Through collaborations with customers and their partners, Seco Tools monitors trends and identifies challenges, developing the knowledge needed to overcome the industry’s most complex problems.

Customers are placed at the heart of Seco’s research and development (R&D) and this has led to excellent results in terms of identifying and developing new products and solutions that can help change manufacturing around the world. “By proactively solving the problems customers have today, we are creating the solutions of the future. We are striving to acquire and develop knowledge and understanding,” says Roger Granström, Senior R&D Manager at Seco Tools.

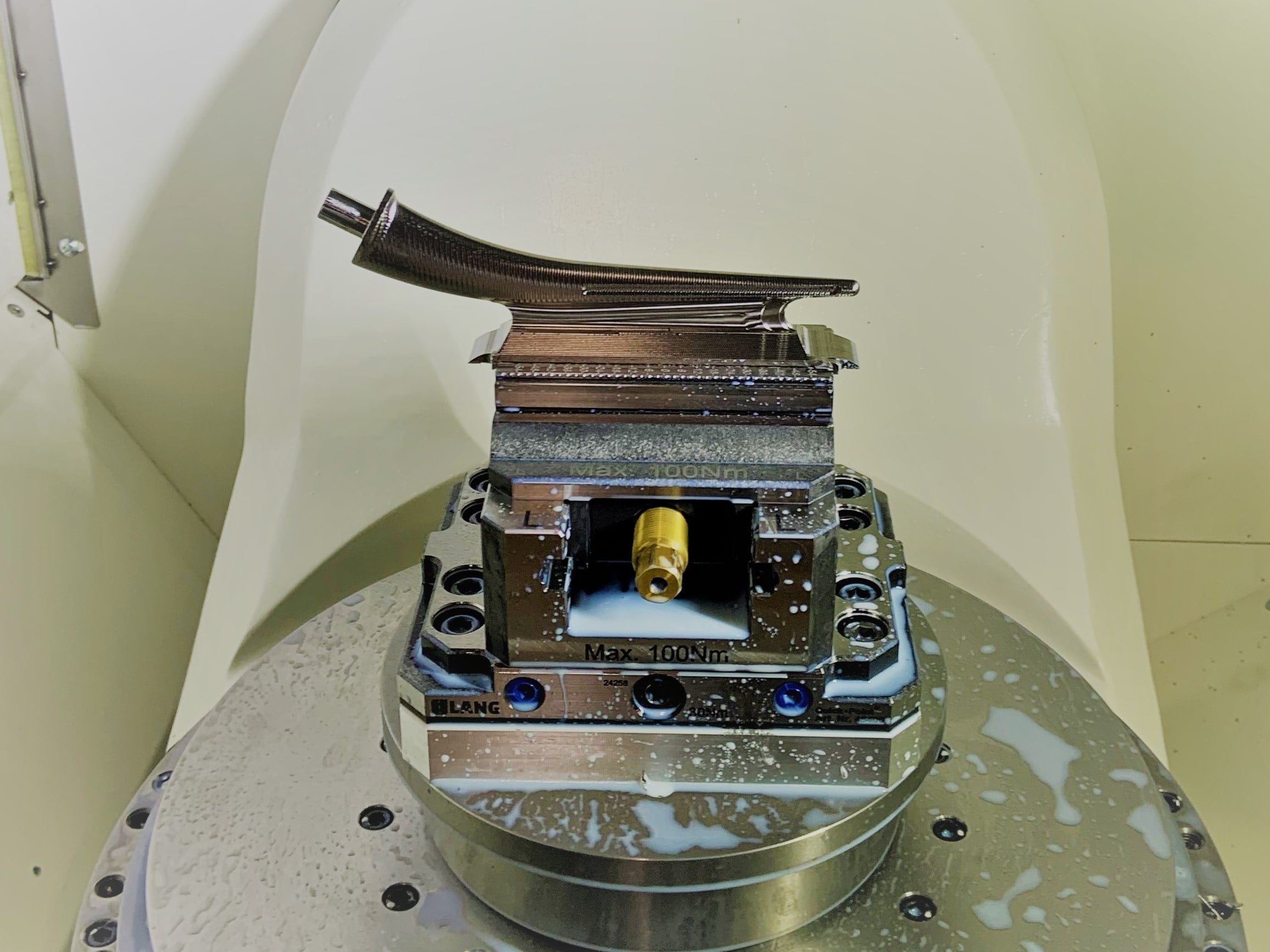

Granström points to a partnership with a major vehicle manufacturer as proof that the idea is working. “They had a project they didn’t want to talk about or share details about, a next-generation component platform. We started to consider the challenges of manufacturing and along the way we built a lot of mutual trust. This led top management to show great. interest in assisting the customer with a large automation project that will transform the manufacturing process, thereby exceeding our expectations, “says Roger Granström.

Such projects require sensitivity and trust. Customers must be prepared to provide information on potentially commercially sensitive practices and processes for technicians and support staff to study them in depth and develop new ideas. “It is a path of trust. Seco Tools is one of several tool suppliers on the market and we need to show our customers that we are worthy of this trust. We are trying to build a bridge between ourselves, the technical universities and our customers and the latter. They begin to understand that this is exactly what they need, “says Roger Granström.

The customers with whom Seco Tools collaborates are those considered technology leaders who drive development in their industry. The initiative is based on the principle of dialogue between Seco Tools and the customer. Once a problem of mutual interest has been identified, Seco Tools is committed to providing the customer with the resources necessary to analyze it and find possible solutions. “The issues raised can be very specific, from one customer to another and from one industry to another, but there are always things we know that can be applied elsewhere. We talk a lot about sustainability and energy efficiency and the new demands of daily operations. producers are constantly being put in place, “says Roger Granström. “Knowledge is always useful, regardless of where it comes from. We always have the ability to use the insights learned from these partnerships and projects to advance our development. We are less interested in the commercial aspect than the knowledge aspect, “he explains.

Building bridges

When it comes to joint operations, Seco Tools works together with several polytechnics in Sweden as well as leading European and American universities. “The goal is to build connections between ourselves, the school and our customers and industrialize new technologies as quickly as possible,” says Roger Granström. “We are getting closer to our customers and we want to be even closer. We work in a very competitive environment and collaboration with them is essential.”

The close relationship with customers will continue to be a fundamental part of Seco Tools’ research and development work in the future. “We are currently working with four different customers in different industry segments and are looking at three or four other potential future collaborations,” explains Roger Granström. “We are looking forward to sharing our vast experience with these customers and starting to collaborate. It is in our best interest to offer them maximum support in their transition to the next era of production.”