In a significant development for the manufacturing sector, Sandvik Coromant has announced a collaboration with Hexagon AB to integrate tooling data directly into WORKNC, a leading CAM software. This strategic partnership aims to streamline CAM programming workflows, offering enhanced efficiency and precision for those involved in mould, die, and precision machining.

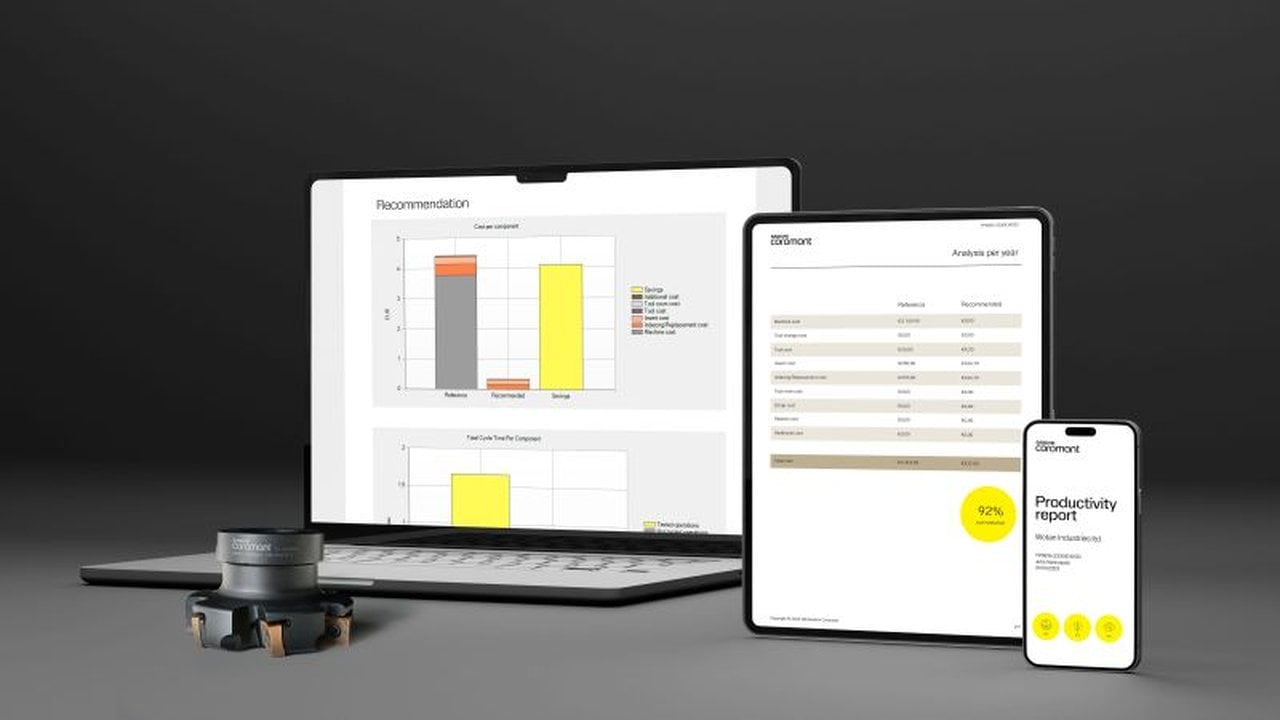

The integration allows CAM programmers to access Sandvik Coromant’s validated tooling data seamlessly within their CAM environment. This new capability supports tool selection, assembly building, and CAM preparation, thereby reducing manual input and fostering more consistent programming practices. By minimizing uncertainties and steps in the preparation process, manufacturers can now execute their first cuts with increased confidence.

The collaboration highlights the continuous advancement towards digital machining solutions. By reducing manual intervention, the integration ensures smoother operations and enhances overall productivity. This change, though subtle, propels the manufacturing industry forward by adopting more connected and reliable digital processes.

Sandvik Coromant, a global leader in cutting tools and tooling systems, continues to drive innovation with its focus on sustainability and productivity. The company is committed to providing comprehensive manufacturing solutions that meet the demands of modern production environments. Hexagon AB, known for its cutting-edge software solutions, partners in this effort by enhancing WORKNC with reliable tooling data integration.

This development demonstrates the ongoing evolution in CAM software capabilities, offering manufacturers tangible benefits in ensuring greater efficiency and accuracy in their machining operations.

View more news from Sandvik Coromant