Manufacturing companies continually seek ways to reduce costs and improve efficiency. Sandvik Coromant, a leader in cutting tool solutions, highlights the significance of identifying hidden inefficiencies that may be quietly affecting profit margins within manufacturing processes.

In its latest insights, Sandvik Coromant emphasizes the importance of detecting and eliminating these inefficiencies to enhance operational productivity. The article explores common areas where resources are often wasted, including outdated equipment, ineffective supply chain management, and energy-intensive processes that do not align with current technological advancements.

Sandvik Coromant advises manufacturing companies to adopt a proactive approach by conducting thorough process audits. These audits can identify bottlenecks and streamline workflows, ultimately leading to significant cost savings. The company suggests implementing modernized machinery and exploring automated solutions to optimize production lines.

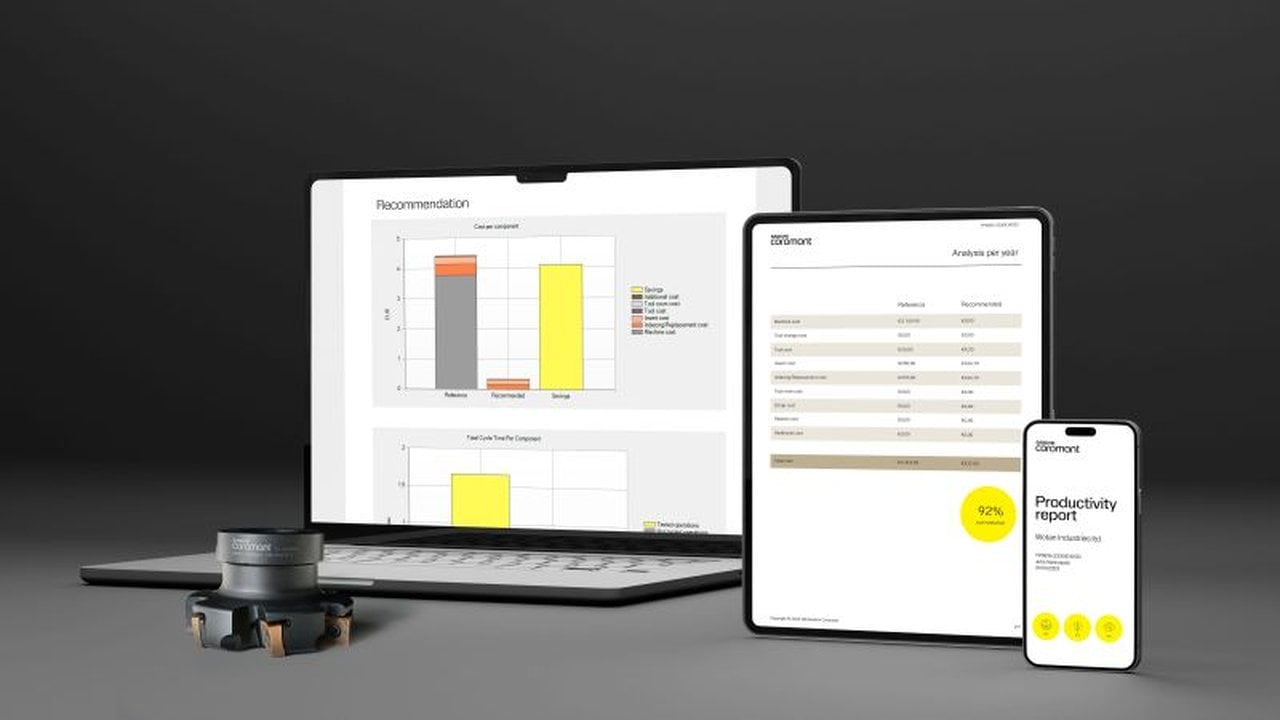

Furthermore, the strategic use of data analytics is advised to provide valuable insights into operations, helping businesses identify patterns and predict potential areas for improvement. This data-driven strategy can play a crucial role in minimizing downtime and ensuring the efficient use of resources.

Sandvik Coromant, known globally for its innovative tools and extensive industry expertise, continues to support manufacturing businesses seeking to enhance their operational efficiencies. By providing thought leadership, the company reinforces its commitment to driving industry standards forward.

Headquartered in Sweden, Sandvik Coromant remains at the forefront of helping manufacturers tackle economic challenges by promoting best practices and sustainable solutions.