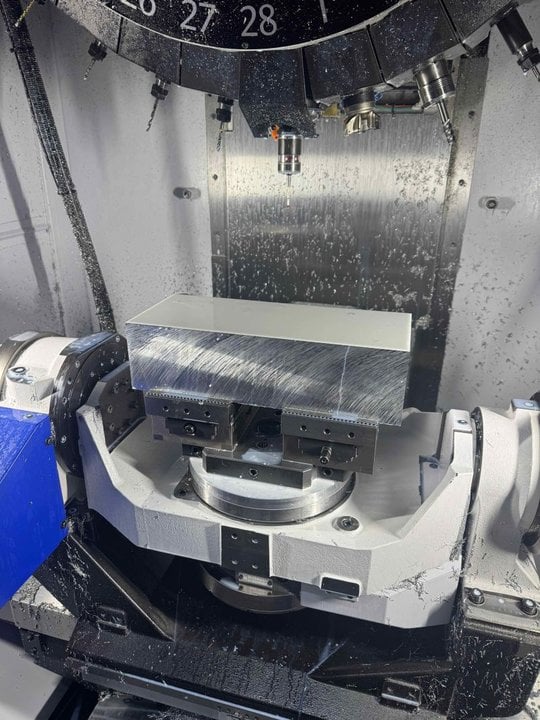

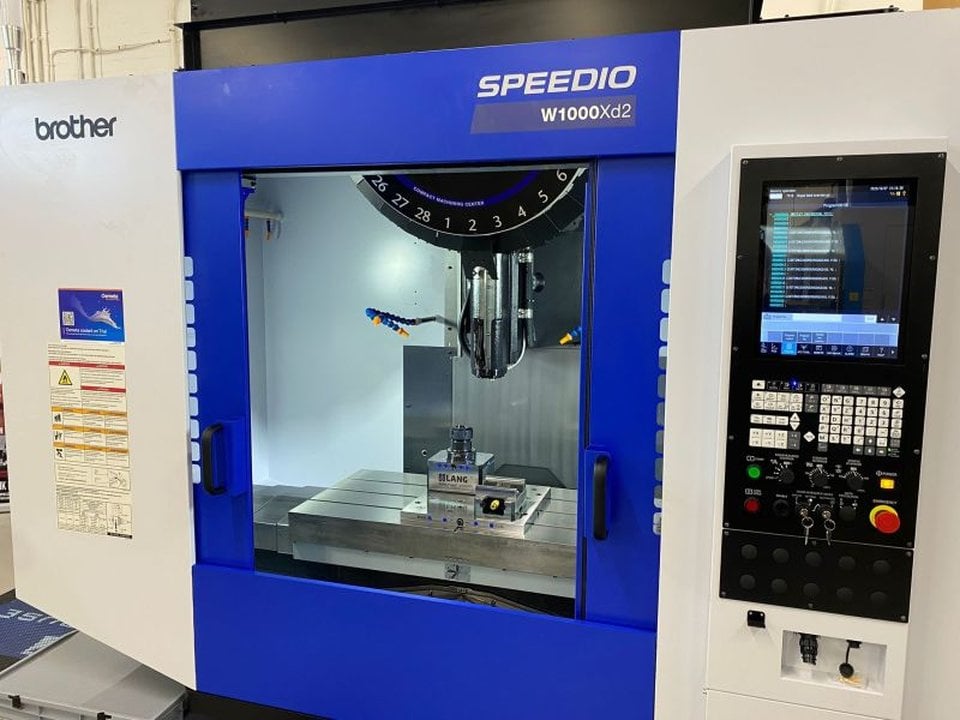

Atkinson Equipment Ltd has made significant strides in reducing lead times through automation in their prismatic machining processes. By investing in the Brother Speedio U500Xd1 5-axis machining centre, complemented by Tezmaksan CubeBox automation, the company has significantly improved efficiency.

The adoption of these technologies has resulted in a dramatic reduction of lead times for complex subcontract parts from 12 weeks to just six weeks. Additionally, for their in-house products, lead times have been cut from one month to a mere week. This innovation marks a substantial shift in operational dynamics, highlighting the efficacy of combining advanced machining centers with automated solutions.

Brother Machine Tools Europe, known for their state-of-the-art CNC machines, provided the Speedio U500Xd1, renowned for its precision and adaptability. Tezmaksan, a leader in robotic technologies, contributed the CubeBox automation, ensuring a seamless integration and enhanced workflow.

Whitehouse Machine Tools, associated with both Brother and Tezmaksan, supported the implementation. The partnership underscores the importance of collaboration in driving technological advancements within the machining and manufacturing industry. This case study not only exemplifies the transformative impact of automation but also encourages industry peers to explore similar investments for operational efficiency.

Atkinson Equipment’s success story serves as a noteworthy example within the manufacturing sector, reinforcing the benefits of modern automation solutions tailored to specific industry needs.