Starrag, a leader in precision engineering, is making significant strides in reducing component costs for manufacturers. The company emphasizes a holistic approach, exploring potential savings at every stage of the production process. This initiative aims to enhance efficiency and identify areas for cost reduction, which is pivotal for maintaining competitive advantage in the manufacturing sector.

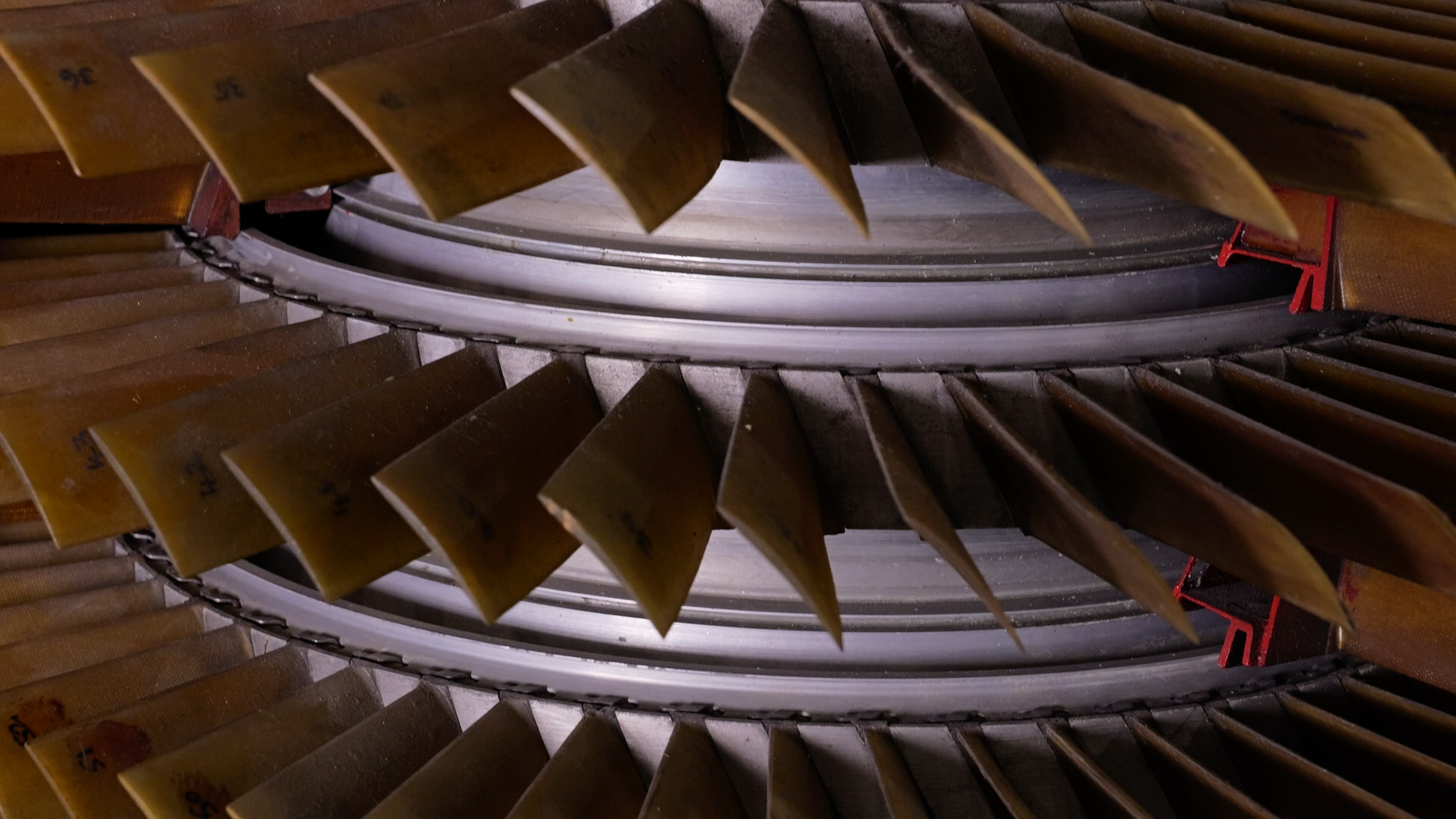

Starrag is known for its expertise in the aerospace industry, utilizing advanced technology to support the production of components such as blisks, impellers, and turbine blades. The company employs a variety of cutting tools, including Torus cutters, lollipop cutters, and a range of barrel and taper ball nose cutters. These tools are designed for precision and efficiency, addressing the complex demands of modern engineering tasks.

The company is focused on providing high-quality, precise tools that reduce wastage and optimize production lines. Starrag’s commitment to engineering excellence ensures that their clients receive solutions tailored to their specific needs, ultimately driving down costs and improving product quality.

Starrag’s innovations are crucial for industries that rely on high-precision components, particularly aerospace and energy sectors. By employing state-of-the-art equipment and methodologies, Starrag not only cuts costs but also sets new standards for precision and reliability in the manufacturing industry.

Founded in 1074, Starrag continues to be a key player in engineering precision tools that deliver what is truly valued by engineers and manufacturers alike.