Application – Protect ️ and improve Press Shop OEE with Contrinex Double-Sheet detection sensors

Contrinex Double-sheet detection sensors protect ️ press lines and improve OEE

Contrinex’s innovative sensors provide affordable detection of overlapping metal sheets. They can protect a press-line by checking that two metal blanks are not presented to the forming press, or alternatively ensure two pieces of metal are present for example in an automotive welding assembly – Sometimes two’s too many, but sometimes you just need two – Read more at http://Double.PLUSAx.co.uk

CUSTOMER APPLICATION

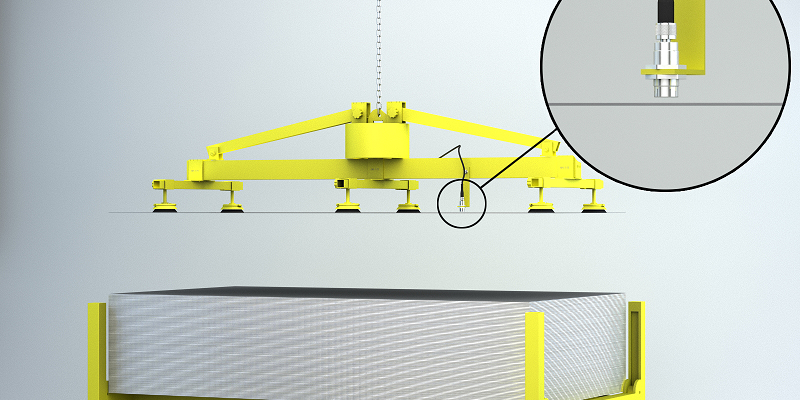

A producer of deep-drawn metal parts for the automotive industry uses Contrinex’s double-sheet sensing to prevent costly tool damage and downtime.

Deep drawing and other metal-forming techniques are widely used in the automotive industry, which requires expensive press tools to produce complex profiles from sheet metal blanks. During high-volume production, an automated feeder loads sheets of steel or aluminium to the press.

The metal sheets are lightly lubricated to reduce friction during deep drawing, but the thin film of oil can cause two sheets to stick together in the feeder. If the press operates with such double sheets loaded, the forming tool will be damaged, resulting in downtime and large repair costs. Therefore sensing systems are used to check the material before it is loaded.

Previously, the customer had trailed alternative sensor technologies. All were excessively cumbersome and difficult to set up, and most were unable to detect double sheets reliably.

CUSTOMER SOLUTION

Contrinex offers a rugged, compact stainless-steel -bodied sensor for the loading station, which checks each metal sheet as it is presented by the feeder. If it detects a double sheet, the material is rejected and the operating cycle inhibited, which reduces expensive damage to tooling and improves OEE.

Contrinex offers a rugged, compact stainless-steel -bodied sensor for the loading station, which checks each metal sheet as it is presented by the feeder. If it detects a double sheet, the material is rejected and the operating cycle inhibited, which reduces expensive damage to tooling and improves OEE.

The sensor enables discrimination between single and double metal sheets of a defined thickness of steel or aluminium in the size range of 0.8 – 1.2mm thick.

A specialist version of Contrinex’s uniquely robust ‘700 Series’ family of inductive sensors, they share the benefits of being both impact and abrasion resilient and having a case machined from a single-piece of stainless-steel – These are the sensors whose robustness is demonstrated by using them to hammer in nails.

The reliability of their performance and robustness enable you to minimise downtime and improve the OEE of Press-lines or verify assembly operations.

PRODUCT ADVANTAGES

️Reliable detection of double sheets

0.8 to 1.2mm thick sheets

✨Steel, Stainless-steel and aluminium sheets

Uniquely strong and reliable

IP68 / IP69K rated corrosion-resistant stainless-steel sensor

Virtually indestructible – Vibration and shock-resistant

⏱️ Pressure resistant up to 80 bar

Detects targets through up to 5mm thick stainless-steel

Highly reliable, cost-effective solution

FIND OUT MORE

PLUS Automation aims to help you #MAKESENSEOFSENSORS, helping solve applications, improve machine performance and reliability, and reduce costs using Contrinex’s exceptional choice of sensors. Find more information and read other application examples go to www.PLUSAx.co.uk

PLUS Automation aims to help you #MAKESENSEOFSENSORS, helping solve applications, improve machine performance and reliability, and reduce costs using Contrinex’s exceptional choice of sensors. Find more information and read other application examples go to www.PLUSAx.co.uk

Click to download a flyer to find out more about the sensors, or Click to download Contrinex’s Product Overview brochure