In this Technical Corner video, Tony from Lang UK talks Joe Reynolds through the NEW #VastoClamp.

Like the Makro•4Grip clamping system, the Vasto•Clamp 6-Jaw Chuck has been engineered for clamping round parts as well. While Makro•4Grip is primarily applied for clamping round parts with the form-closure stamping technology, Vasto•Clamp uses a friction based clamping principle for clamping round material securely.

With its six top jaws Vasto•Clamp can be used for clamping raw parts with two different hardened gripping jaws or with soft jaws for components sensitive to deformation.

The manually actuated scroll chuck can be flexibly used as 2, 3- or 6- jaw chuck. The mounting and exchange of the jaws is done without the need for any tools by use of an innovative click mechanism, which provides a highly rigid and robust connection.

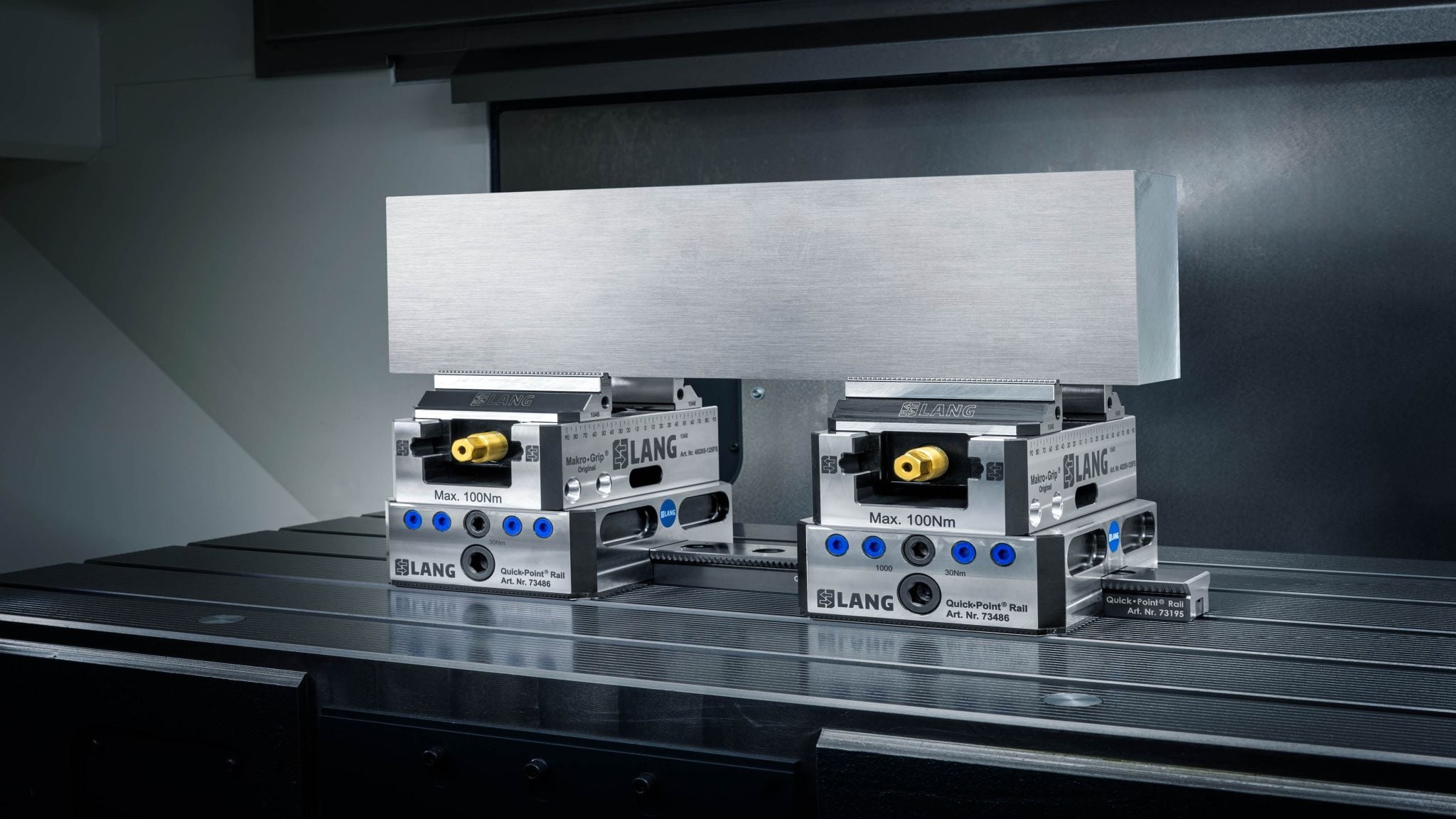

The Vasto•Clamp chuck is available with integrated zero-point studs for our Quick•Point® 96 zero-point clamping system, as well as integrated interface for the LANG RoboTrex automation