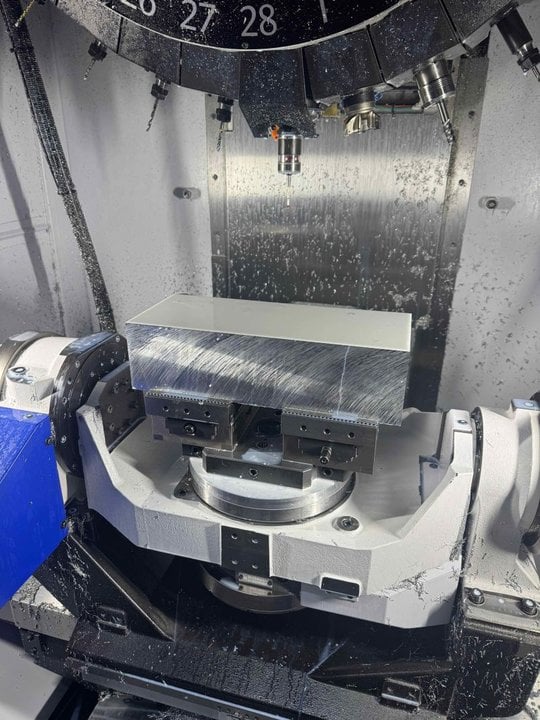

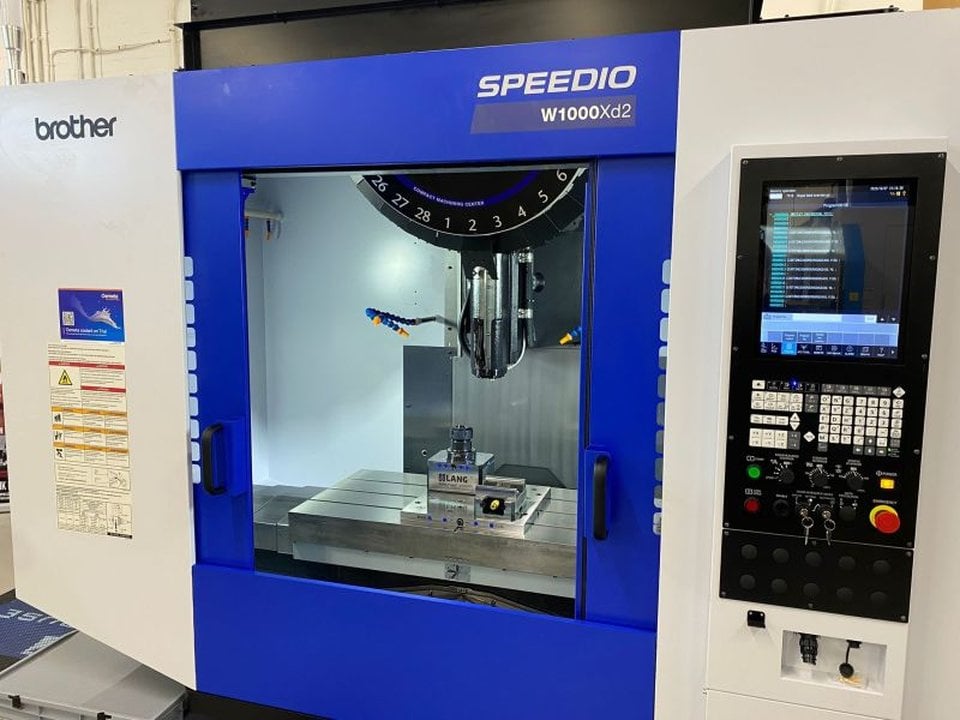

Glenair has enhanced its manufacturing capabilities with the addition of two Brother U500Xd2 5-axis machining centres. These state-of-the-art machines are set to improve flexibility, precision, and efficiency, supporting Glenair’s delivery of mission-critical interconnect solutions.

The arrival of the Brother U500Xd2 models signals a significant upgrade in Glenair’s production line. Renowned for their reliability and precision, these machines are ideal for complex milling tasks and enhancing production efficiency. They feature advanced automation and are designed to meet a wide array of manufacturing needs, ensuring Glenair stays at the forefront of the industry.

The successful delivery and installation of these machines were made possible by the expertise of Whitehouse Machine Tools. Special acknowledgment is due to Dan Hayes and Daniel Price from the applications team, whose efforts ensured the seamless integration of the machinery.

Brother Machine Tools, a leader in CNC technology, continues to provide innovative solutions designed to meet the dynamic needs of the manufacturing sector. Their U500Xd2 model stands out for its combined capabilities in 5-axis machining, allowing for more precise and versatile production processes.

Glenair’s investment in the Brother U500Xd2 reflects its commitment to maintaining high standards in manufacturing quality and delivery. This move not only bolsters Glenair’s production efficiency but also reinforces its reputation for delivering high-quality interconnect solutions.

Whitehouse Machine Tools, known for its expertise in machine tool distribution and servicing, supports leading manufacturers across various sectors with cutting-edge solutions and exceptional service.