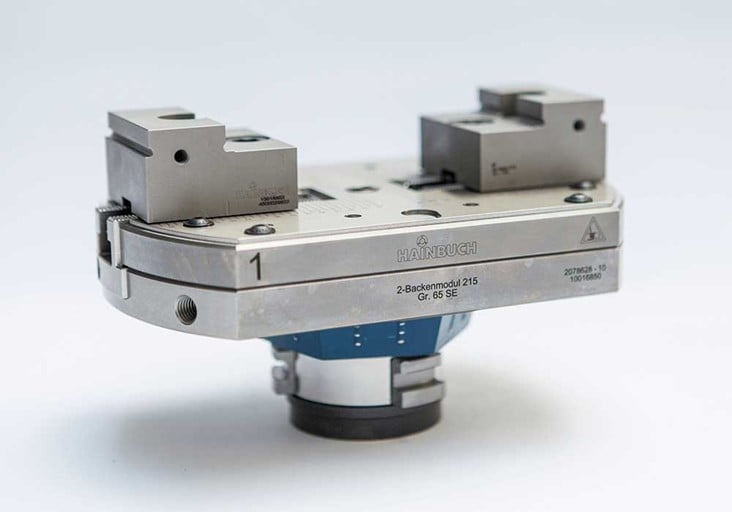

The long-established Leader/Hainbuch GmbH collaboration offers users globally recognized products and the new 2-Jaw Module is no exception. Maximum flexibility for machining a wide range of parts and small quantities is no longer just wishful thinking: with the HAINBUCH Modular System, it becomes a reality. Always looking for new ways to improve, HAINBUCH constantly adds to its modular system so that users can find the optimum solution for every clamping situation. However, one thing was still missing: an adaptation for clamping cubic parts. This paved the way for the 2-jaw module.

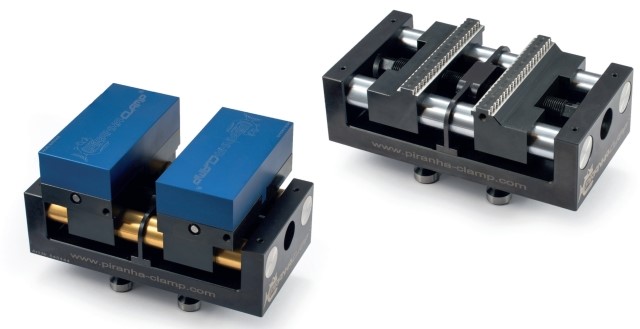

Round workpieces are clamped externally with classic clamping heads, but when these reach their limit, the 3-jaw module is used as a larger diameter of the workpiece needs to be clamped. For cubic parts, the 2-jaw module is used for centric clamping in machining centres and milling machines. The basic unit into which the jaw module is inserted is a Hainbuch chuck or vice. Modules can be exchanged without changing the clamping device and, thanks to the integrated Centrex quick-change interface, no alignment is needed.