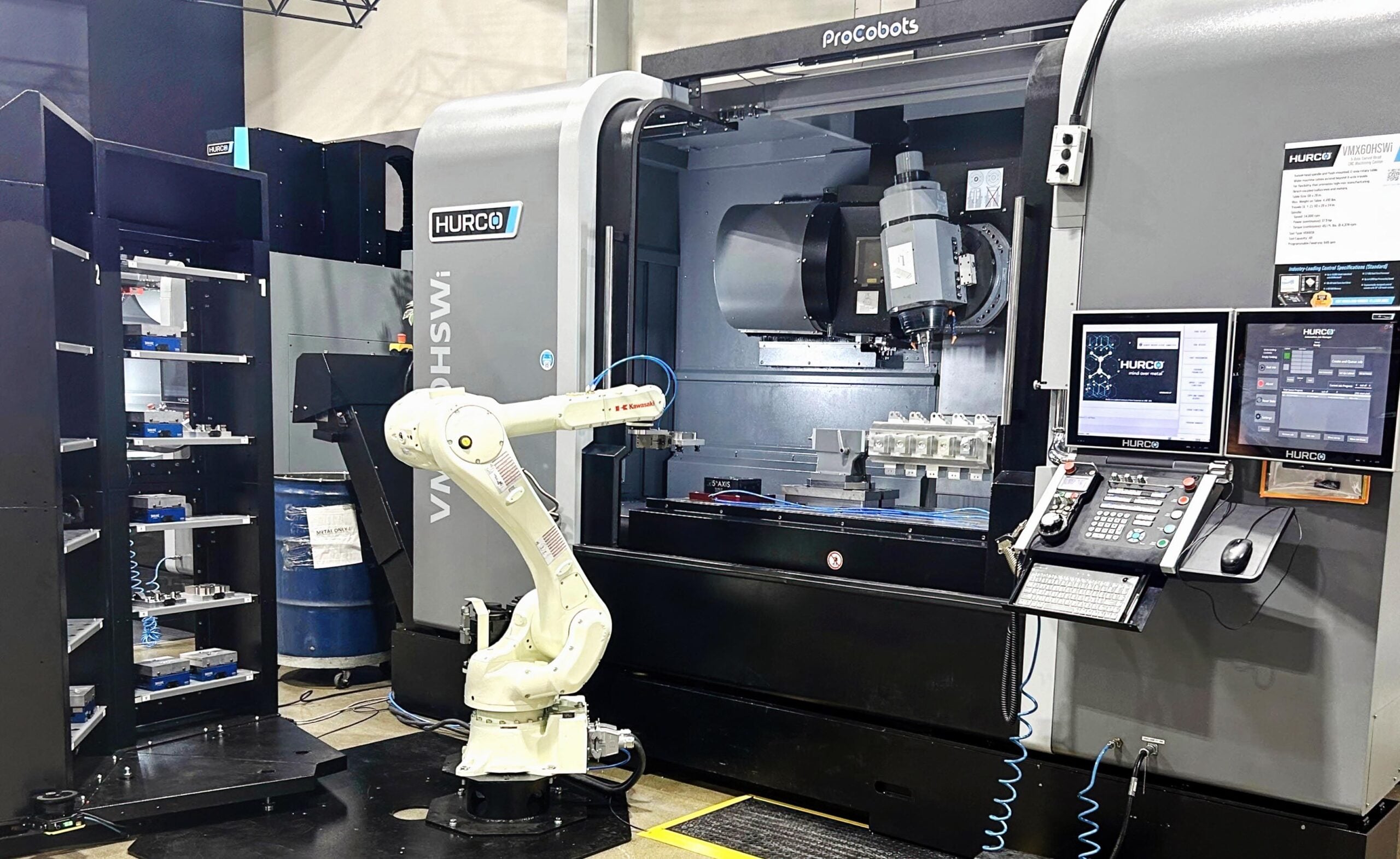

Terry Benfield, owner of TPB Precision Engineering (www.tpbprecision.co.uk) in Abingdon, Oxfordshire, has more than 25 years’ experience working in subcontract machining for a broad range of customers including in the medical industry, the scientific sector and motorsport. Once an applications engineer at Hurco, he chose two of their machines, a VM20i 3-axis machining centre and a TM8i lathe, when he started his own company in 2018.

Growth has been steady and additional milling and turning capacity was needed to meet demand from local customers. That requirement coincided with High Wycombe-based Hurco (www.hurco.co.uk) looking for companies to put its new range of driven-tool lathes through its paces. Mr Benfield’s previous experience working for the company made him an ideal candidate.

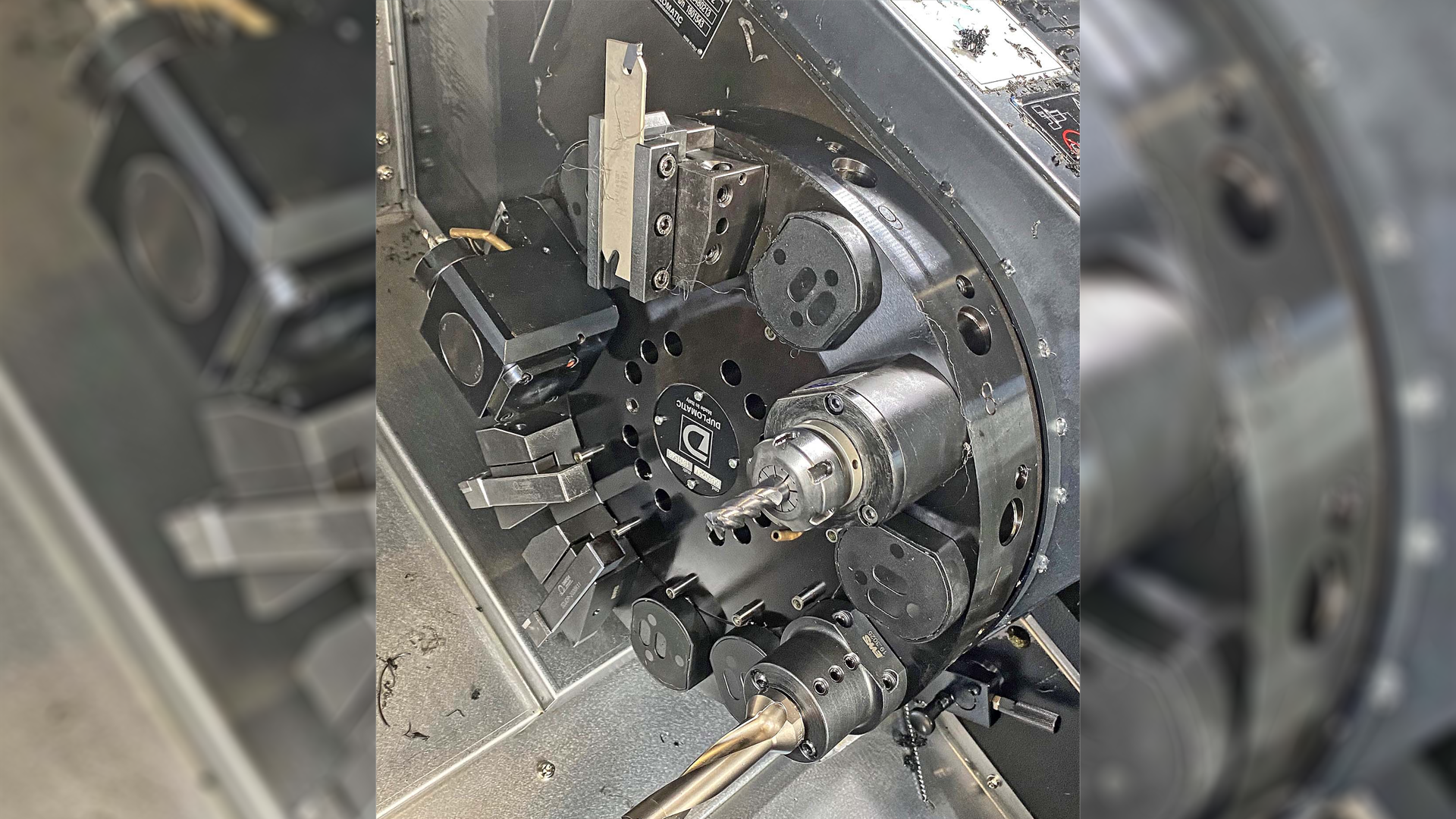

The TM8Mi turning centre has been fully redesigned compared to the previous model in terms of both machine and control. In addition to mechanical enhancements such as a more compact footprint and larger spindle bore to take 52 mm diameter bar, the lathe control has been improved to encompass features that are widely appreciated on the company’s proprietary WinMax conversational CNC software driving its machining centres. Concurrent programming, error checking and estimated run time have been incorporated, while processing speeds have also been improved and the graphics enhanced.

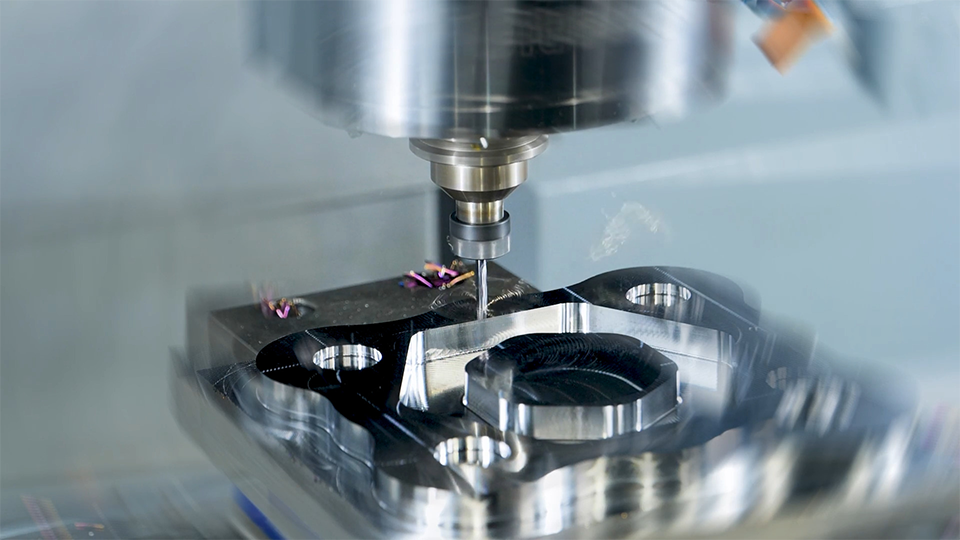

Mr Benfield commented, “Programming of the milling operations on the lathe are the same as rotary programming for the mill. It’s extremely easy to use.

“Due to space being limited within our workshop, we use a bar puller rather than a barfeed. It is perfect for us, as a lot of batches are quite small, often in the order of 50-off or less.”

For a business such as TPB, continuous, consistent accuracy of machining to within microns is essential. Even tough materials such as D2 tool steel are processed without difficulty or vibration. Mr Benfield describes the surface finish achieved as “always excellent”.

He added that owning the new TM8Mi is like having two machines. The ability to carry out off-centre drilling and milling operations on a shaft mean that complete components can often be finished in one hit, allowing him to offer more competitive prices by getting parts off in a single handling.

Based on his experience so far, it is probable that Mr Benfield will be working closely with Hurco again in the future. Some of his recommendations for programming enhancements and ease of use have already been taken on board by Hurco software engineers at the group’s headquarters in Indianapolis. As the Hurco range of turning centres grows, it is likely that further feedback from businesses such as TPB will prove essential.