- EMO 2025as

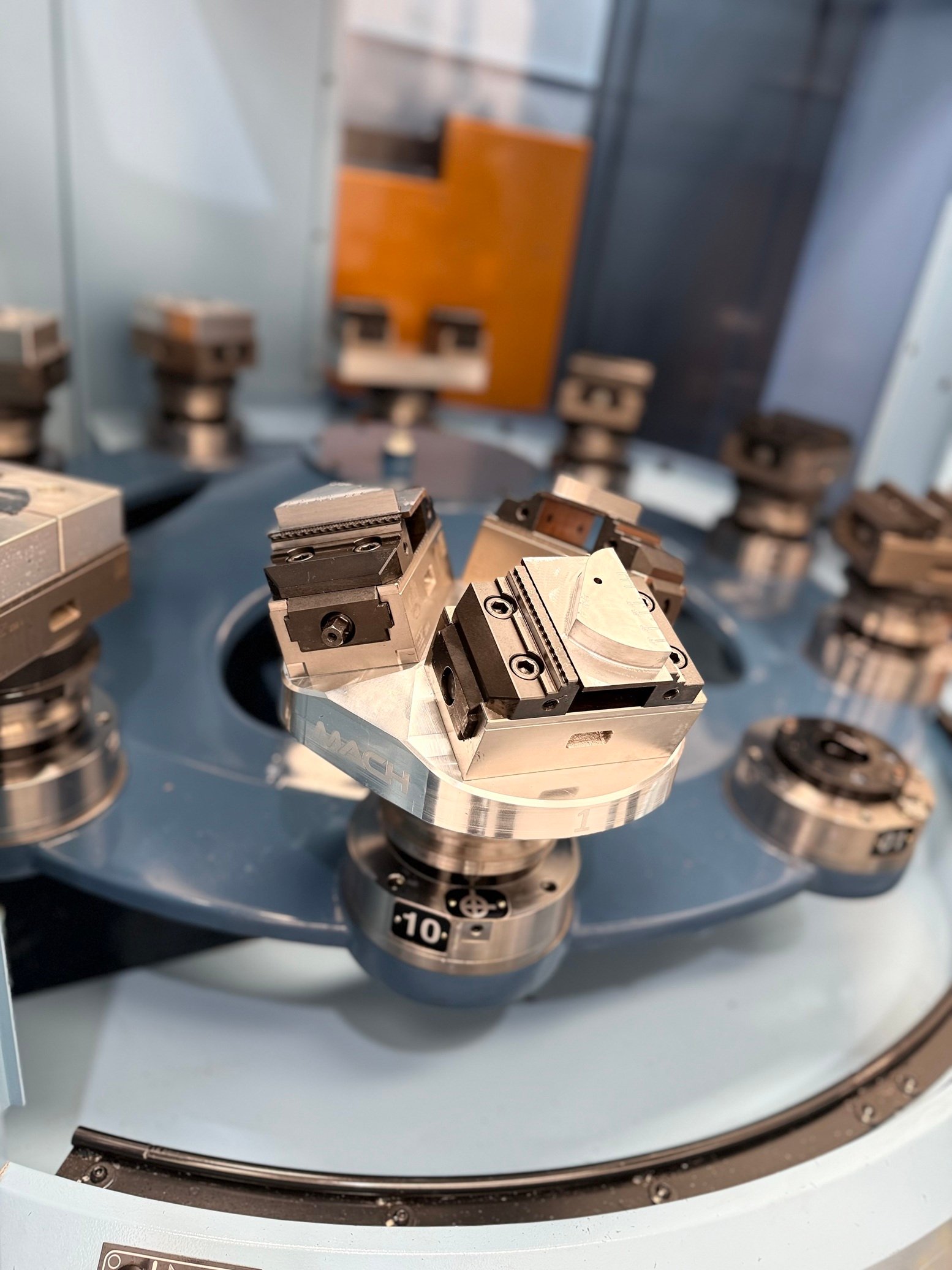

DelphinCompact: heavy-duty workholding with process security built in!

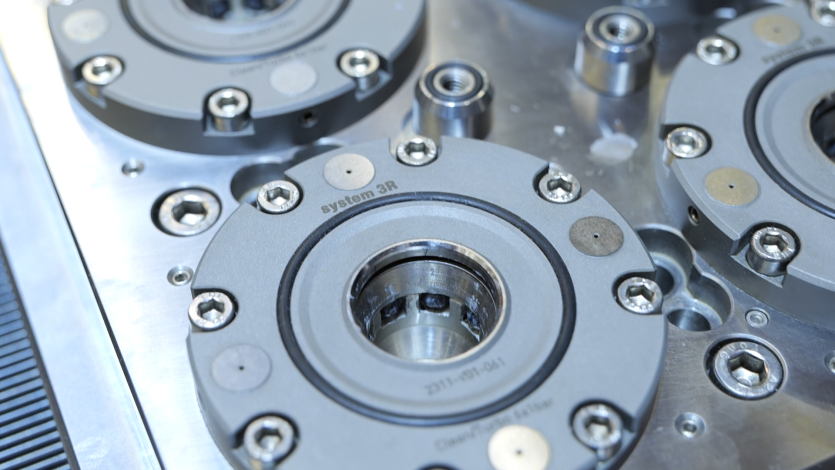

For big, heavy components, System 3R’s DelphinCompact guarantees process security, reliability, and peace of mind on every job. We’re talking heavy-duty, automation-ready workholding built for up to 600 kilogram payloads. Rowan Easter-Robinson of MTDCNC and Henrik Nordquist of System 3R walk us th…

Lyndsey VickersLast viewed

Lyndsey VickersLast viewed - EMO 2025as

DelphinShort from System 3R – small, smart, and automation-ready!

System 3R demonstrates why the DelphinShort isn’t just any work holding – it’s compact, reliable, and built for automation. Pneumatic clamping and flexible pallet options make loading parts fast, whether by hand or robot. Customers also get repeatable accuracy, high clamping force, and the ability…

Lyndsey VickersLast viewed

Lyndsey VickersLast viewed - EMO 2025as

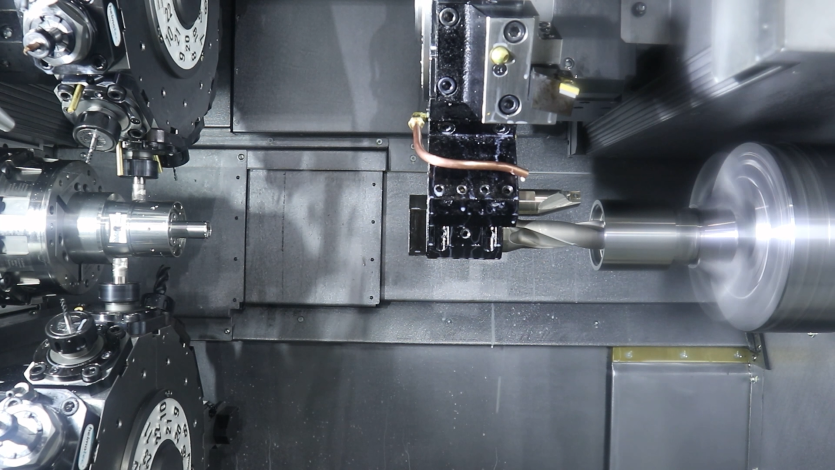

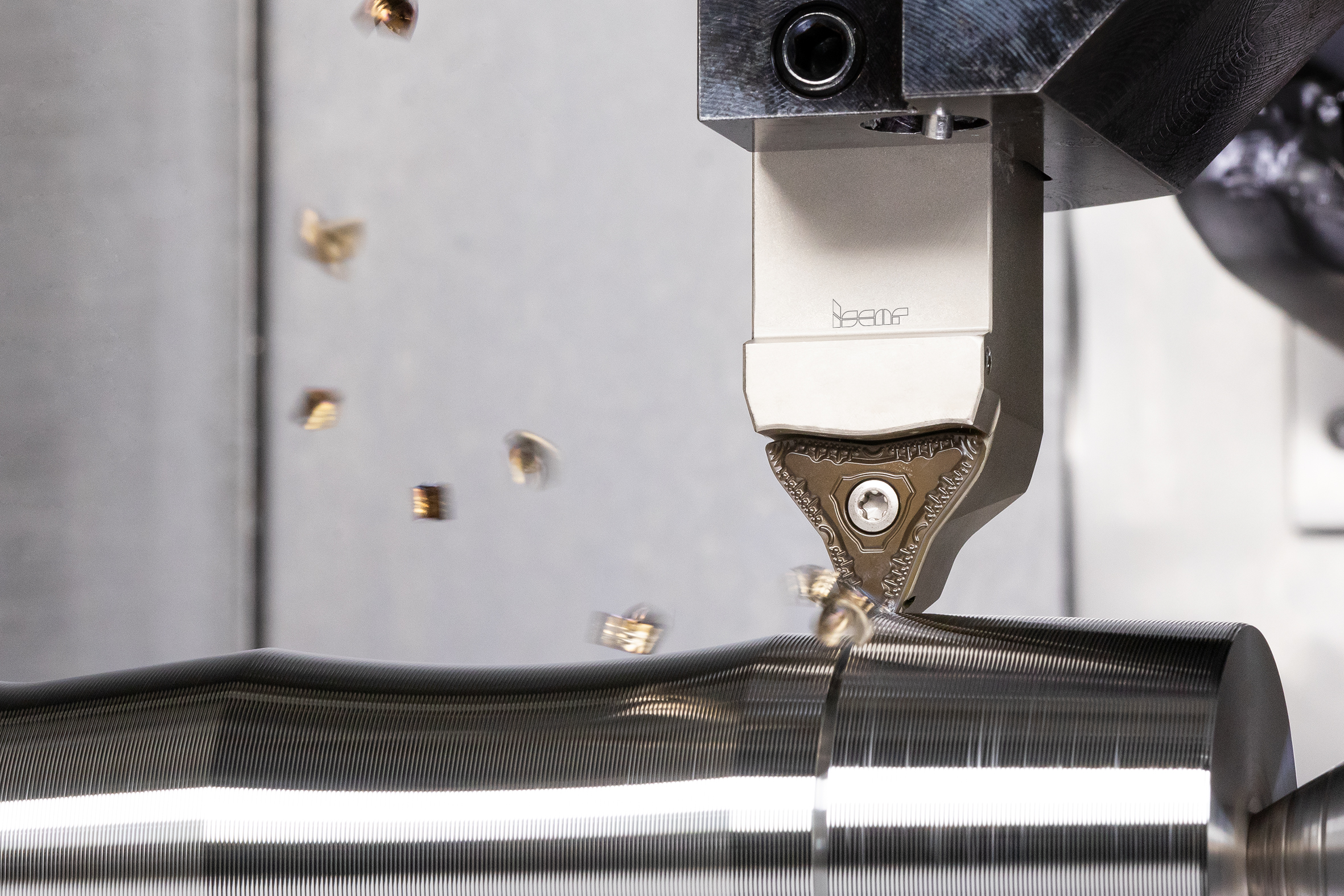

This Nakamura cuts idle time by up to 30%?!

Higher RPM and more torque: a bigger machine that runs up to 30% faster by cutting idle time alone. That’s exactly what Jundi Oyama from Nakamura-Tome explains – from ChronoCut software and upgraded servos to smarter motion and faster acceleration. Add turret crossover, compact automation for over…

Arthur FieldLast viewed

Arthur FieldLast viewed

SA

Popular

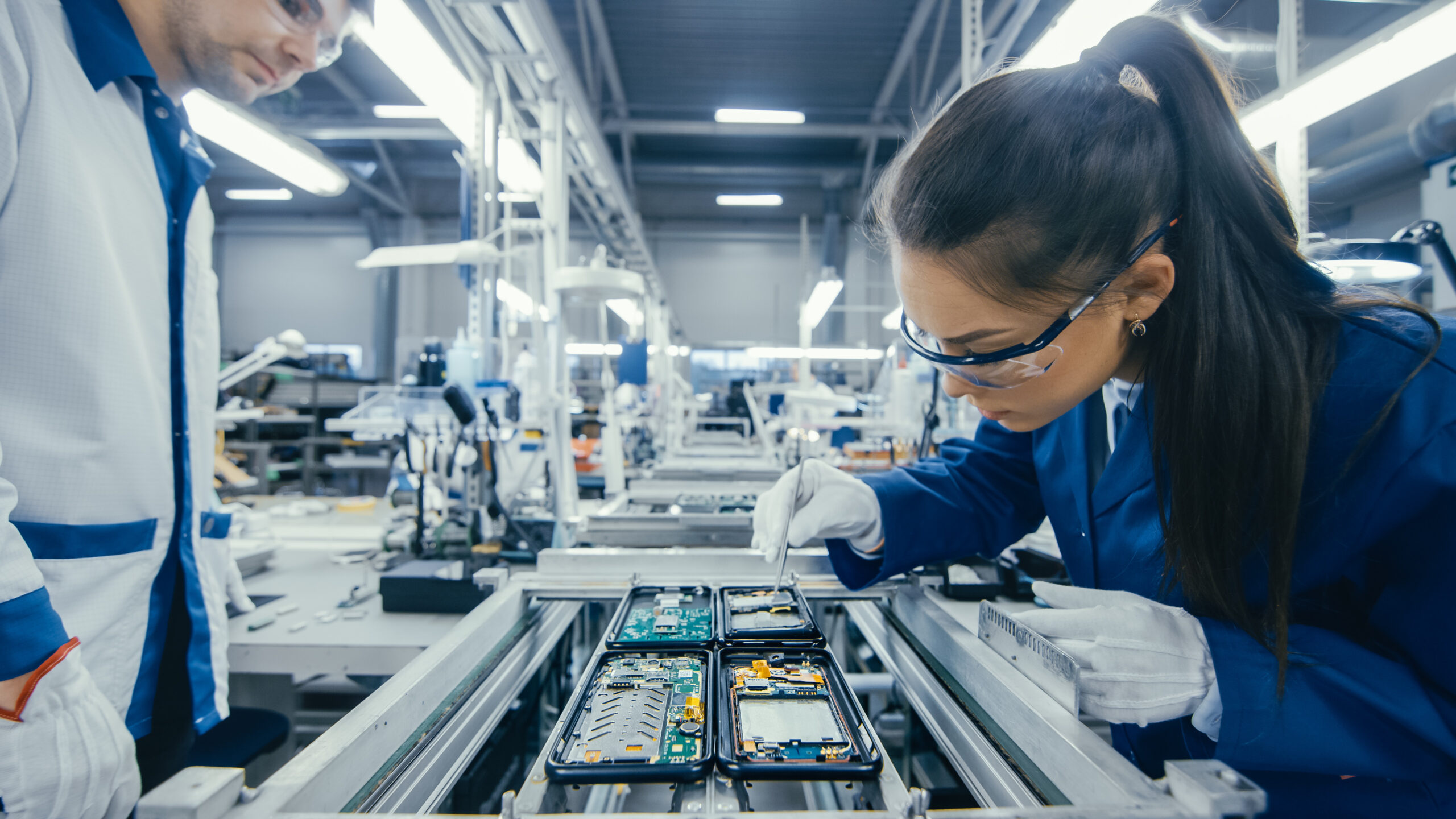

Mazak Showcases Advanced Solutions at Expo Manufactura 2026

Mazak North America is making waves at EXPO MANUFACTURA® 2026, inviting manufacturing enthusiasts to experience cutting-edge technology at booth 2702. The event, which is taking place now, provides a platform for industry leaders and innovators to converge and explore the future of manufacturing. Mazak is showcasing the VC-Ez 16X and QT-Ez 12MY models, equipped with the Ez LOADER technology. These advanced machines exemplify the company’s commitment to enhancing production efficiency and expanding shop capabilities. The VC-Ez 16X and QT-Ez 12MY are designed to boost throughput and provide manufacturers with the confidence to progress in a competitive market. The Ez Series

MTDCNCLast viewed

MTDCNCLast viewed

HAIMER México Showcases at EXPO MANUFACTURA 2026

HAIMER México is making a significant impact at EXPO MANUFACTURA 2026, the premier manufacturing event taking place in Monterrey. Known for its commitment to quality and innovation, the company is eager to connect with industry professionals and demonstrate its advanced technologies at this renowned gathering. Positioned at Booth 218 in Cintermex, HAIMER México is focused on showcasing solutions that enhance manufacturing processes, emphasizing stability, repeatability, and productivity. As a leader in the field, HAIMER is dedicated to improving production workflows for manufacturers who aim for precision and efficiency in their operations. EXPO MANUFACTURA, a key event for the manufacturing sector

MTDCNCLast viewed

MTDCNCLast viewed

German Tool Grinder Expands with VOLLMER Technology

For over fifty years, Schärfdienst Angeln e.K. has relied on VOLLMER technology to ensure precision and reliability in its tool grinding services. Known as Germany’s northernmost tool grinding facility, the company serves a diverse customer base of over 900 clients across industries such as wood, metal, plastics, and food processing. With a focus on sharpening expertise, Schärfdienst Angeln boasts a modern machine portfolio including the CHX 840 and CHC 840 models. These machines highlight the company’s commitment to precision when it comes to craftsmanship and technology. Key features such as consistent accuracy, reliable spare parts availability, intuitive machine operation, and

MTDCNCLast viewed

MTDCNCLast viewed

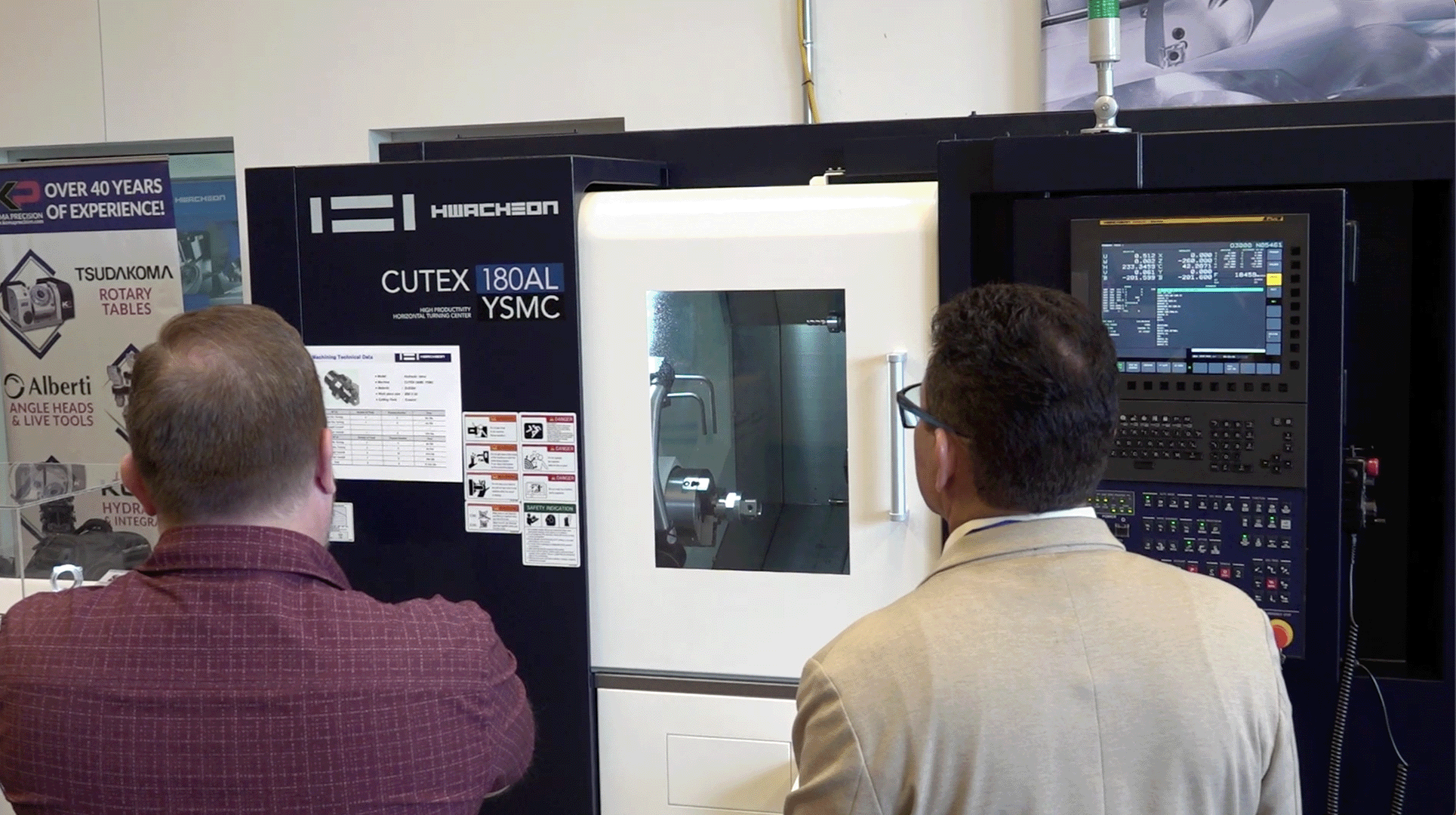

Kitamura and Grupo HITEC Unveil Cutting-Edge Tech at Expo Manufactura

Kitamura Machinery, in collaboration with their partner Grupo HITEC, is making waves at Expo Manufactura in Monterrey, Mexico. The event, held from February 3-5, is a prestigious platform for the manufacturing industry, showcasing the latest advancements in technology. Grupo HITEC’s booth at the expo is attracting attention with its display of the Mycenter-HX250iG, a highly advanced horizontal machining center from Kitamura. Renowned for its ultra-compact design, the Mycenter-HX250iG is equipped with innovative technology that significantly enhances production performance. This machine is designed to meet the demands of various industries, offering precision and efficiency in machining processes. Visitors are encouraged to

MTDCNCLast viewed

MTDCNCLast viewed

Inside the DMG MORI Open House 🇩🇪

Lyndsey, Tom, and the MTDCNC team are in Germany this week attending the DMG MORI Open House—an annual fixture in the MTDCNC event calendar and, without doubt, one of the most impressive industry events of the year. With incredible world premieres, cutting-edge innovations, thousands of visitors, and outstanding hospitality, the DMG MORI Open House consistently sets the benchmark for how manufacturing events should be done. We’ll be bringing you plenty of in-depth content over the coming weeks, including machine highlights, new technology launches, and expert insight straight from the show floor. For now, here’s a sneak peek at what’s happening—there’s

Lyndsey VickersLast viewed

Lyndsey VickersLast viewed

Tebis Hosts Global Meeting Focused on Innovation

Tebis AG recently hosted its annual meeting, spotlighting the theme “One Voice, One Message 2026.” This gathering brought together sales, marketing, and technical colleagues, emphasizing the importance of unified communication and collaboration. The event provided an opportunity for Tebis staff to explore innovative technology solutions and share insights with international colleagues. The discussions and exchanges were described as inspiring, reflecting a shared commitment to progress and excellence in the field. In addition to formal meetings, the weekend offered a chance for team-building activities. Participants traveled to Seefeld, Austria, where they enjoyed hiking and skiing amidst stunning mountain views. These activities

MTDCNCLast viewed

MTDCNCLast viewed Latest News Americas

What MTDCNC can do for you

Your partner for marketing, media, and events in manufacturing.

Podcast

Here at MTDCNC, you’ll find a collection of top-notch podcasts featuring discussions and insights from the manufacturing market.

How fast can your machine builder get you running again?

You know you’ve got the right partner when uptime is built into their entire service philosophy! That’s what Starrag is all about. In today’s podcast, MTDCNC’s Arthur Field talks with Rob and Steven of Starrag about how their team classifies parts, manages everything through their ERP system, and ships critical replacements straight from their Kentucky warehouse. From a flooded vertical turning center to modernizing a 1970s machine to 2025 standards, their service stories are proof that Starrag keeps customers’ machines running. Tune in to learn how smart stocking, global technician coordination, and precise ticket tracking help Starrag react fast when

What’s the difference between a supplier and a partner?

They don’t just sell a machine and drop it on your shop floor — Starrag runs the entire journey as a full project. In this MTDCNC podcast, Arthur Field sits down with Udo and John of Starrag to unpack how the company delivers almost 24/7 cross-continental project management, structured kick-off meetings, and deep technical support. With around 70% of their North American business in defence and ITAR and over 70 machines supporting programs like the F-35, Starrag brings the engineering strength to handle everything from tooling and turnkey programming to massive foundations. Tune in to learn how Starrag becomes a

They’re bringing BIG updates to the North American market!

From compact series machines and powerful five-axis platforms to the revolutionary Matrix Tool Magazine holding up to 828 tools, Starrag is delivering complete solutions for the shop floor. MTDCNC’s Arthur Field sits down with Udo Herbes and Jim Stolo at Starrag’s Kentucky HQ to unpack everything new for the North American market: RCS CAM software, more hands-on factory training for service techs, expanded support across North America and Mexico, and more. If you’ve ever wondered what it takes to keep high-end manufacturing ahead of the curve, this MTDCNC podcast with Starrag is one you can’t miss! Interested in hearing some

The Best Investment You’ve Never Heard Of: Why MEP Is Saving U.S. Manufacturing!

Quietly operating in the background of American manufacturing is one of the nation’s most effective programs, NIST’s Manufacturing Extension Partnership (MEP). Designed as a public–private network, MEP helps small and medium-sized manufacturers modernize operations, embrace technology, and compete in a global economy that’s changing faster than ever. While large corporations often have access to consultants, engineers, and global supply chains, smaller manufacturers typically work with tighter budgets, limited expertise, and far less time. That’s where MEP steps in. With a nationwide network of nearly 1,400 experts and thousands of affiliated organizations, the program connects manufacturers of every size and specialty

Drills, Thrills, and Swiss Skills — Mikron Tool Takes the Mic with Tony Gunn!

What happens when Swiss precision meets American podcast energy? A whole lot of mic-dropping, tool-spinning, high-speed conversation—because Mikron Tool is officially joining The Gunn Show podcast! The world-renowned masters of micro machining are stepping behind the mic to talk shop, and this isn’t just a drill (pun absolutely intended). We’re diving into the cutting-edge (literally) innovations that make Mikron Tool the go-to name in ultra-precision tools for small part machining, high-speed applications, and complex materials like titanium and Inconel. We’re bringing the banter, the behind-the-scenes stories, and the bold truth about what it takes to be a global leader in

Open House, Open Minds, Open Conversations

Welcome to The Gunn Show Podcast: Spring Fling Edition, where machines roared, brisket sizzled, and conversations got real. Filmed live from the BIGGEST Open House in Texas, this episode features the amazing crew at Prosper Machine Tools, who did more than just throw a party, they threw open the doors to some of the most honest, heartfelt, and thought-provoking conversations we’ve had all year. Yes, we talked machines. Yes, we geeked out over automation, accuracy, and innovation. But we also peeled back the shop rag to reveal the deeper stuff—politics, tariffs, gratitude, and expectations in today’s uncertain global economy. We