Hard turning has long since established itself as a leading manufacturing process in industries such as the bearing and automotive industries, tool and mold making, and tool manufacturing. In many machining applications, such as ball bearing production or tool technology, hard turning can save time and therefore money compared to grinding. When manufacturing complex workpieces in a single setup, the combination of hard turning and grinding operations in one machine leads to dimensional accuracy in the lower µ range while maintaining high process reliability.

For these very reasons, the precision tool manufacturer BIG KAISER has seen hard turning as a suitable complement to grinding for several years in order to meet the high quality standards of its products, which the name KAISER has stood for since its founding in 1948 and which the merger with the Japanese company BIG Daishowa in 2015 has not changed.

Today, on a 135,000 square meter production area, approximately 900 employees in four countries ensure that the modular tool systems – 20,000 standard products and 12,000 special parts – are manufactured with consistently high precision. BIG KAISER’s machine park at its founding location in Rümlang near Zurich has long featured a hard turning and grinding machine from a Swiss grinding machine manufacturer, although the focus is on grinding.

With the need to replace an aging lathe in 2014, the focus shifted to hard turning. Expanding machining capabilities was also on the wish list. “When purchasing a new machine, we always review our existing manufacturing processes,” explains BIG KAISER Production Manager Marcel Stettler, explaining the process for selecting a machine. “We are innovative with our products, and this is also reflected in our machining requirements.”

The list of machine manufacturers that produce high-precision hard turning machines is not very long. One of the leading companies in this field was the machine manufacturer Hardinge, which developed the SP51. This series is now part of the portfolio of the Swiss grinding group Kellenberger Switzerland AG. At an in-house exhibition of the then Swiss Hardinge representative PerfecBore, attended by Marcel Stettler and Marco Kotz, Head of Production at BIG KAISER, Managing Director Pierre Moser made contact with Product Manager Markus Günschmann. His presentation on hard turning on an SP51 machine had attracted the attention of the BIG Kaiser management.

After weighing up the various machine concepts from all suppliers, it was clear that the SP51 machines – and the SP51 in particular – were better suited to BIG KAISER’s specific requirements, particularly with regard to repeatability, than the machines from competitors. One selling point was the integration of the required circular milling into the machine. The additional challenge: batch sizes at BIG KAISER vary from one piece to several hundred parts. A diameter accuracy of 1 µm was also required. The German Hardinge branch gladly accepted the challenge of developing this process-oriented solution, focusing on the customer’s requirements. This was one of the reasons why BIG KAISER chose the SP51 in 2015.

BIG Kaiser Production Manager Marcel Stettler and Production Manager Marco Kotz are also

satisfied with the machine choice of the SP51 MSY…

…like Pierre Moser, Managing Director of the Swiss agency PerfecBore

Stability and accuracy

Due to their rigidity and stability, the CNC high-precision lathes are ideally suited for hard turning as well as for combined hard turning and grinding operations for the production of complex workpieces in a single setup. Measurement reports attest to the T series’ continuous machine accuracy of 3 µm, workpiece roundness of 0.25 µm (T42) and 0.70 µm (T65), repeatability (on all axes) of 0.76 µm and an achievable surface quality of better than Ra 0.15 µm or Rz1.

A 45° solid cast iron machine bed with Harcrete polymer concrete filling provides maximum vibration damping for higher surface qualities, longer service life, and reliable processes. The Collet Ready spindle concept allows for secure clamping of the workpiece directly in the spindle. The collet systems supported by the T-Series are not designed as adapter systems, as is usually the case. This requires a significantly shorter overhang and allows the workpiece to be machined as close as possible to the spindle bearings. The resulting maximum spindle rigidity is essential for achieving the highest precision.

The use of an independent Y-axis improves milling accuracy and enables high-precision tool center adjustment for hard turning. Powerful main spindles with speeds of 6,000/5,000/4,000 rpm and drive power of 11/15/26 kW form the basis for high-precision turning.

A BMT 55 tool turret with 12 stations, thanks to 1/2 indexing, allows for up to 24 stationary or 12 driven tools. The latter can be operated with a drive power of 5.5 kW, a torque of 42 Nm, and speeds of up to 8,000 revolutions per minute.

Process reliability and surface quality

“Confidence in the hard turning process was the most important thing for us at the beginning. That had to come first,” says Production Manager Marco Kotz. With the commissioning of the SP51, previously proven machining processes were redefined and streamlined, with the pleasing result of a reduction in throughput time. Within a short period of time, a large portion of the parts suitable for this machining process were already running on the new machine. “There are still parts and processes that are better suited to a grinding machine,” says Marco Kotz. “However, the results of hard turning are so high-quality that a grinding process is not always necessary.” Subsequently, the SP51 increasingly reached its capacity limits.

The expertise they had gained in hard turning and the resulting stability of the manufacturing process prompted Marcel Stettler and Marco Kotz to consider purchasing a second hard turning machine. This time, an integrated grinding unit, already planned for the first machine, would expand the machining capabilities. For this particular application, all potential manufacturers were initially considered. “Of all the machine manufacturers we contacted, however, only Hardinge guaranteed process reliability,” says Marcel Stettler. “That was a bold move and ultimately won us over.” The new SP51 MSY was ordered in December 2018 and delivered in the summer of 2019. A robot handling system for fully automated production was subsequently installed in October 2020.

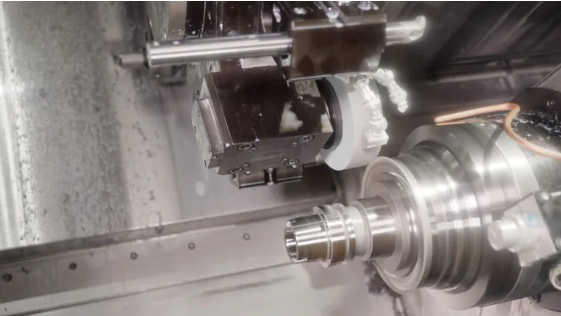

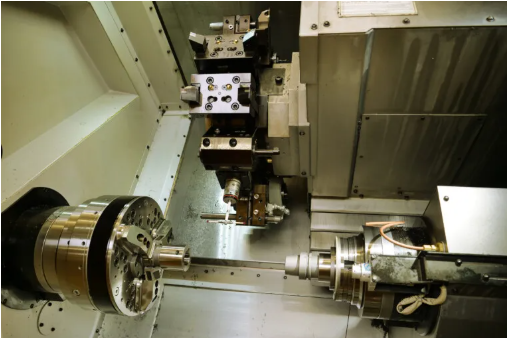

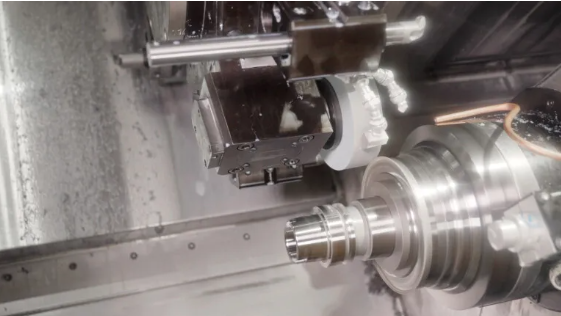

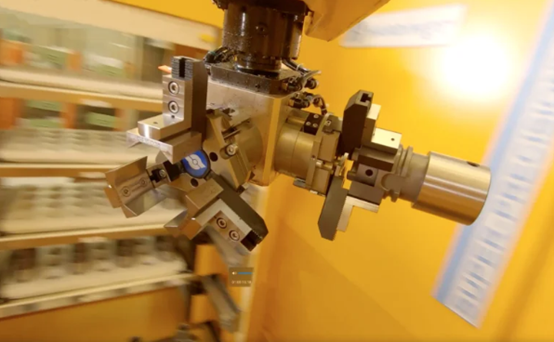

View into the machine room of the SP51 MSY main and counter spindle, tool turret with grinding unit

For the combined turning/milling and grinding operations required for the complete machining of HSK tool holders, the new SP51 MSY machine is equipped with a grinding unit with driven tools developed for BIG KAISER. This inclination is crucial for the finish grinding of tapers and shoulders. The SP51 MSY is ideally suited to the high demands placed on the workpiece’s precision regarding roundness and diameter tolerance on the taper, as well as concentricity between the HSK taper and the inner bore.

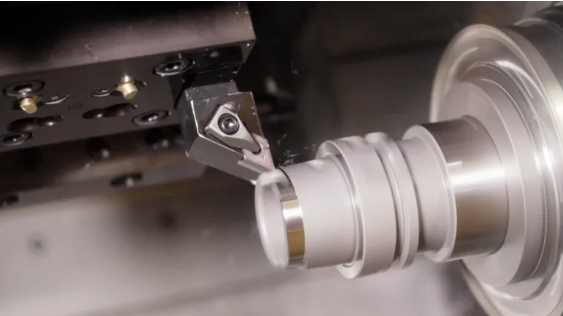

Dressing the grinding wheel for shoulder grinding

Hard turning of the outer and inner contours of the workpiece

“We are very satisfied with the overall performance of the SP51 MSY,” concludes Marco Kotz. “Although the machine can only process a limited range of materials, it does so all the more effectively.” Marcel Stettler adds: “We expect to see further innovative solutions in the future regarding the integration of grinding processes, for example, in the dressing cycles.”

The SP51 MSY is equipped with robot automation

The large work area is easily accessible