PTG Precision Engineers Ltd, a precision engineering specialist with over 40 years of experience serving the nuclear, aerospace, and energy sectors, has taken a significant step towards production automation with the installation of an SMEC NS2000 bar-fed turning centre supplied by Dugard. The investment represents the company’s first foray into automated machining and comes in response to a growing order book and persistent challenges in recruiting skilled machinists.

Company Background and Market Position

Since its establishment in 1979, PTG Precision Engineers has built a reputation for delivering high-precision components across demanding industrial sectors. The company serves a diverse customer base spanning the nuclear industry, oil and gas sector, OEM special-purpose machinery manufacturers, and the aerospace industry, where it specialises in producing jigs and fixtures rather than airborne components.

“PTG Precision Engineers has been operating for over 40 years now in various industries,” explains Jim Adkins, Production Manager at PTG. The company’s capabilities extend well beyond standard subcontract machining. PTG manufactures its own range of workholding products, including expanding mandrills in various sizes ranging from 12 to 400mm in diameter. This dual focus on both contract manufacturing and proprietary products requires considerable manufacturing flexibility and capacity.

The Capacity Challenge

Over the past 12 months, PTG has experienced a significant upturn in demand, creating operational pressures that existing production capacity struggled to accommodate. “Over the past 12 months, the order book at PTG has just been going up, and we haven’t been able to fulfil as many orders as we’d like,” Adkins explains. “We have struggled with getting skilled staff.”

This challenge is far from unique to PTG. The manufacturing sector across the UK continues to face a well-documented skills shortage, with experienced machinists in particularly short supply. The company needed a different approach. “One of the ways we looked to get around that was to get a semi-automated machine, and that’s when we called Paul from Dugard to see what they had to offer.”

Paul Roberts from Dugard says: “I’ve been working with PTG for quite a few years. Our recent meetings have all been about their fantastic order book, and how can we help them take that next step.”

This established relationship proved invaluable when PTG began exploring automation options. Roberts’ familiarity with the company’s work meant he could recommend a solution tailored to their specific requirements. When PTG mentioned their interest in a bar-fed lathe, Roberts put together a comprehensive package.

The SMEC Solution

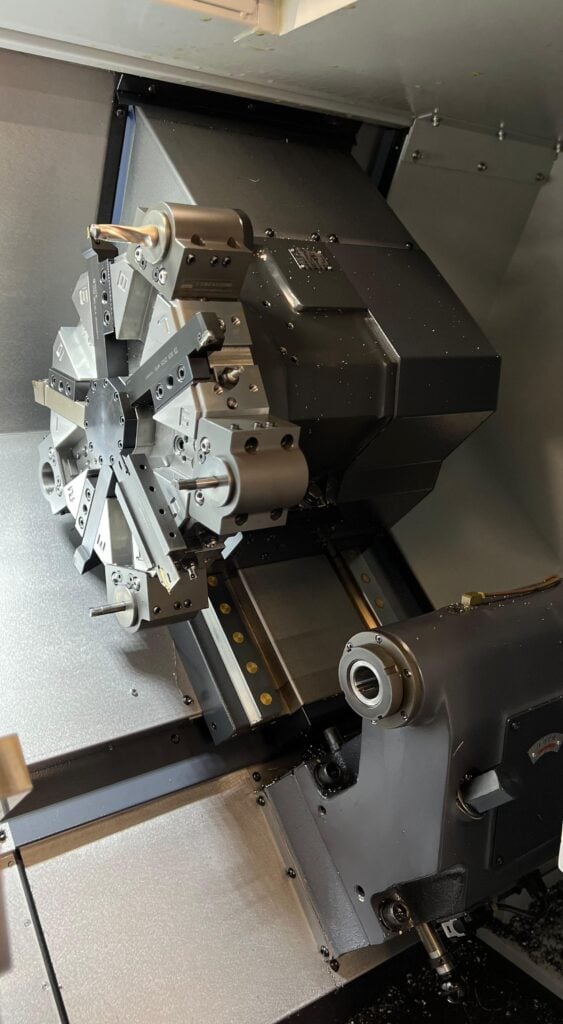

PTG selected the SMEC NS2000A, a bar fed turning centre that combines accessibility with precision. The NS2000A is equipped with a 6-inch chuck and offers a maximum turning diameter of 310mm, with a swing over bed of 565mm. The machine features a 6,000rpm spindle, driven by an 18.5kW spindle motor, proving perfect for the components PTG manufactures.

A key feature of the SMEC NS2000 is its LM (Linear Motion) roller guide system. Unlike traditional box ways, LM guides utilise precision-ground linear bearings that run on hardened steel rails, providing several critical advantages for precision work. The roller guide system reduces friction dramatically, enabling faster traverse rates whilst maintaining accuracy. The X-axis and Z-axis both achieve rapid traverse rates of 36m/min, which reduces non-cutting time and improves overall efficiency.

Highlighting the machine’s structural integrity, Roberts adds: “We chose SMEC because they’re looking for quality and repeatability, especially when they’re running automation. They need to know that the first part is the same as the 100, 200 or 300-off. The products they sell have to be the same every time. So the tolerance has to be right, every single time.”

The SMEC NS2000 has been integrated with an LNS bar feeder, representing a sophisticated addition to PTG’s production capabilities. The bar feeder’s magazine capacity enables extended unattended operation—critical for maximising productivity with PTG’s limited operator availability.

Operational Benefits

The transformation in production has been dramatic. Previously, PTG was processing batches of 25 expanding mandrills at a time on conventional equipment. With the SMEC NS2000 and LNS bar feeder combination, the company now runs batches of 350 off—a fourteen-fold increase in batch size that has fundamentally changed stock availability and production scheduling.

One of the key advantages of the installation has been its minimal impact on operator workload. The machine requires relatively little supervision once set up, allowing PTG’s skilled machinists to focus on other equipment. “This machine here just requires very little setup,” Adkins notes. “In the morning, we may spend an hour just setting the bar feeder, loading it up with bars, putting the programmes through again. Then the guys can go back and run the machines that they’re running on a daily basis, and just come back, taking the parts out of the part catcher every half an hour and just checking parts.”

This operating model maximises the productivity of PTG’s existing workforce. Skilled machinists aren’t tied to the bar-fed lathe throughout the day; instead, they can attend to other machines whilst the NS2000 runs largely unattended, only requiring periodic checking and part removal.

“The machine is generally used for the workholding product, the sleeves,” Adkins explains. “It’s all the same programmes we’re using for the machine, albeit just different sizes, so it makes sense to keep them programmed in the machine.”

Installation and Training

The implementation of PTG’s first automated machine tool required careful planning and training. Dugard’s support throughout this process proved exemplary, demonstrating the value of the long-standing relationship between the two companies.

“The install went really well,” says Adkins. “And then, obviously, the communication with Dugard to set up training, we can’t fault it. That went really well. The guys had two days of training, and they can operate it fully now.”

This rapid competency development is a testament to both the intuitive design of the SMEC NS2000 and to the quality of training provided by Dugard. Within just two days, PTG’s operators had gained sufficient confidence and capability to run the machine at full capacity—a crucial factor in ensuring the investment began delivering returns quickly.

Measurable Impact

After approximately three months of operation, the SMEC NS2000 has delivered tangible benefits to PTG. “It’s been on site now for a few months, and the impact to the customers is that it is literally rattling through the parts and reducing our lead times.”

For a company whose order book has been growing steadily, this capacity injection has been crucial to maintaining customer satisfaction and capturing opportunities that might otherwise have been declined. The ability to maintain stock levels of expanding mandrills—products that certain customers rely upon for immediate availability—has strengthened PTG’s competitive position in the workholding market.