishments, colleges and schools, especially as it is small enough to be transported between different educational centres if necessary. Larger OEMs and subcontractors may also choose to adopt the machine for operator training. There is a rental option, with payments subtracted from the purchase price if a customer later opts to buy the machine.

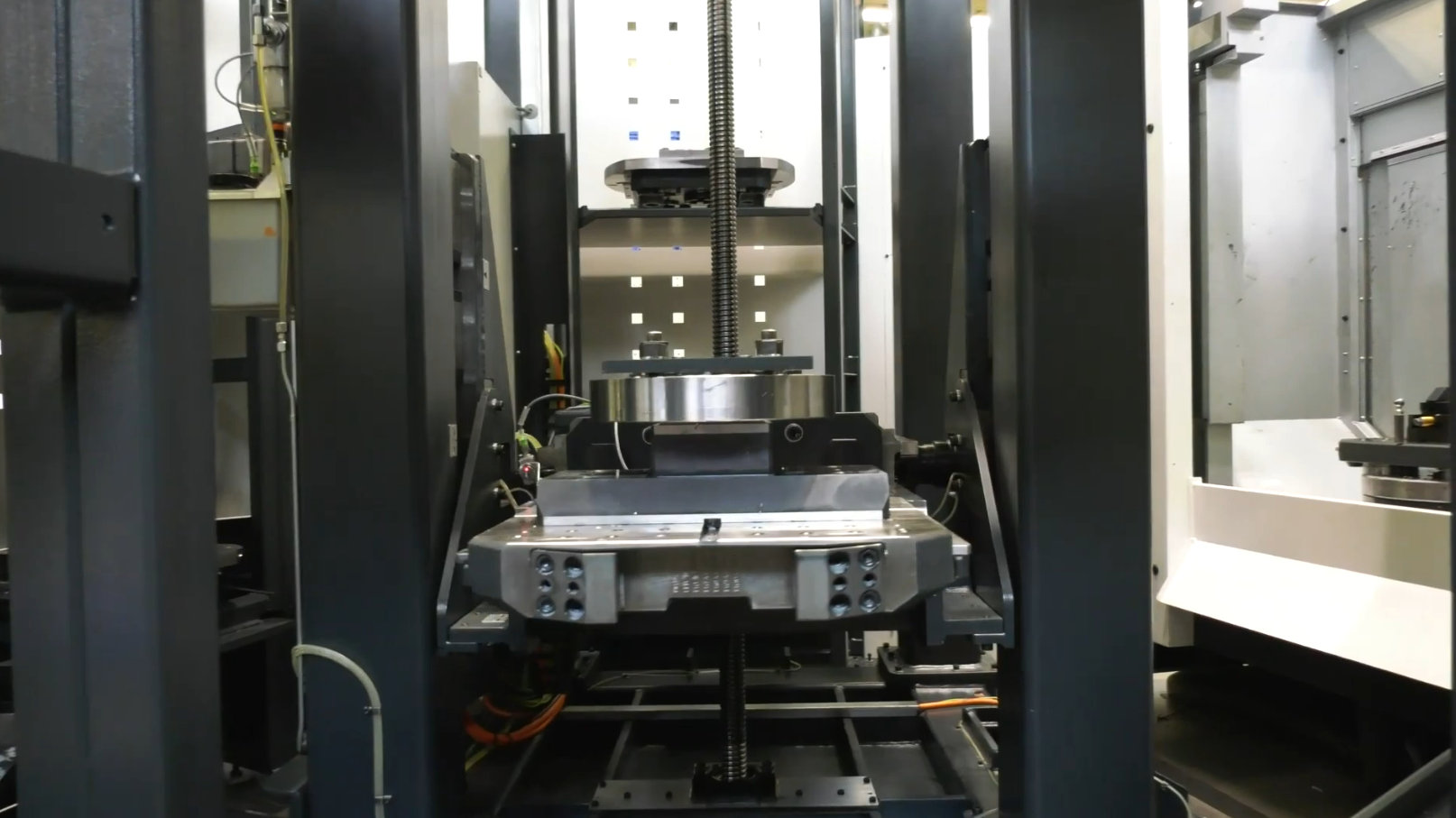

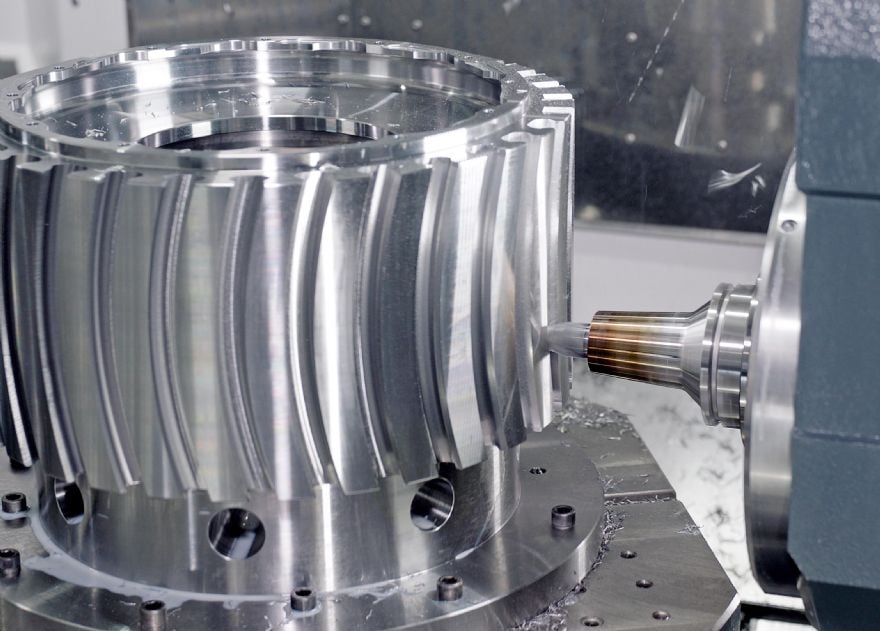

The realistic simulator is fitted with a full version of the Siemens 840D sl control and is now also available with Fanuc and Heidenhain equivalents. Having 200 mm linear travels driven by servomotors at up to 15 m/min over linear rails, the machine is designed to mimic realistically the operation of a full-size Heller machine tool. However, it can also be used to provide training for any make of prismatic machining equipment in a safe environment.

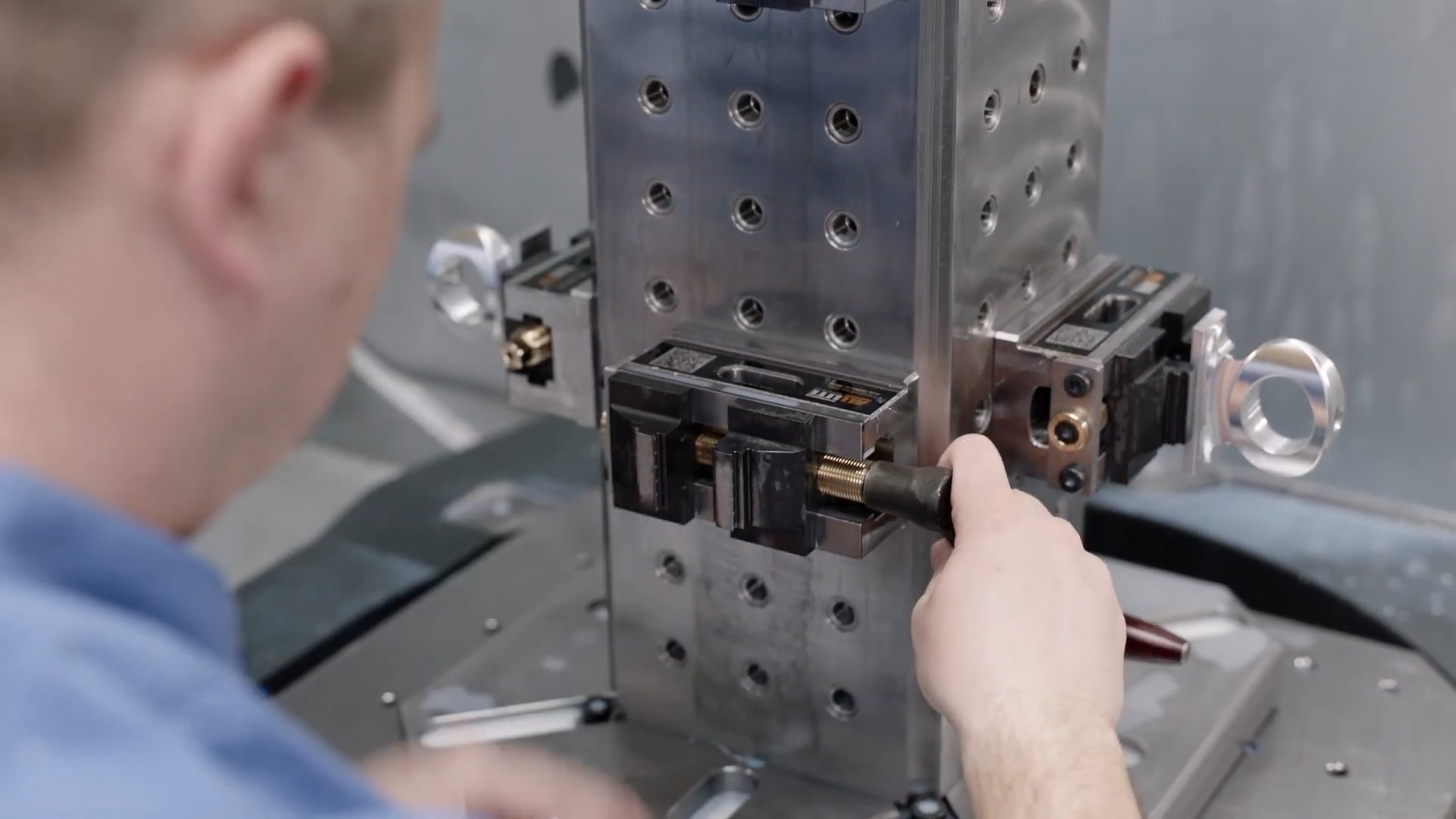

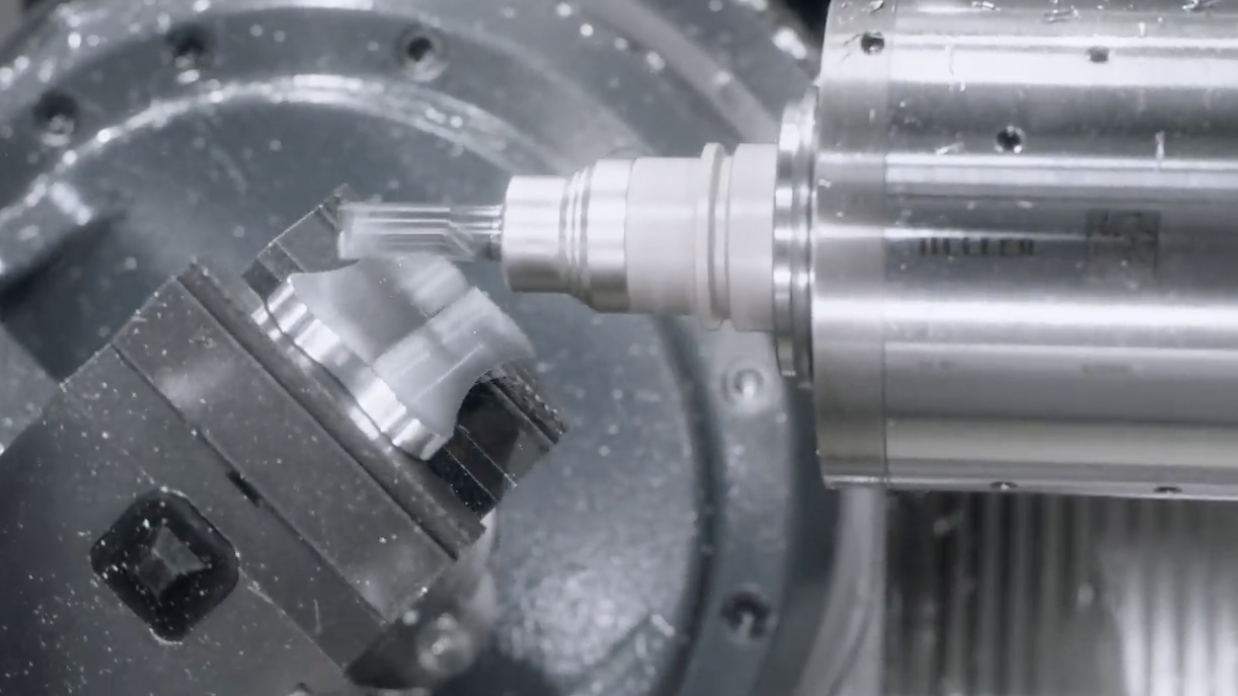

The multifunctional spindle is new. Driven by a 9,000 rpm / 2.75 Nm motor, it offers the options of an ER16 collet as well as manual and automated inserts for holding HSK25 tools. Even functions that cannot be performed on the training machine, such as operation of a tool magazine, can be simulated using control runtimes.

The facility, which is designed to tolerate operating errors, provides skills training without tying up a machine on the shop floor, which would result in lost production. Furthermore, the risk of a crash occurring on a real machine is eliminated, avoiding potential repair costs. Another benefit of the training unit is that its small size encourages trainees to try out new things.

Profitrainer is equally useful for mechanical and electrical maintenance courses, as the use of original components supports realistic handling of fault situations. Feedback from thousands of students who have used previous iterations of this unit over the past decade confirms the success of the concept.

Heller is a machine tool company renowned for its commitment to education. At any one time, apprentices account for 10 per cent of its global workforce, a figure mirrored at the UK factory in Redditch. The company is keen to transfer this ethos to the outside world and ensure that students and shop floor staff are also trained to a high standard.