Best practice advice is to routinely check your Coordinate Measurement Machines performance during the equipment's usage between annual service and calibrations.

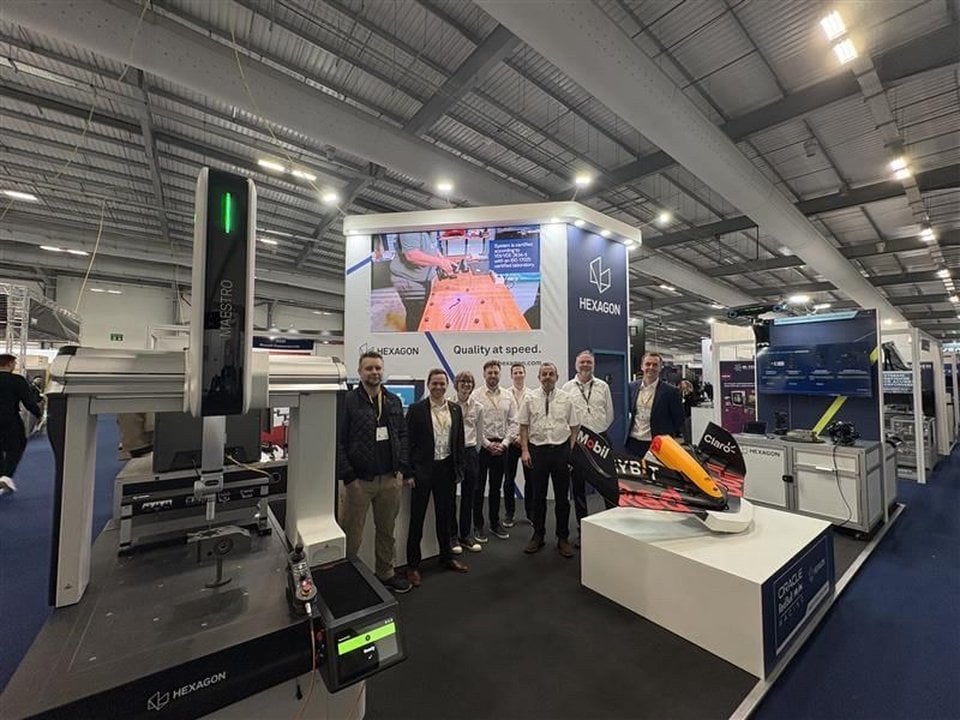

With that in mind MTDCNC went to the launch of the new Swift Check Artefact from Hexagon Manufacturing Intelligence.

The all new artefact based checking device for your CMM from Hexagon MI in the UK is a fully packaged solution; it comes with hardware; which includes the artefact, a ring gauge, length bar and calibration sphere, and with prewritten program routines in PCDMIS and Quindos, together with a support package where needed.

We met Aftermarket and Operations Director Mark Wilding who explained that the coordinate measurement artefact and the related programs are “designed to allow you the engineer to verify the machines integrity between annual service and calibration to make sure that you have the confidence that your CMM is still staying within tolerance.

If you have any changes within the environment such as loss of control of the room temperature or collisions on the machine” he said, “you very can quickly grab the artefact and reintroduce it, run the routines and get the reports to make sure the machine hasn’t been affected”

At competitive entry price of £3,972 and the fact that this artefact can be used on any coordinate measuring machine they recommend you grab one today to give you peace of mind between annual OEM service and calibration of you CMM.