XYZ Machine Tools unveils ground-breaking machines at MACH 2022

XYZ Machine Tools range of machines offers customers a natural route of progression from manual through to multi-axis machining and turning centres. That progression will be further enhanced with the arrival of two brand new and innovative groups of machining centres. The XYZ TMC (Toolroom Machining Centre) series and RMX 2-OP will enhance XYZ Machine Tools’ position as an innovator and driver of machining efficiency. The company will unveil both of these new machines on stand 17-200 at MACH 2022.

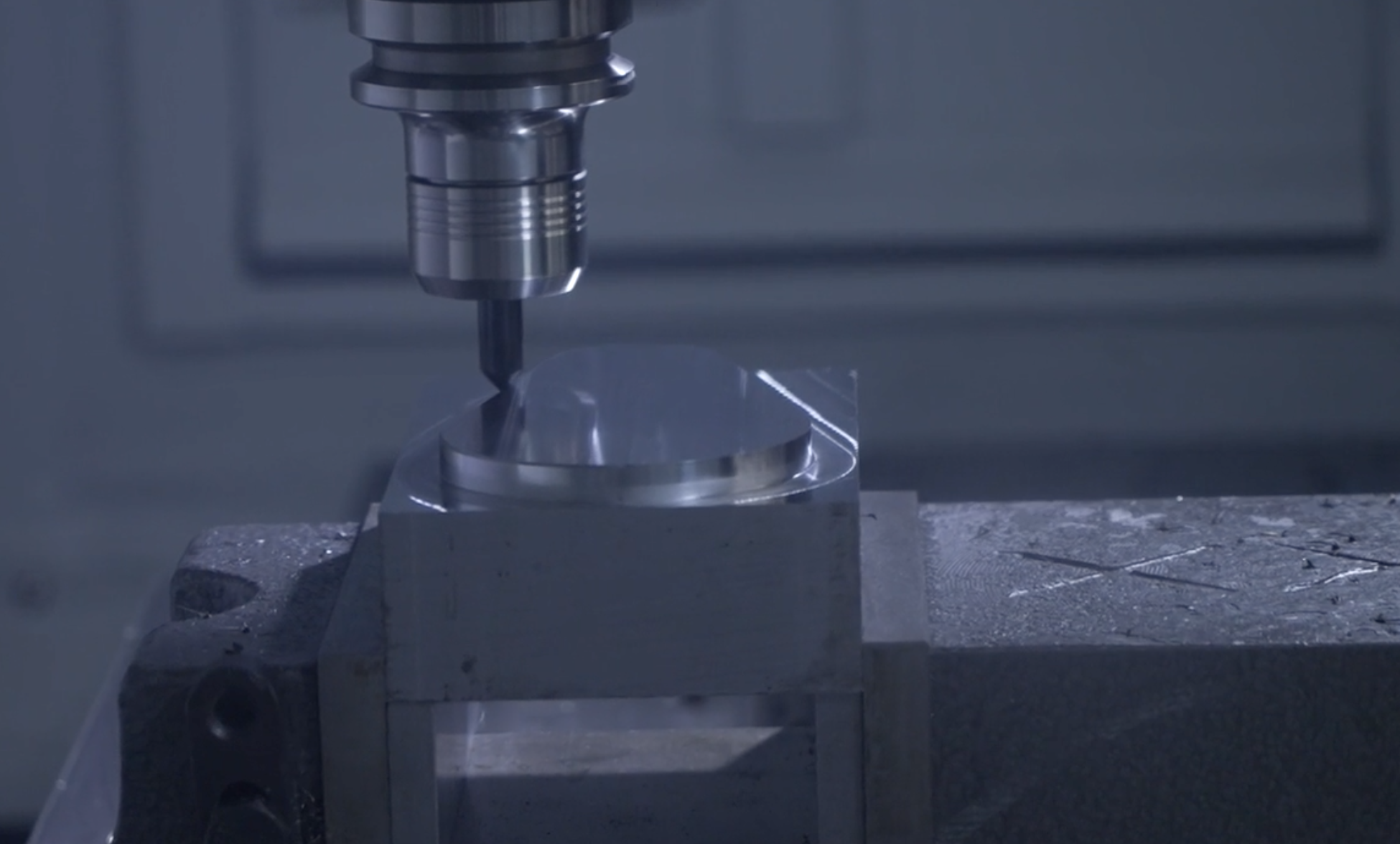

The four machines in the XYZ TMC range are fully equipped three-axis machining centres based on the already popular linear rail vertical machining centres from XYZ Machine Tools, and are available as 500, 750, 1000 and 1600 variants, with the number referencing the machine’s X-axis travel. Central to the development of the TMC series is the use of the ProtoTRAK RMX control system, a system that is already operating across many toolroom and low-volume manufacturing environments. With its touchscreen interface giving access to many easy-to-use programming tools the latest ProtoTRAK control builds on its existing advantage for low to medium production. This advantage is now extended by applying it to a machining centre platform for when those needing to expand on one-off, low-volume prototyping need to increase volumes, but retaining the existing familiarity of the ProtoTRAK system.

Equipped with fully enclosed guarding, 20 position toolchanger (12 position on the XYZ 500 TMC) all models have a 20 hp (15 kW) spindle power with 8000 revs/min (12,000 revs/min available as an option on some machines), the TMC series will take toolroom machining to the next level with medium to large batch work well within its capabilities. The use of the ProtoTRAK control brings many advantages which will be appreciated by current users, such as the TRAKing® feature, which uses handwheel movement to prove the program. The faster you wind the faster it machines. Stop or reverse the handwheel and the machine does the same. Again, for those familiar with XYZ Machine Tools’ ProtoTRAK bed mills the TMC series machines can be fitted with optional electronic handwheels in all axes. With this option users can work the machine as if it were a bed mill, using the DRO facility for manual machining, while having the security of the fully enclosed guarding to keep swarf and coolant within the machining environment.

The second new machining centre the XYZ 2-OP machine is brought fully up to date with the latest RMX ProtoTRAK control. With a footprint of just 775mm x 1,380mm and the ability to relocate it to anywhere in the machine shop that it is needed to relieve pressure on other machines by carrying out second operation work, the RMX 2-OP is a highly versatile and flexible machine tool. With axis travels of 355 mm x 305 mm x 455 mm (xyz) and a table load of up to 250 kg and a 3 hp (2.25 kW) 10000 revs/min spindle the RMX 2-OP is ideal for those secondary operations of face milling, drilling and tapping. While the XYZ RMX 2-OP may be compact it weighs in at 1100 kg and the bridge-type construction along with linear rails and pre-loaded ball screws in all axes ensure a rigid machining platform.

The use of the RMX ProtoTRAK control further simplifies programming to gain maximum efficiency, with users having the option of programming at the machine using the tried and tested conversational programming software or using offline programming making use of ProtoTRAK’s G-code compatibility for more complex 3D components. While retaining many features that made ProtoTRAK the success it is, the latest RX version adds even more features, such as Enhanced ProtoTRAK Assistance (EPA), giving instant access to in-depth help at any point in the programming/operating procedure. A feature that addresses the change in skill sets that businesses are facing, where traditional mechanical skills with limited technology knowledge are being reversed, with the next generation having possibly lower levels of engineering/metalcutting experience, but higher acceptance of computer technology.

Auto Geometry Engine (AGE) is also a feature of the ProtoTRAK RMX control. AGE is effectively a CAD capability within the control allowing users to overcome issues when data is lacking from drawings by automatically calculating missing dimensions during programming. Touchscreen capability takes AGE to a new level, with the new Tap to Guess feature. With the part shown on-screen, simply tapping the screen where the intersection or tangent point is unknown, the AGE software calculates the dimension data. AGE can be used in both profiles and pockets and is capable of machining pockets with an unlimited number of islands located inside their boundaries.

Other new features are Adaptive Toolpath, which can drastically reduce cycle times on complex milling cycles, a feature more commonly found on high-end CAD/CAM systems. The ‘look’ feature now runs alongside the program inputs for program verification along with live updating of program events, it will also show a conventional toolpath and give the user estimated cycle times to ensure the most efficient method has been selected. For the ultimate program check a solid 3D rendered image can be shown using the verify feature.

The control also comes with the option of adding a DXF Converter which benefits from the touchscreen technology to deliver substantial advantages, as importing a DXF file is completely streamlined, eliminating the need for supplementary software and the requirement for a mouse to be connected. A further development is the ability to mix DXF and manual programming during program generation, giving the user total flexibility, all of which is facilitated by the touchscreen. The RMX ProtoTRAK control is also capable of handling Parasolid 3D model files, making the machining of more complex 3-dimensional parts straightforward, more so with the use of the touchscreen to manipulate parts during programming.

“With close to 15,000 ProtoTRAK controlled mills and lathes installed in the UK extending the use of this versatile, flexible and productivity enhancing control will be a relatively straightforward step for many toolroom, low volume production environments,” says Nigel Atherton, Managing Director, XYZ Machine Tools. “Throughout the past 1-2 years we have continued to innovate and, the timing of MACH 2022 couldn’t be better as we can bring these new developments to a wider audience and demonstrate their capabilities, with visitors having the option of putting ProtoTRAK through its paces.”