🎧Hexagon enhances hip prosthesis production

Dedienne Santé, a French medical device manufacturer specialising in hip prostheses, has significantly improved its quality control process by implementing three advanced Hexagon CMMs. These technologies have enhanced measurement accuracy and reduced inspection times by 20%, setting new standards in medical device manufacturing.

Founded in 1986 and based in Mauguio, France, Dedienne Santé is a leading SME specialising in surgical products, particularly dual-mobility hip replacements. As a manufacturer of high-precision prostheses, the company must adhere to strict industry standards, where any deviation can lead to serious consequences. Ensuring complete conformity at every stage of production is essential.

Improving quality control

with precision technology

To enhance the quality control process for its hip prostheses, Dedienne Santé aimed to automate the dimensional measurement of critical components such as the cup (half-sphere part), liner, femoral head and stem. These parts must be measured precisely during production and final inspection to ensure conformity with strict medical standards.

Previously, these measurements were conducted manually, which required significant time and effort. Dedienne Santé collaborated with Hexagon to address this challenge and provide reliable, accurate, and swift measurement solutions.

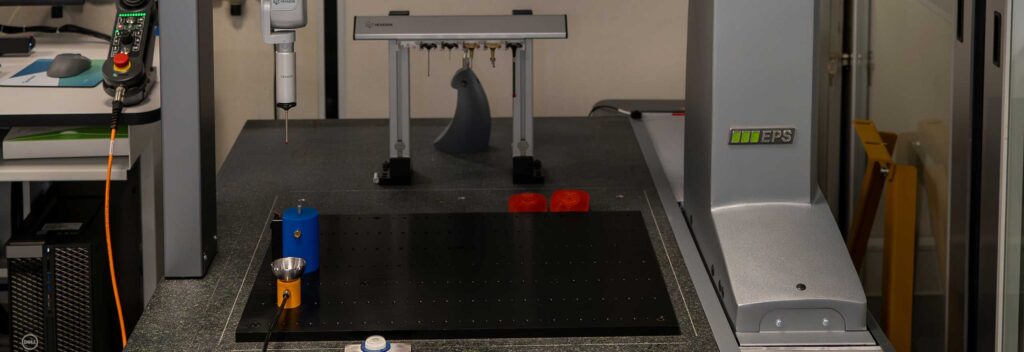

To meet Dedienne Santé’s needs, Hexagon deployed one GLOBAL Scan+ CMM and two retrofitted CMMs. These machines are equipped with highly accurate HP-S-X1 scanning probes and rotating probe heads, which are ideal for measuring roundness and sphericity. The systems also feature PC-DMIS metrology software that simplifies the measurement process, along with an Eco Mode that automatically shuts down the system when not in use, promoting energy savings.

The user-friendly software, combined with automated and visual execution methods, enables operators to assess part conformity with just a few clicks. “We chose Hexagon CMMs for their ability to measure dimensions and circularities down to a hundredth of a millimetre. The scanning sensor is essential for checking our prostheses, where high precision is crucial,” says Alexis Lecomte, Quality Control Manager at Dedienne Santé.

Significant gains in productivity and precision

The implementation of Hexagon’s solutions has brought multiple benefits to Dedienne Santé. It has increased precision as the CMMs meet the high-precision demands of the medical sector, ensuring each part conforms to stringent dimensional standards. The automated measurement process has resulted in a 20% reduction in inspection times, allowing operators to focus on other value-added tasks. For example, operators can run the inspection program and return to machining the parts, optimising the workflow.

The intuitive PC-DMIS software simplifies the inspection process, enabling operators to perform quick self-checking and automated in-process inspection and final control, improving ease of use.

“Hexagon’s solutions have significantly improved our productivity. For instance, inspecting a hip replacement cup now takes 20% less time, and we can perform inspections without constant supervision,” adds Lecomte.

Dedienne Santé values Hexagon’s precision, speed, and simplicity, as well as the ongoing support they receive. They also appreciate how Hexagon helps maintain high-tech manufacturing capabilities at their French Mauguio facility, ensuring they meet evolving production requirements.

“We must partner with suppliers who can help us maintain fast, productive manufacturing in France. Hexagon plays a key role in supporting our operations and ensuring we stay competitive in the global market,” says Ludovic Toledo, CEO of Dedienne Santé.

Dedienne Santé’s Commitment to Sustainability

Dedienne Santé is also committed to sustainable development and reducing its carbon footprint, as evidenced by its Coq Vert label, which recognises its efforts to minimise greenhouse gas emissions throughout manufacturing. With Hexagon’s solutions, Dedienne Santé can further its commitment to sustainability while maintaining top-tier manufacturing quality.

“We’re proud to have earned the French Tech label and the Coq Vert label, which reflect our ongoing dedication to innovation and sustainability. Hexagon’s support is crucial in helping us meet these high standards,” concludes Toledo.