EMAG Group introduces the MRC robot cell, a groundbreaking innovation set to redefine flexible automation in manufacturing. Unlike traditional automation solutions, the MRC is engineered to offer more than just robotic integration. It provides a suite of features designed for adaptable manufacturing environments, including standardized interfaces, reproducible processes, and minimal engineering demands.

Central to the MRC’s design is its capability to seamlessly connect with various feeding systems, from pallets to bulk goods. This flexibility is supported by a standardized gripper and flange concept, enabling manufacturers to efficiently manage a diverse range of workpieces. Additionally, advanced software functions are integrated to facilitate automatic position calculation and palletizing, enhancing overall efficiency and productivity.

A standout feature of the MRC is its ability to maintain its core structure even as production demands change. This makes it ideally suited for settings where product variety and volume are in constant flux. Its versatility ensures that the MRC can adapt to new workpieces, providing manufacturers with the agility they need to stay competitive in a rapidly evolving market.

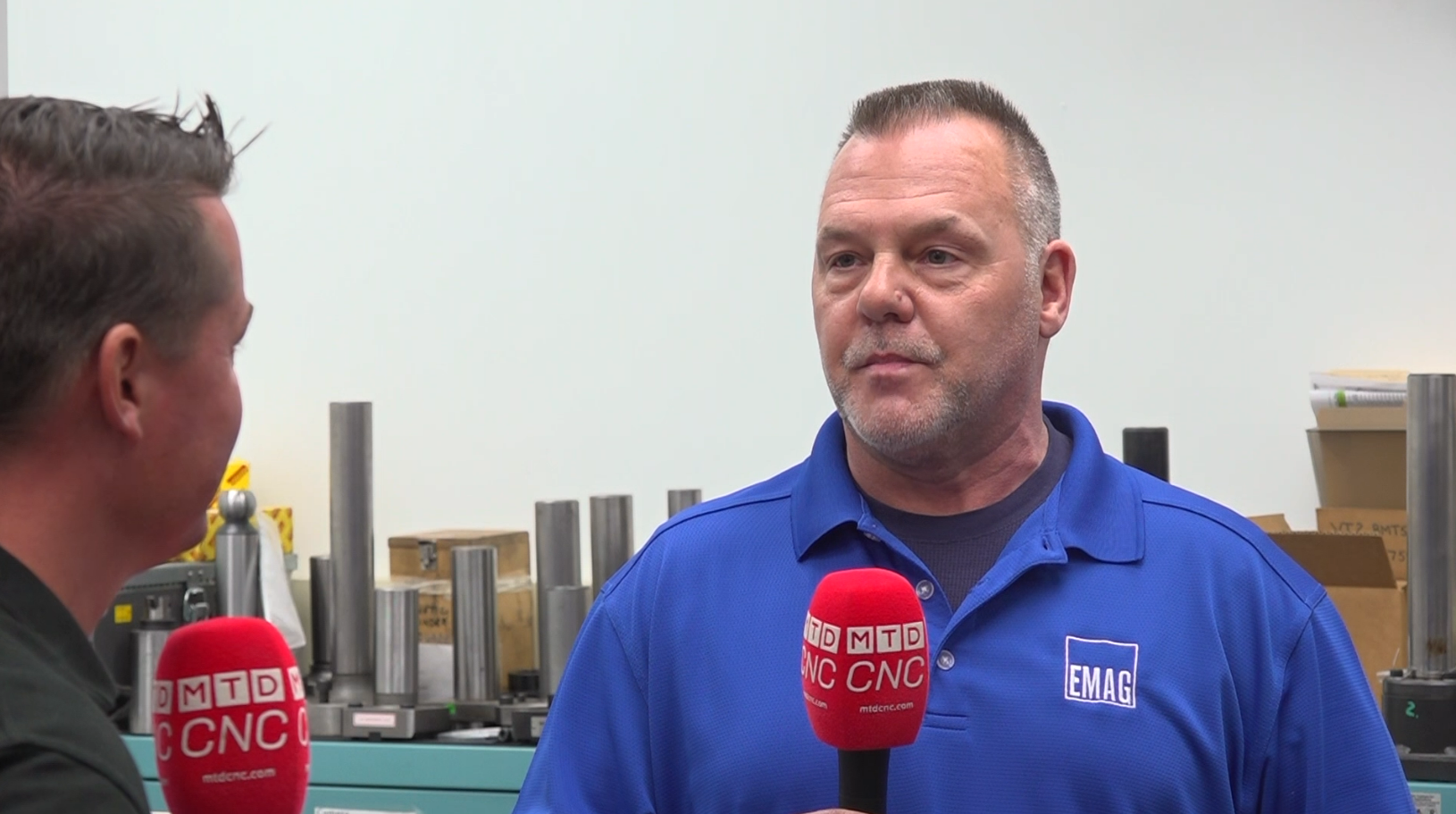

EMAG is known for its commitment to engineering excellence, and the MRC robot cell is a testament to this legacy. By providing a robust solution that combines flexibility with precision, EMAG continues to support manufacturers in maximizing their operational capabilities and achieving sustainable growth.

View more news from EMAG Group