Tru-Tech Precision Engineering make Excetek wire EDM investment based on trust

Tru-Tech Precision Engineering has established a reputation for quality and reliability within the high-tech industry sectors it supports. As well as the skills and expertise of its staff, the business stakes its longstanding reputation on the manufacturing equipment it relies upon. Here, an Excetek CNC wire EDM machine supplied by exclusive agent, Warwick Machine Tools, is meeting the demands set by the company.

Based in an impressive 5,000 ft2 facility in Dundalk, Co. Louth, Ireland, Tru-Tech Precision Engineering was originally established in 1996 to provide subcontract centreless grinding services predominantly to a number of customers in the medical device and technologies sector. Building an enviable reputation as one of the leading manufacturers of high precision mould inserts for the medical moulding industry.

However, as the requirements of the customers changed over the years the company has invested in additional manufacturing technologies to meet these needs. “That’s not to say that centreless grinding is no longer a key part of our business,” explains Managing Director, Joe Murphy. “Around half of our turnover comes from the high precision centreless and form grinding services we provide to various industry sectors.”

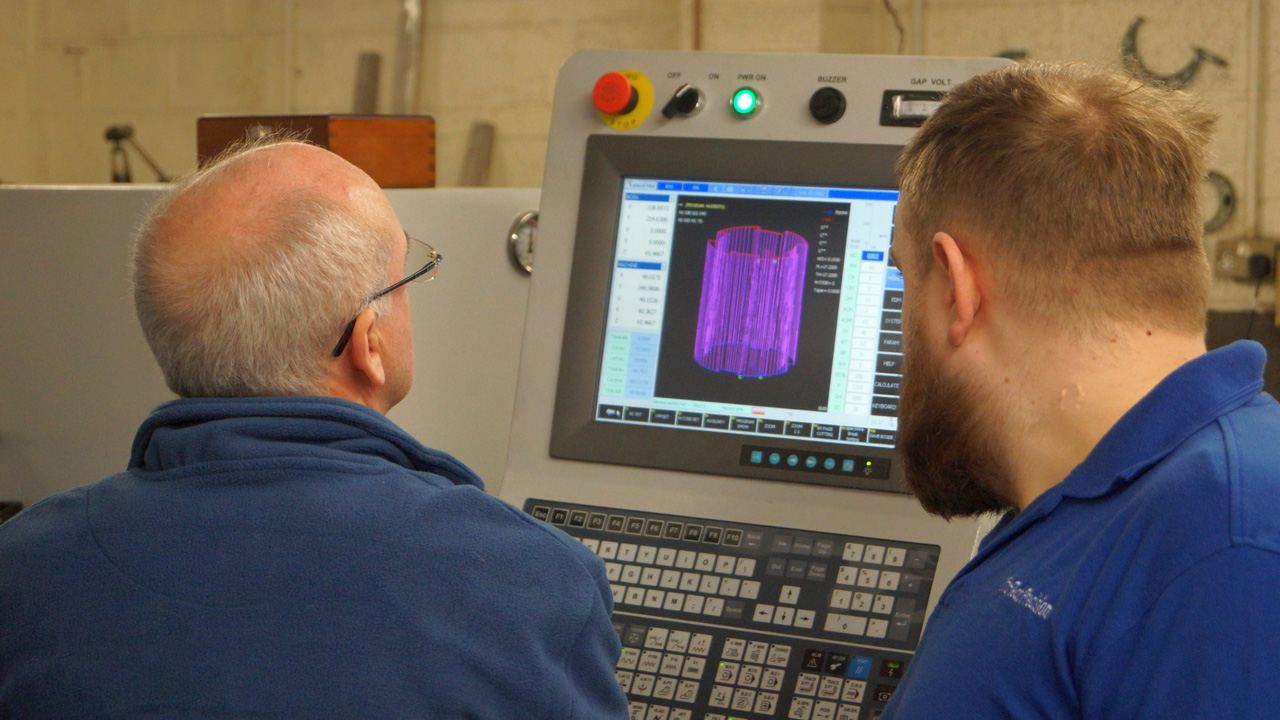

With an ongoing commitment to in-house research and development and continuous investment in training and technology, Tru-Tech has equipped itself to meet and often exceed the growing demands of an increasing customer base that includes medical and healthcare, automotive, electronics, computing and telecoms. Alongside the CNC milling and turning machines on the shopfloor, a CNC EDM die sinking machine supports the company’s ability to provide precision single and multiple mould tool cavities.

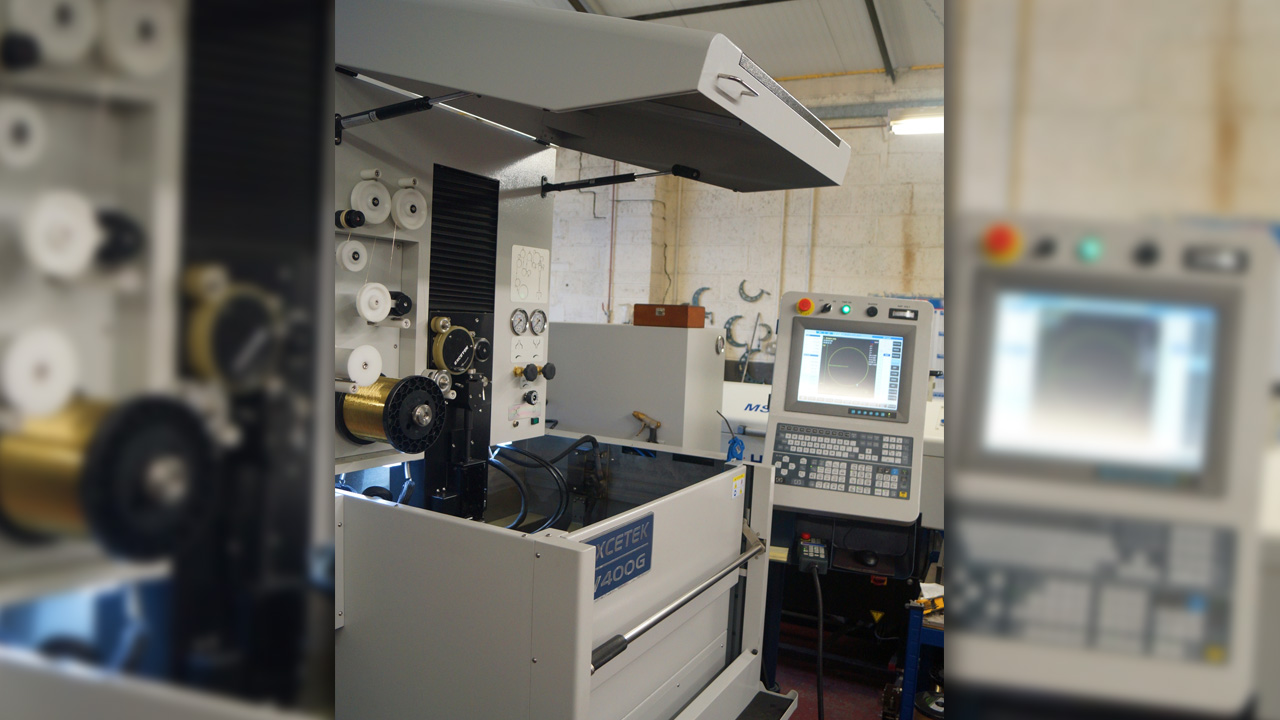

Joe Murphy recalls: “We have used an ONA die sinker for many years, and Warwick Machine Tools’ sales and service engineer, Paul Barry, has always been on hand to look after the machine for us. Keeping it operating around-the-clock to match our workload. He was aware that we were having some issues with an old wire cut machine that was unreliable and expensive to repair, as well as being very slow in operation when it was working. During a visit to our facility he mentioned the new Excetek V400G CNC wire cut machine, and on paper the cost-to-performance ratio looked unbeatable.”

Providing comparative performance levels to the existing Swiss and Japanese wire EDM machines, the new Excetek V400G offers a major cost saving against any equivalent size machine tool, and the price includes training and installation. The new V400G has travels of 400 mm the X-axis and 350 mm in the Y-axis to 350 mm. It is capable of accommodating larger workpieces up to 750 x 550 x 215 mm weighing up to 500 kg with a compact overall footprint.

All the standard range of wire EDM machines from Excetek feature a C-frame structure designed using FEA software to provide exceptional accuracy in the linear axes movements and to minimise any thermal influence. The new V400G features a honeycomb frame structure for rigidity and thermal stability. The AC servo motor driven C1 class ball screws are cryogenically treated to minimise the thermal effects of the machine’s ambient operational environment, with high accuracy linear scales fitted for accurate positional feedback.

The machine also features Excetek’s latest corrosion-free electro discharge generator technology that improves cutting performance. While the cutting speed of every wire EDM machine is limited by the laws of physics and set by the thickness of the raw material being cut, it is a manufacturer’s corner control that defines its machine accuracy. Excetek’s software ensures the motion control and spark generator work together for the optimum power ramping and compensation dwell on corners, avoiding wire twist and reducing corner ‘washout’. Wire diameters from 0.15 to 0.3 mm can be used and for extended operation a 50 kg jumbo wire feeder can also be fitted.

Joe Murphy explains: “The machine is very keenly priced, and we were sending around 10,000 Euros of wire work out every month and, although the quality was good, we had very little control over the lead times. Now we have the ability to carry out the work in-house we can control both the costs and the timescales.”

The build quality and specification of the Excetek range is impressive and for Tru-Tech the Automatic Wire Feed means the machine can run ‘lights out’ all through the night to ensure customers get their parts on time. The AWT offers the ability to thread the wire at the point of the breakage. An automated annealing system straightens the wire so that it can be threaded at the break point during machining with almost 100 per cent reliability and without the need to return to the start position. Submerged wire threading is possible, which removes the need to drain and refill the tank. A water jet assist system is available for automatic wire feeds on tall workpieces.

As well as the ability to produce very accurate and detailed copper electrode for the die sinking machine the wire EDM has provided a further benefit with its ability to cut form grinding dressing blades from Syndite. A composite material that combines the hardness, abrasion resistance and thermal conductivity of diamond with the toughness of tungsten carbide, Syndite blades could take a couple of hours to produce on a digital Optidress wheel forming dresser. Using the Excetek V400G, Tru-Tech can now generate the blades in less than half an hour.

“The positive long-term relationship we have with Paul Barry was the foundation for the investment in the Excetek machine, we trust his reputation and made the choice knowing that he is based here in Ireland so any support required would be readily available,” Joe Murphy concludes.