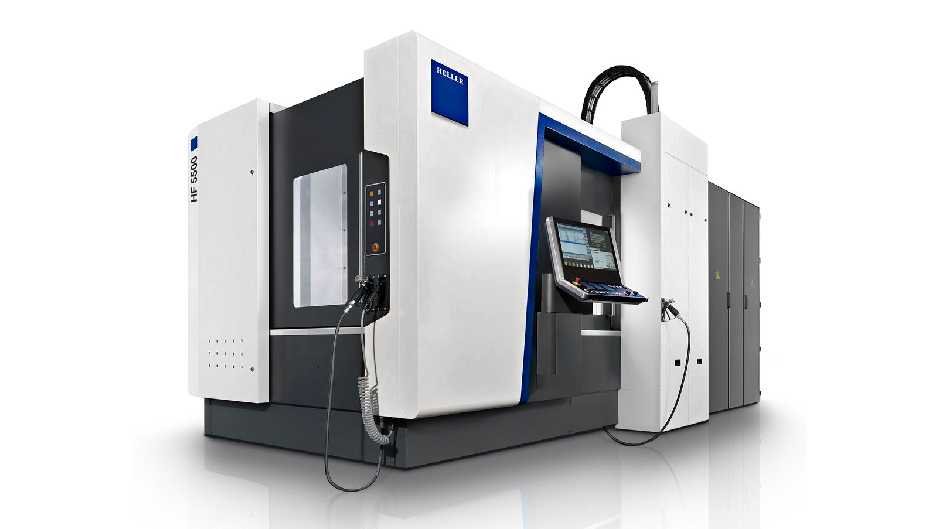

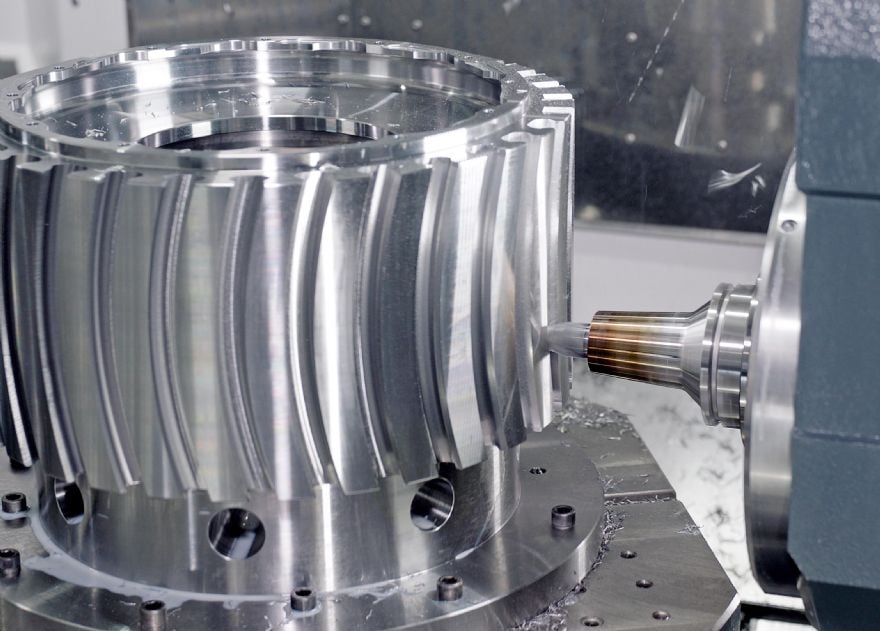

A new, horizontal-spindle machining centre for 5-sided and simultaneous 5-axis machining, the HF 5500, will be launched by Heller at EMO 2017 alongside the smaller HF 3500, which was introduced last year. With a 900 x 950 x 900 mm work envelope and a maximum pallet load of 750 kg, the larger machine offers approximately 200 mm extra travel in X, Y and Z plus 200 kg additional load capacity.

HF series machines are intended for highly productive, medium and large volume production in the automotive industry and its supply chain, as well as in the machine building industry. Optionally, productivity can be boosted with a ‘Speed-Dynamics Package’, which shortens chip-to-chip times by 10 per cent, and a high-speed lift-and-swivel tool changer that reduces idle times further.

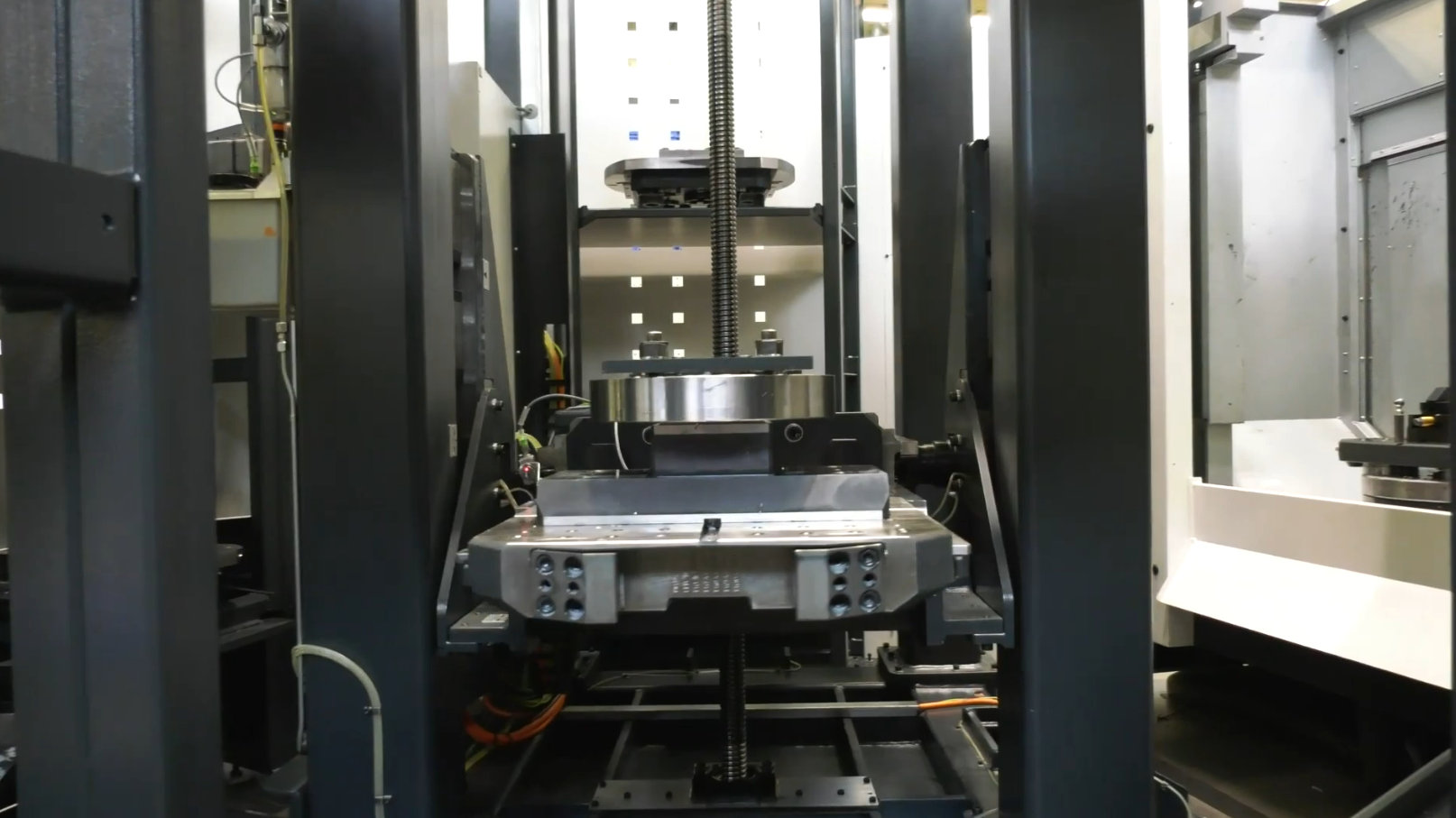

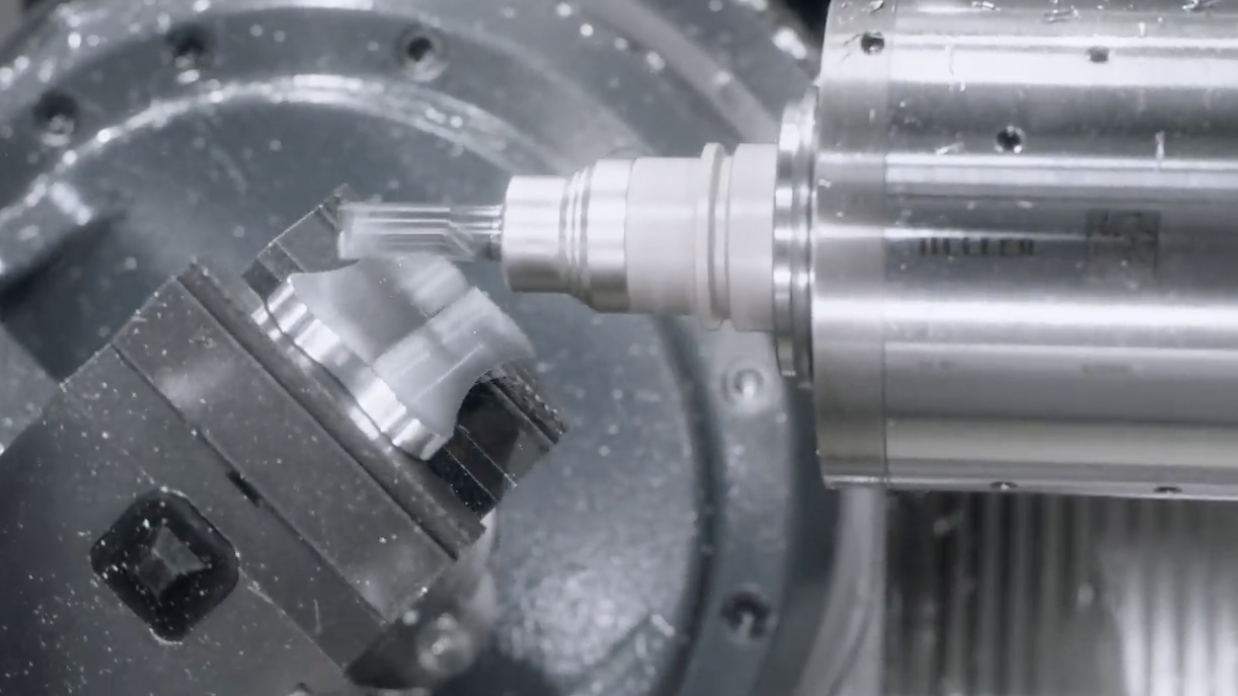

The machines have direct-drive rotary A and B axes integrated into a swivelling rotary table that has a low moment of inertia, allowing highly dynamic movements. The counter bearing supporting the AB axis is a unique selling point, according to the manufacturer, as in combination with the YRT bearings it helps to achieve extreme rigidity under high loads.

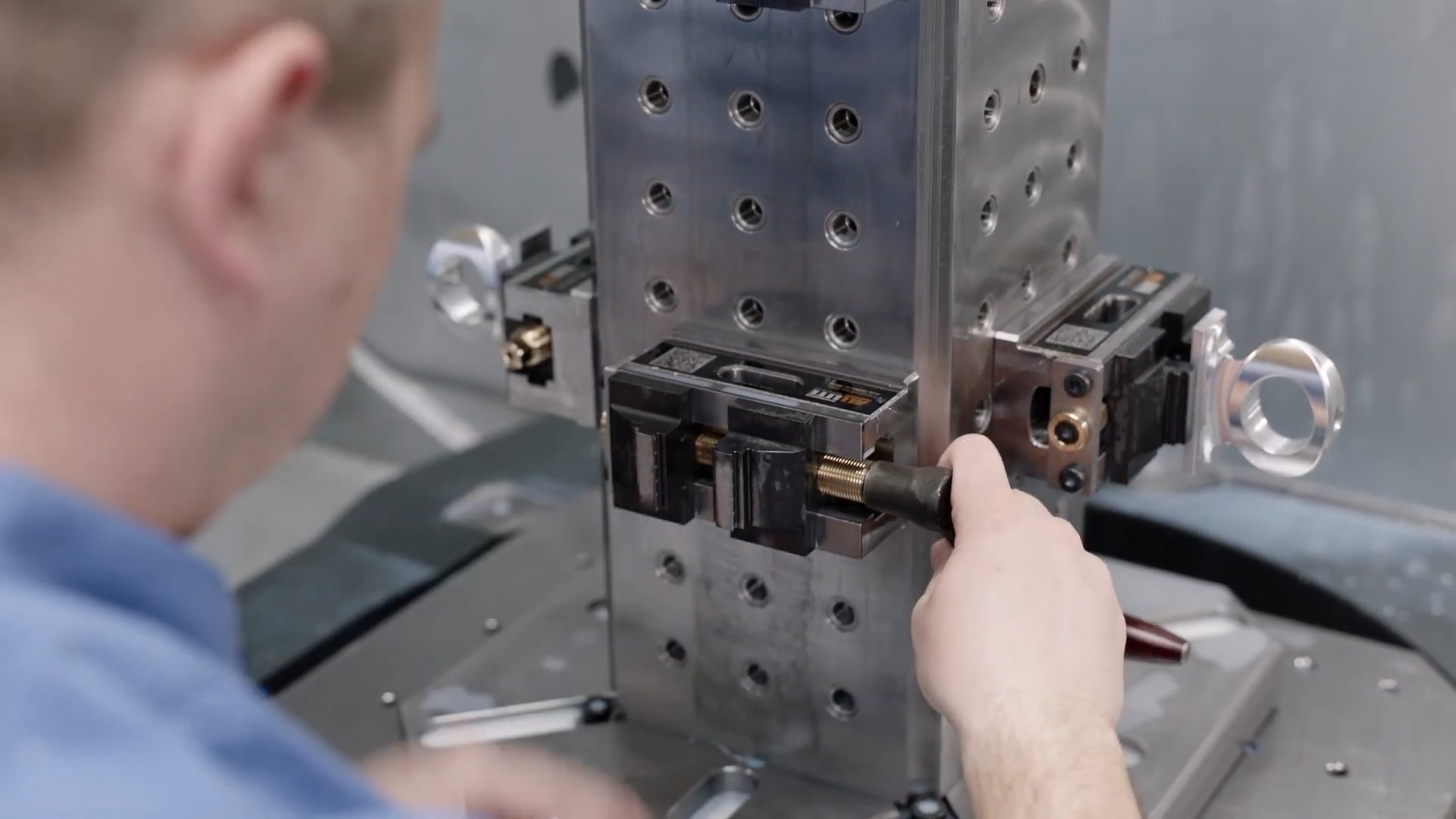

Large component sizes can be accommodated due to the generous interference contour, while still maintaining a +30 to -120 degree table swivel. With certain restrictions, the swivel range can be increased to 225 degrees. Whereas conventional 5-axis machining centres are generally configured for single-part clamping, Heller's HF series allows multiple part workholding or one very large component such as a transmission case to be secured.

Flexibility of use was another priority during the development phase, which is why the HF series is available with a choice of four different in-house manufactured spindles, with either an HSK-A63 or HSK-A100 taper, offering speeds up to 18,000 rpm and torques to 452 Nm. Versions of the machine are available for table loading or with a twin pallet changer.

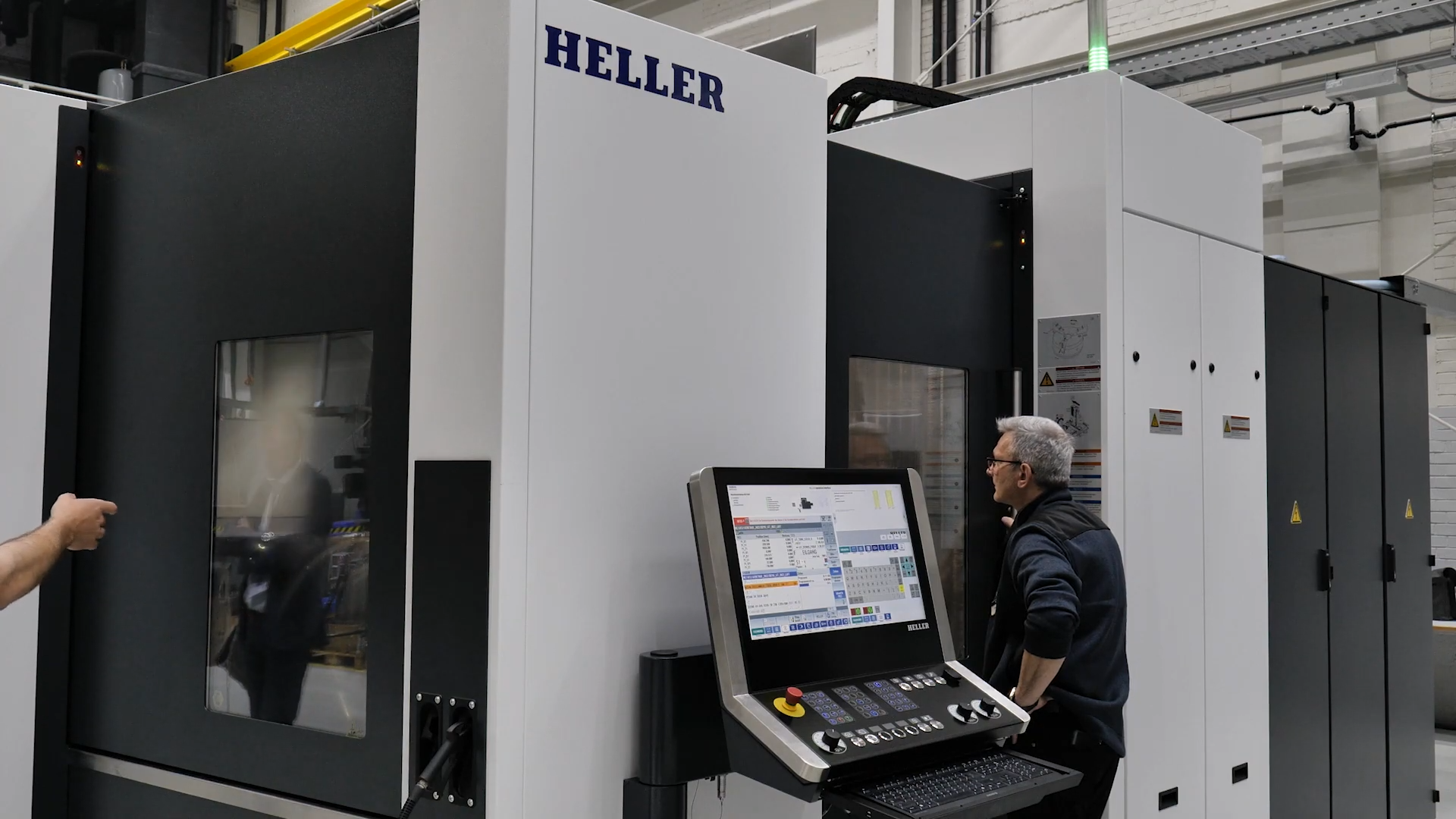

The free chip fall of the horizontal-spindle design is augmented by steep side walls and a centrally positioned chip conveyor, covers being of stainless steel. The new Heller Operation Interface has a 24-inch touchscreen and offers quick access technology in the control, while an optional camera in the work area supports setting and monitoring. Connectivity to Heller automation systems and flexible integration into existing production lines are possible.

Heller’s Industry 4.0 initiative

Increasing productivity through consistent Industry 4.0 practices, which the company calls HELLER4Industry, will be another theme of the stand at EMO. Core aspects are supplementary machine functions, on-demand services and enhanced maintenance. The importance of ease of operation, customised workpiece manufacturing and enhanced evaluation of existing data will be stressed.

HELLER4Operation is an easy-to-use, operator-oriented user interface for the company’s machines. The use of touchscreen controls at the tool/workpiece loading station promotes rapid and easy operation, facilitates the manufacture of individualised products and helps to integrate production into the value chain.

The HELLER4Services interface focuses on transparency of digital manufacturing and maintenance processes. The module forms the basis for evaluation of machine data and statistics, supporting a reduction in downtimes. Additionally, the visualisation of specific information such as status displays of axes and spindles enables users to predict wear and implement preventative maintenance to avoid unscheduled downtimes.

Lastly, HELLER4Performance includes the workpiece-specific optimisation of the machine. It comprises analysis for process and performance optimisation, extraction of real-time data over the internet, and evaluation and graphical display in the cloud.

In practice, it could for example map tool paths and workpiece tolerances in parts of a cycle where tool wear is expected. That section of the sequence would be run on the machine without cutting metal so the paths actually traversed by the tool could be recorded and compared with the workpiece design. The ability of the machine to actually produce the part to the required accuracy could then be ascertained.

The overall aim of these HELLER4Industry measures are reductions in a customers’ cycle times and hence in the cost of workpiece manufacture. Even today, Heller is generating added value by promoting greater ease of use of its customers’ machines, their optimal integration into a network and expanded functionalities and services.

Additional projects

Other developments to be announced at EMO include a focus on lightweight materials. The demand for reductions in vehicle weight inevitably requires the use of light metals and carbon fibre-based plastics. In this context, Heller is researching the most appropriate machining processes.

Another project is metal additive manufacturing. The company’s engineers are developing a cost-effective process providing high material deposition rates in an industrial environment to add features to a component, followed by subtractive machining. The goal is to find solutions for series production applications in the automotive and general machine building industries.

Heller already implements additive technology through its cylinder bore coating (CBC) technology, as visitors to EMO will learn. Intended for use in high-volume production of internal combustion engines, the coating halves frictional forces between cylinder and piston ring. Elimination of cast liners enables a more compact crankcase design and significantly reduced cylinder bore spacing, resulting in a smaller engine and hence weight savings.

All cylinder surfaces of current passenger car and truck engines with bore diameters from 70 mm to 150 mm can be coated using the CBC process. Major vehicle manufacturers have already equipped their production facilities around the world with the technology and are producing high volumes or are planning to do so at more than 20 locations. At the end of 2016, 32 CBC machining systems had been delivered and that number will have doubled by 2018.