🎧Efficiency forecasting is ‘key’ to OEMETA results

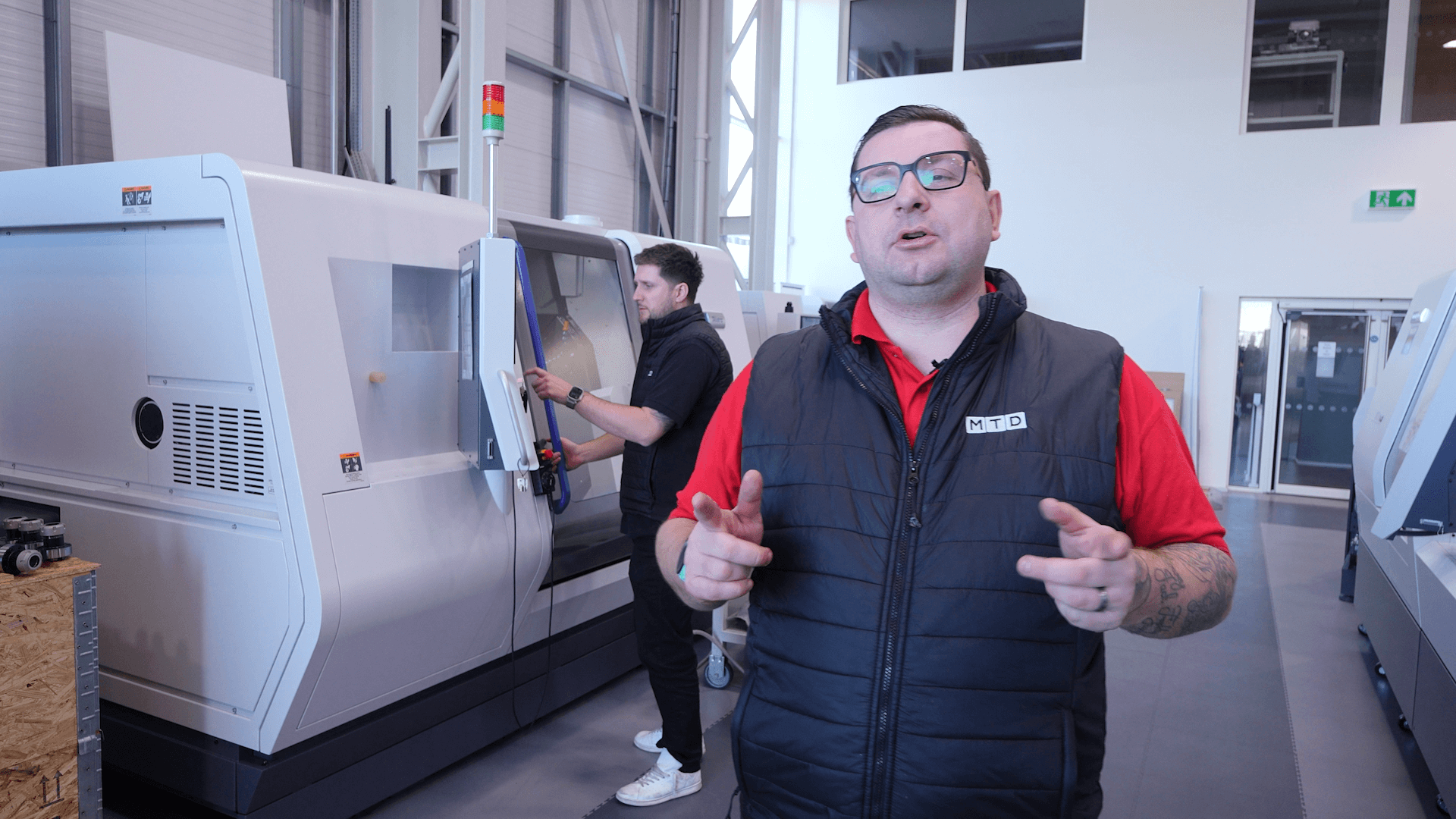

Key Precision is a subcontract manufacturer specialising in precision turned and milled components. Founded 21 years ago, the Cannock-based company focuses on driving efficiency throughout the business. Managing Director Greg Jackson identified cutting fluid performance as an issue needing attention—the solution was OEMETA’s ESTRAMET S95 coolant.

Greg says: “We have an impressive array of machines from sliding and fixed head turning to vertical machining centres.” The plant list boasts prestigious brands like Citizen, Hanwha, HAAS, DMG MORI, and Doosan.

Ryan Aviles from OEMETA explains: “Our relationship with Key Precision has been in place for years. Initially, we identified areas for improvement, and they invited us to trial.”

OEMETA’s engagement began with a consultative process where technical representatives evaluated the shop floor and collected samples for analysis. By taking fluid samples and sending them to OEMETA Germany for over 50 different tests, the process remains non-disruptive to production. The six-step process includes sample capture, performance analysis, result review, trial, product transfer and partnership. From this analysis, OEMETA yields a 95% success rate in delivering performance-enhancing solutions.

Following a consultation, OEMETA identified ESTRAMET S95 as the most viable solution. Compatible with steel, stainless and high-alloy steels, aluminium, and aerospace-grade alloys, ESTRAMET S95 serves the entire spectrum of applications, from drilling and milling to grinding.

Ryan adds: “On our first consultations we take samples, send them to Germany for analysis, and discuss results with the customer. Once we have sample results, we examine opportunities in detail. From our testing, we can benchmark against existing products and forecast benefits with confidence—before our product reaches their shop floor.”

Seismic Benefits from OEMETA

With testing covering lubricity, corrosion, stability, foaming, water quality, safety, and environmental impact, Key Precision experienced efficiency gains ranging from 35% to 150% across various operations.

Greg continues: “We’ve seen tool life improvements from 70% up to 150%. Every operation has shown a minimum improvement of 35%. For long-running jobs, U-drills saw a 77% increase. Parting-off efficiency increased by 35% and turning operations by 300%.” The extended tool performance has allowed the company to recoup its annual OEMETA fluid costs in the first month. Machine and component cleanliness and quality have also improved.

Based on synthetic ester oils, the translucent ESTRAMET S95 is free from mineral oil, boron, formaldehyde, fungicide, and active sulphur. This makes it a bio-sustainable, operator-friendly fluid. As a highly stable fluid, it has increased tool life from 20% to 50% on most machines, generating significant cost savings.

The implementation strategy incorporated a comprehensive approach, including bi-weekly site visits, laboratory testing, and compatibility assessments. OEMETA’s service model includes monthly coolant maintenance checks far beyond standard industry practices, with concentration verification, pH monitoring, microbiology testing, and tank evaluations.

Ryan explains: “We regularly revisit the site every two weeks to collect samples. With the results, we update customers on performance. Once KPIs are achieved, we start the roll-out process, taking samples from all machines to ensure compatibility with existing coolants.”

The success has prompted Key Precision to implement OEMETA across all water-based machining. Plans are also in place for oil-based solutions on sliding heads.

Ryan adds: “We’ve run tests on the sliding head machines and will deliver similar savings with our GTL (Gas To Liquid) product.”

Greg concludes: “The trial results speak for themselves. We’re committed to rolling out OEMETA fluids across our full range of machines. The results have been fantastic, and we look forward to more efficiencies and savings from working with OEMETA.”