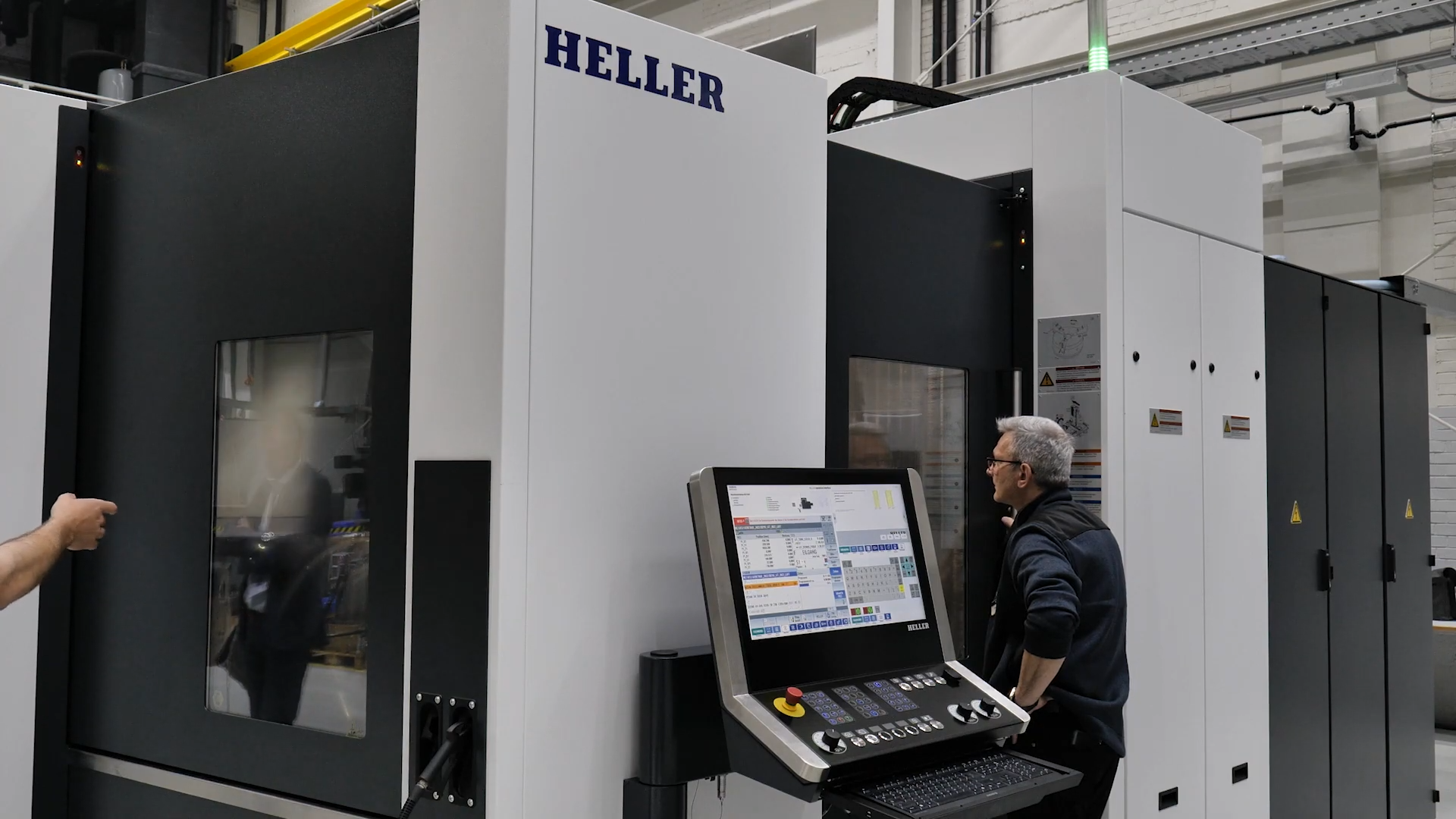

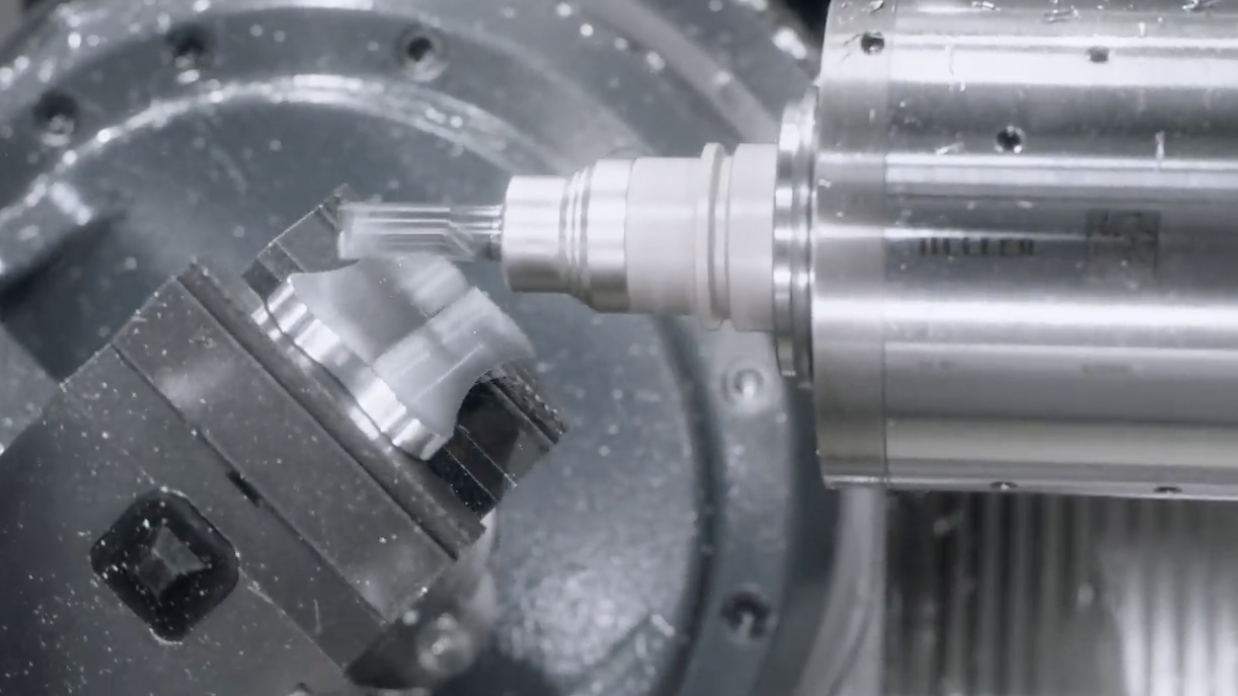

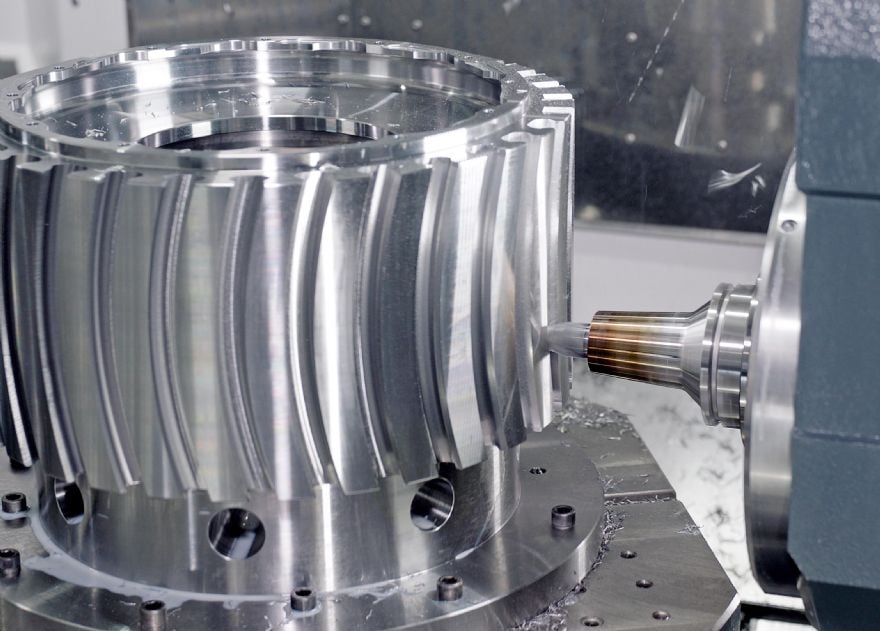

HELLER has launched the new F 6000 5-axis machining center at EMO, representing the next generation of the F series. This machine offers increased cutting performance, higher precision, and reliability for 24/7 production. It features advanced components such as newly developed spindles, heads, and tables, ensuring compatibility with previous models. The F 6000 is designed for versatile applications, including mill/turn operations, and is equipped with spindle units capable of speeds up to 15,000 rpm. The machine also boasts improved linear axes dynamics, reduced positioning tolerances, and an efficient automation-ready design.

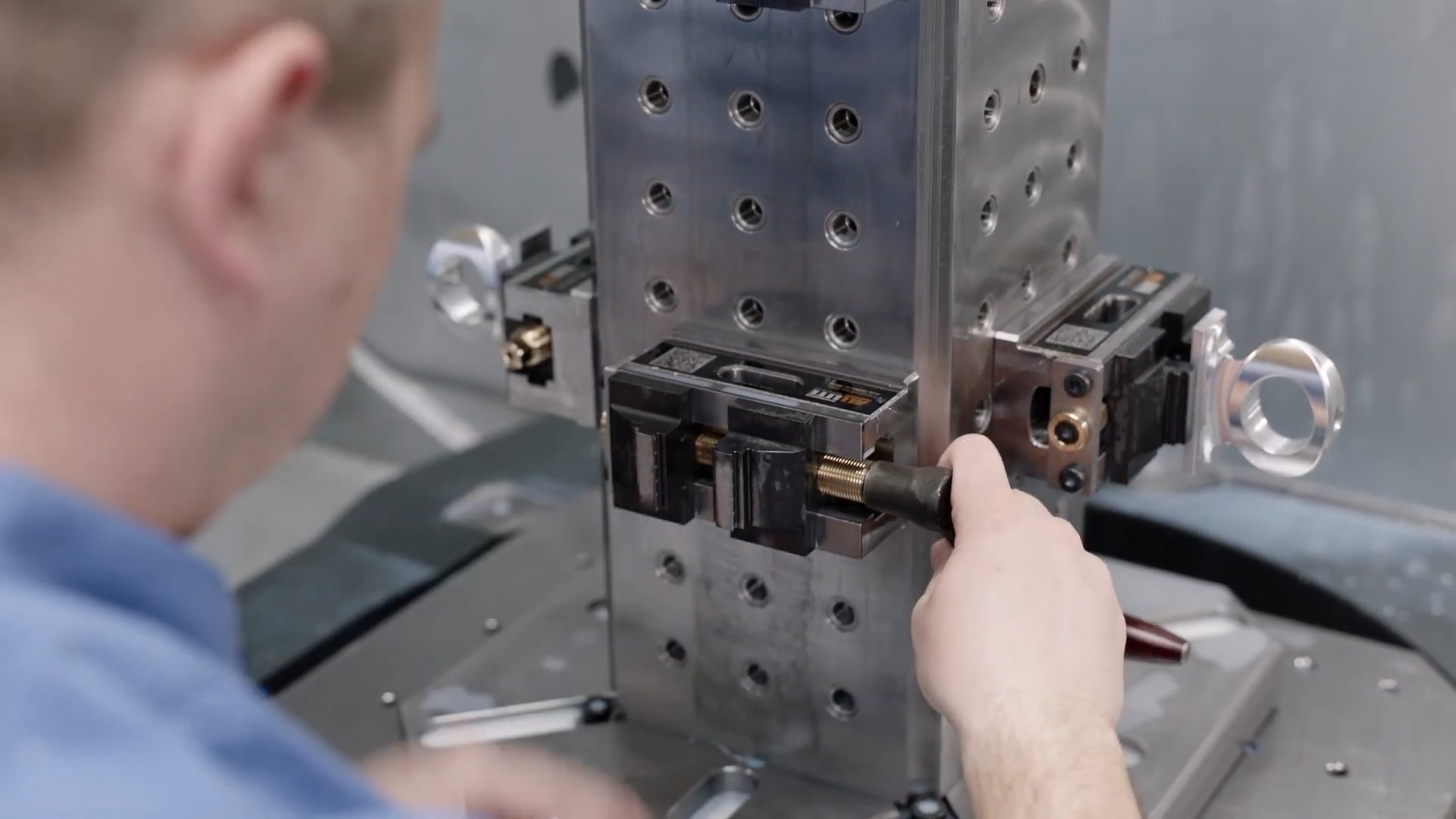

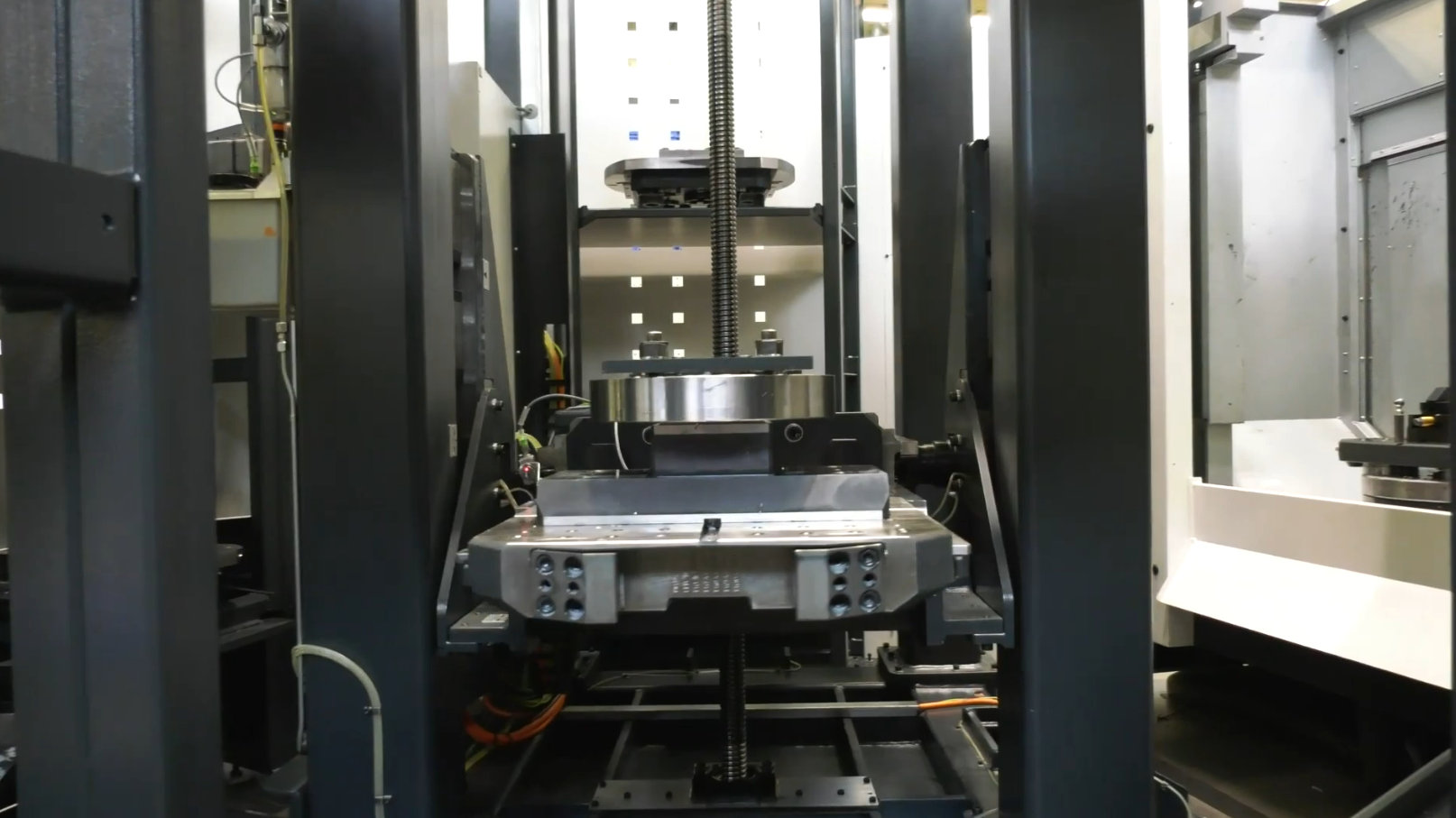

Dr. Eng. Manuel Gerst, Head of Development at HELLER, emphasized the high standard achieved with the F 6000, highlighting its adaptability for various machining needs, from heavy-duty cutting to light metals. The F 6000’s modular design allows it to be tailored to specific customer requirements, ensuring maximum productivity. The machine integrates a high-speed DDT rotary table for combined milling and turning operations, enhancing precision and reducing production times.

HELLER’s new F 6000 also prioritizes ease of operation with features like a 24-inch touch screen, wider work area door, and bright lighting. The Siemens SINUMERIK ONE control system ensures compatibility with existing NC programs from previous F- and C-series machines. Additionally, the machine’s automation capabilities include a standard pallet changer and options for retrofitting with linear or rotary storage solutions.

For more detailed insights, visit HELLER’s official page.