Digital Twin

Digital Twin – The Challenge

Creating a digital replica of a manufacturing process (often referred to as a digital twin) allows changes to be assessed, programmed and validated offline before needing to change the physical system. This can be invaluable in enabling flexible manufacturing solutions and critical in reducing time to bring production changes online. This is becoming increasingly important with ever-shortening new product introduction cycles and mass customisation trends in manufacturing.

However, differences between the virtual and physical environments due to the build-up of tolerance can seriously inhibit the effectiveness of a digital twin approach. For example, today it is typical for manual adjustments to be made to robot programs as part of a commissioning process. This manually corrects for differences in the robot position relative fixtures and the cell datum as well as correcting for the inherent inaccuracies and natural process variation with the robot. This diminishes much of the benefit gained by planning and assessing changes offline.

How IONA can help

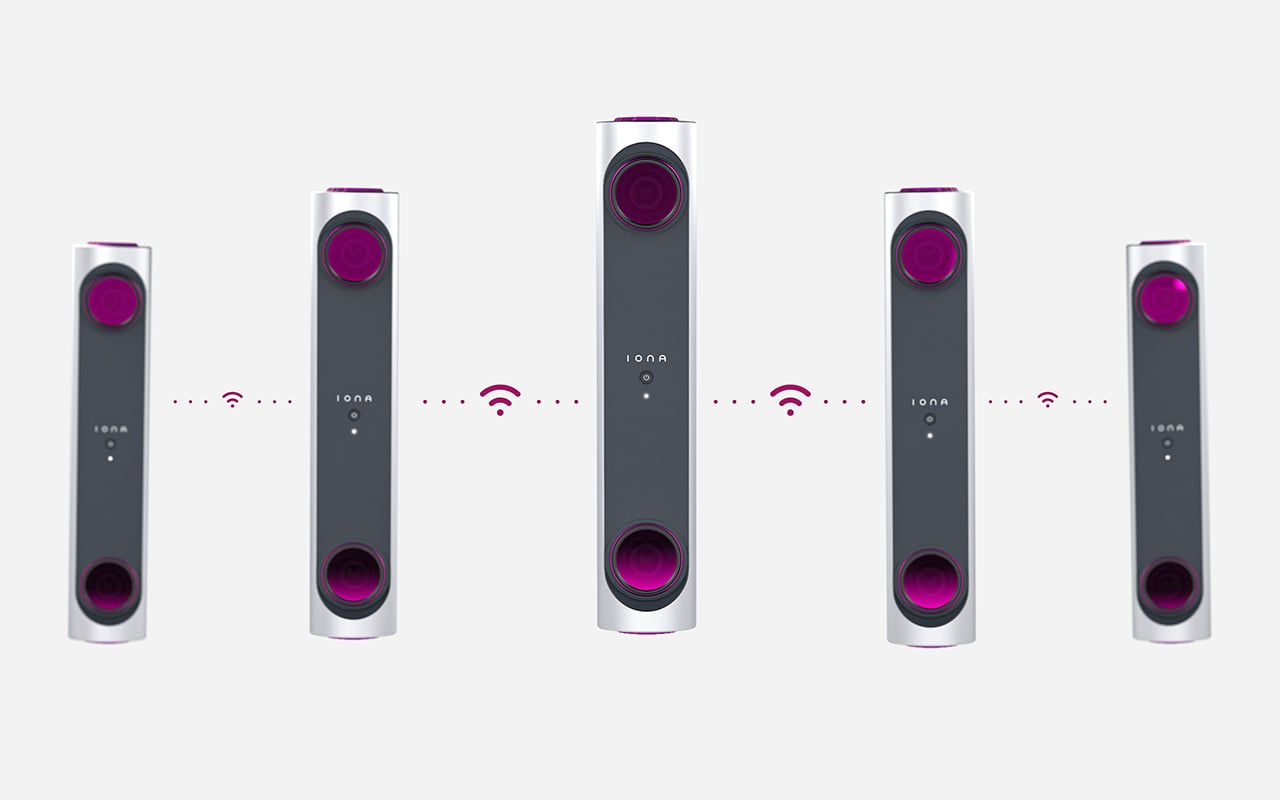

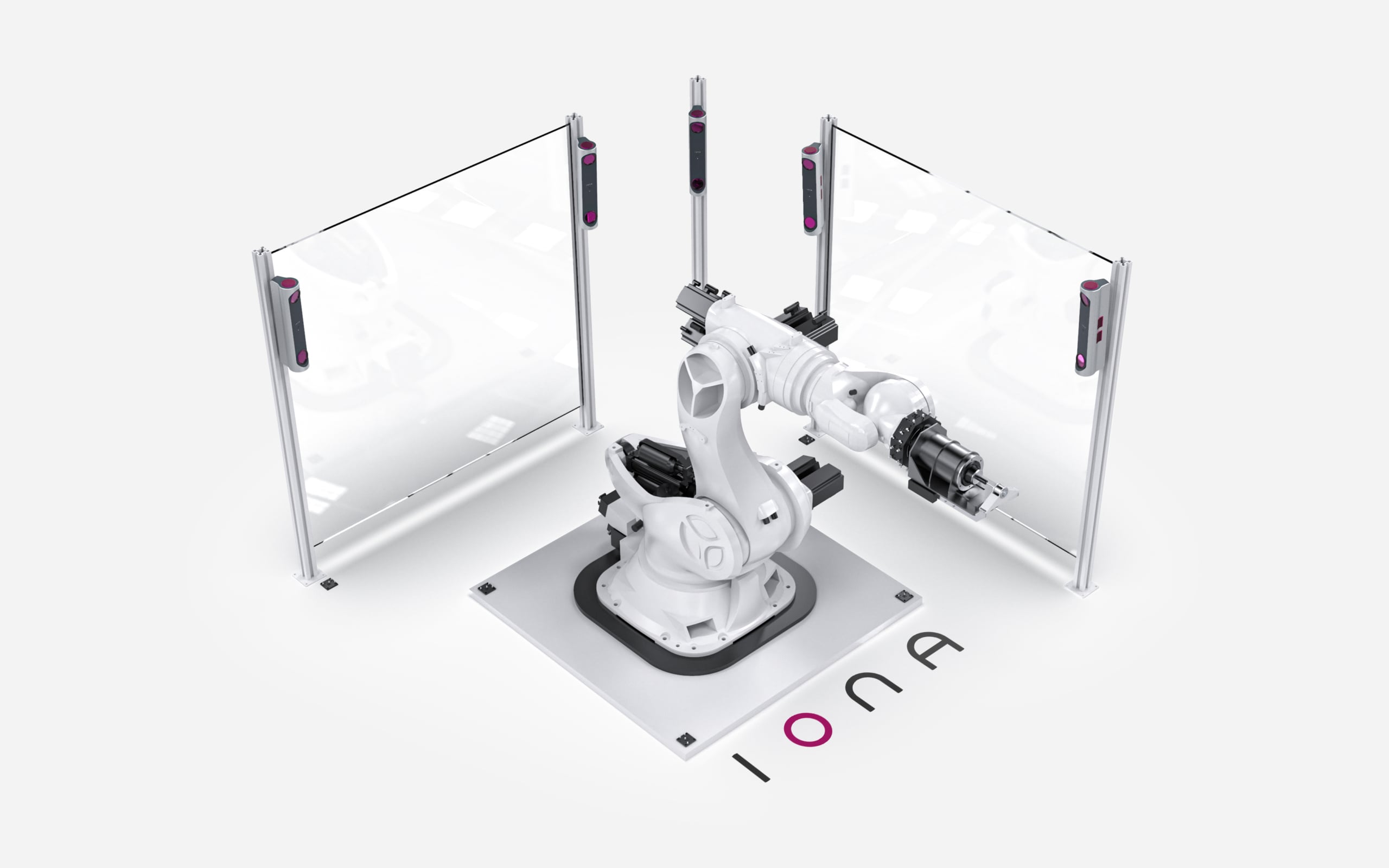

Using IONA, operators can validate the position of all elements of a manufacturing system including the static robot and fixture positions and the programmed movements of each of these elements. Updates can then be made to either the digital or physical system as appropriate. This can be done at the initial commissioning stage to ensure the as built set-up matches the digital layout. The physical setup can also be monitored in real time during operation to capture any changes that occur over time.

IONA System Outcomes

Having a simple and effective way of validating and updating the digital twin unlocks the full potential of simulating production systems in the virtual environment. Changes can be made and assessed offline, without disrupting current production. Greater confidence can be placed in the digital simulations knowing that the digital model accurately matches the real environment and that any changes can be accurately implemented. Making these changes without the need to manually intervene increases the system uptime and productivity and creates a truly flexible manufacturing system.

Discover how IONA can help your business!

Download the Brochure to find out more about IONA and the ways we can help your business