How the HALTER LoadAssistant CNC machine tending system can help your business

By Giovanni Albanese

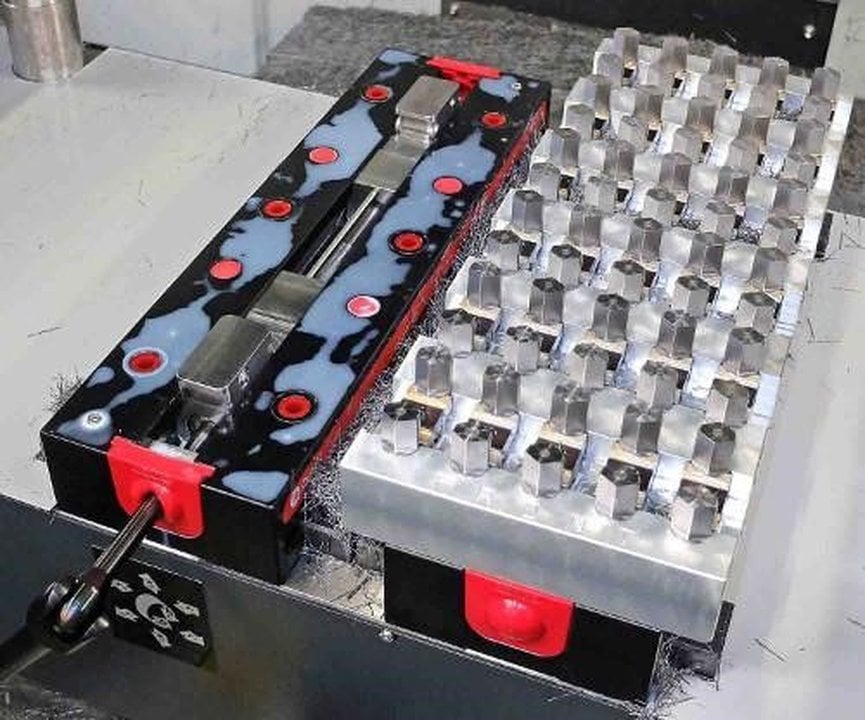

MTDCNC brings you an in-depth technical review of the Halter LoadAssitant supplied in the UK by 1st MTA. Giovanni Albanese interviews Marcus Hamlyn and Rik Peer from 1st MTA to talk about the automation solution and its importance in the UK and globally. With three different variants and three sizes of the portfolio, the Halter LoadAssistant offers Compact, Premium, or Big robotised CNC machine tending systems for turning, milling, or universal application. Each model comes with a Fanuc Robotic Arm weighing 12, 25/35, or 35/70 kg depending on the size. Halter’s automation solution offers simplicity of use and flexibility with high-mix low-volume work through smart control software. What other features make Halter’s solution unique? Two minutes to write a program, reduced robot idle time, workpiece specific grip plates, and flexibility for the operator in terms of planning. The Halter system can be moved from machine to machine, installed on different machines, or have the robot re-interfaced with a new machine. 1st MTA offer one-stop solutions with service and support for a variety of custom applications. With an ROI of 18 months to 2 years, there’s no reason why you can’t automate low-volume work! Contact 1st MTA for more on robotic loading solutions.