JOTA ADVANCED ENGINEERING’S REMARKABLE GROWTH DRIVEN BY PSL DATATRACK AND AVISO CONSULTANCY

From humble beginnings, with four CNC machines and a handful of spreadsheets, Jota Advanced Engineering Limited has transformed into a high-performing precision engineering business with 17 CNC machines and ambitions for even greater growth.

Central to this remarkable journey has been the partnership with PSL Datatrack, providers of modular production control software for subcontract precision engineers, and AvISO Consultancy Ltd, specialists in ISO 9001 implementation and compliance. Together, these collaborations have helped Jota streamline operations, embed a data-driven culture and achieve ISO 9001 certification – all while retaining the agility and precision that has long defined its motorsport heritage.

Ryan Goodger, Managing Director of Jota, recalls those early days: “We were new to the sector, but we approached every project with the same rigor as our race team: fast turnaround, attention to detail and uncompromising quality. That ethos has carried through to every part of our growth.” Combined with the operational discipline brought by PSL Datatrack’s production management software, this mindset has been central to the company’s success.

Before adopting a centralised system, Jota managed quoting, order processing and production scheduling using spreadsheets and basic document management. While the team delivered high-quality results, the limits of manual systems quickly became apparent as the business began to grow: a lack of visibility across operations, duplicated data and the risk of human error made it increasingly difficult to scale efficiently.

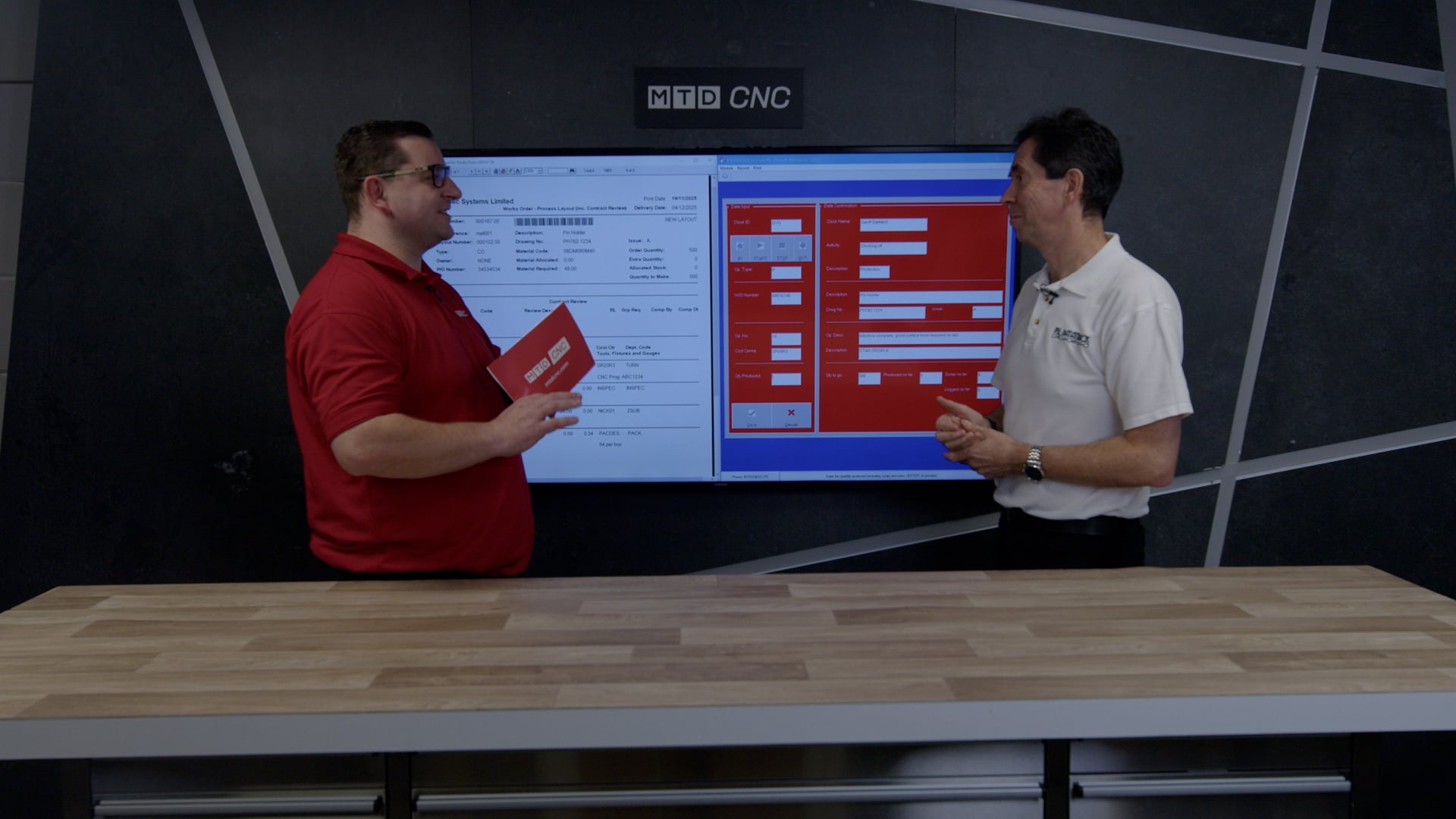

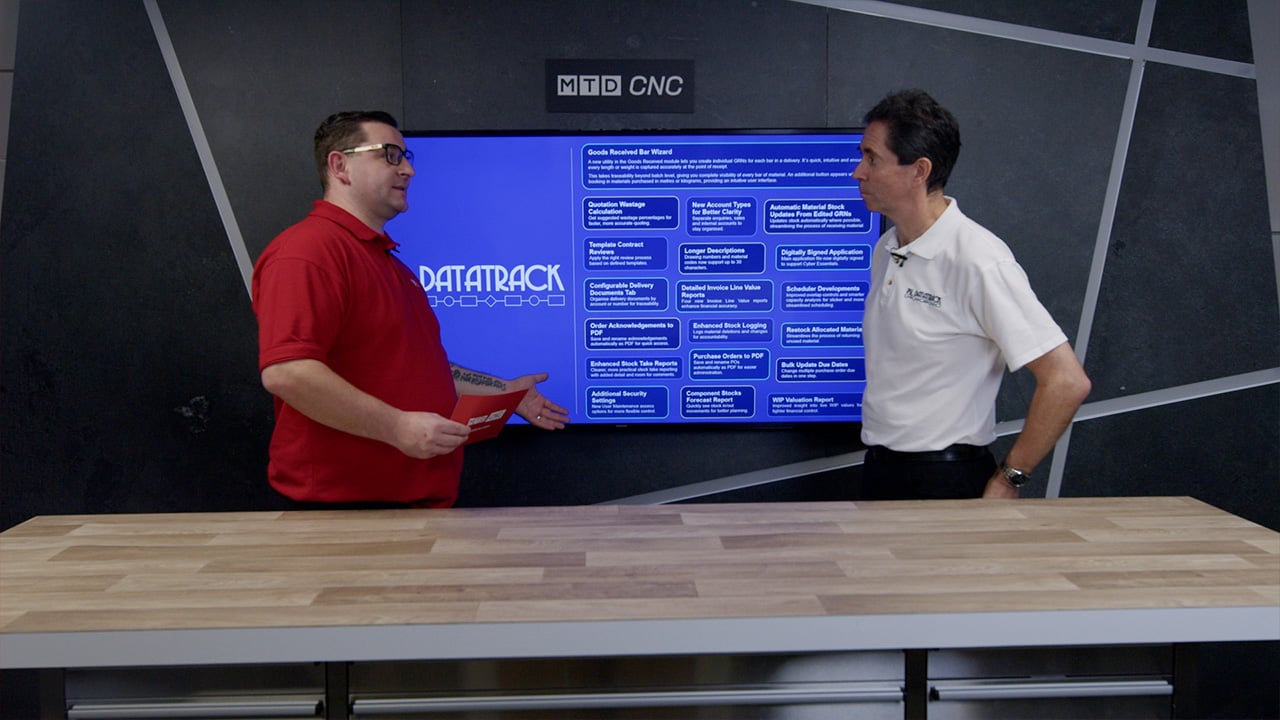

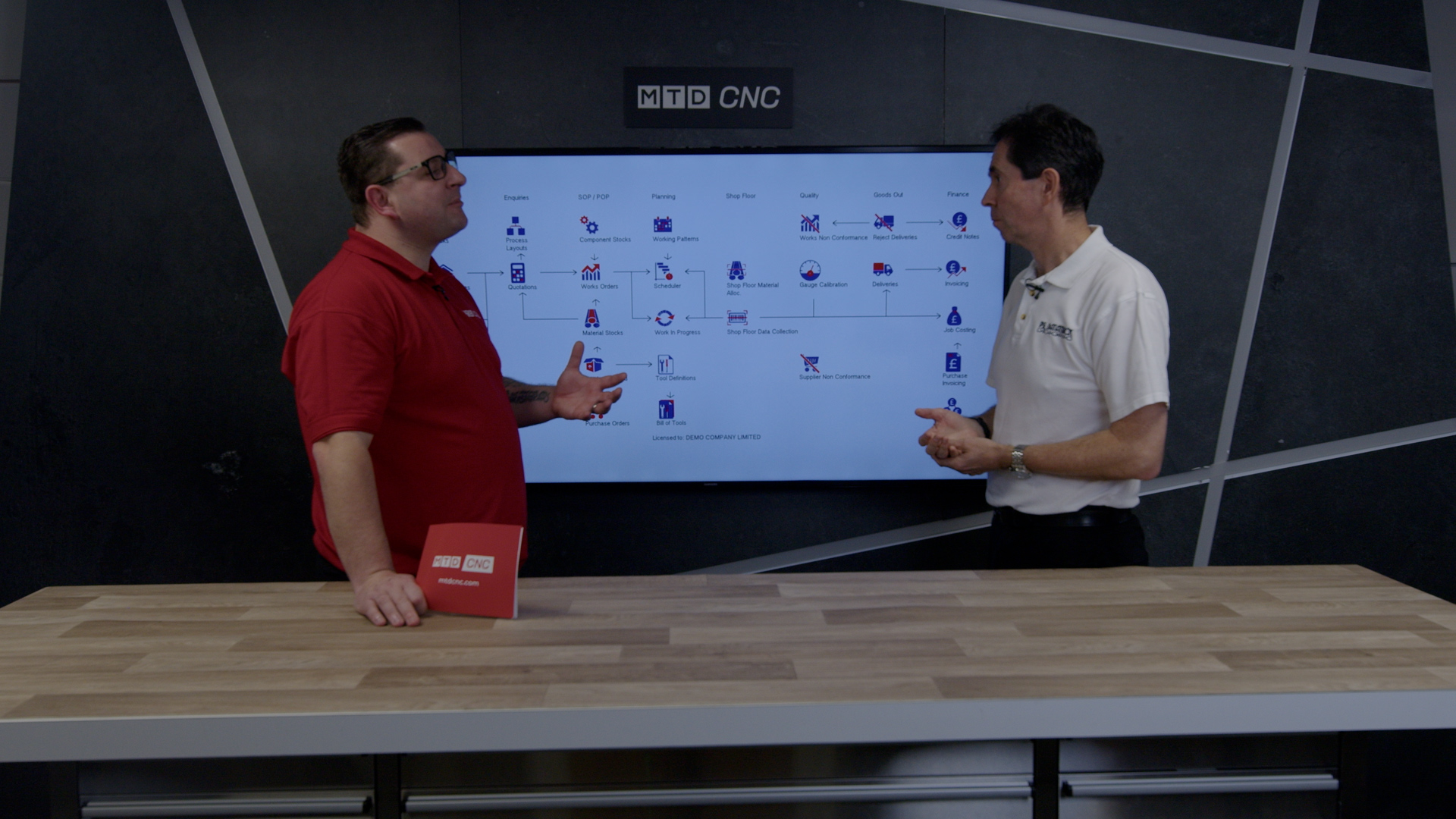

In 2016, following a meeting at MACH and an onsite demo, Jota adopted PSL Datatrack. Geoff Gartland, Managing Director of PSL Datatrack, explains: “They were doing a great job, but there was only so far they could go with manual systems. PSL Datatrack gave them real-time control over every aspect of production – from quoting and works order management to CNC shop scheduling and shop floor data collection. That’s when chapter two of Jota’s growth really began.”

The modular nature of PSL Datatrack allowed Jota to start with essential functionality, such as quoting, job tracking and inventory management, while adding more advanced modules over time. Customised reports gave management clear, actionable insights, and the introduction of Status Boards – live visual displays inspired by airport arrival and departure boards – ensured every team member could see work in progress at a glance.

Ryan explains: “Status Boards bring your data to life. Everyone knows what’s expected and it turns production into a team activity, rather than leaving information in one person’s head or buried in spreadsheets.” Geoff adds, reinforcing this approach: “Status Boards foster accountability across the team – they can see why they’re doing something and how it contributes to the business.”

Shop floor data collection software has allowed Jota to record cycle times, quantities produced and any scrap or corrective actions. Geoff notes: “If something is printed, it’s already out of date. Live data gives you the insight to make real-time decisions and improve efficiency. If you can’t measure and improve something, why are you doing it?” The data-driven approach has enabled continuous improvement across all areas of the business, from manufacturing process automation to works order management and gap analysis via dual direction scheduling.

Alongside operational enhancements, Jota recognised that becoming certified to ISO 9001 standards would support sustainable growth. AvISO Consultancy has worked with the company since 2016, initially helping transition to ISO 9001:2015 and subsequently maintaining and optimising the management system.

AvISO Consultancy worked alongside Jota’s leadership to ensure that ISO 9001 was embedded in a way that supported the company’s ambitions, not just compliance. AvISO’s tailored approach meant the management system became a practical tool for improvement, not a bureaucratic hurdle.

With AvISO’s ongoing support through regular reviews, internal audits and improvement workshops, Jota continues to refine its processes so that quality and efficiency keep pace with growth.

Paul Stevens, Managing Director of AvISO, explains: “ISO 9001 helps prove credibility to customers, streamlines tendering and embeds a culture of accountability and traceability. For a growing business like Jota, it’s not just about compliance – it’s a tool to continually improve processes and make audits a positive, evidence-based exercise.”

The partnership between PSL Datatrack and AvISO means Jota benefits from both real time operational data and expert guidance on using that data to drive continual improvement.

“The system provides the evidence you need to show that you’re doing what you say you’re doing. PSL Datatrack feeds into the management system, giving Jota confidence that every project is handled consistently, from arrival to delivery. That data supports continual improvement and helps us guide them as they grow,” continues Paul.

As a result, Jota’s growth since 2016 has been astronomical. Moving from a 3,000 sq. ft. facility with four machines to a 15,000 sq. ft. site housing 17 CNC machines, the company has been able to increase capacity, improve quality and expand into new sectors such as aerospace while continuing to serve its motorsport and automotive clients.

“The operational benefits of PSL Datatrack are clear,” Ryan comments. “The Quotations module allows for fast and accurate estimates, while works order management and the Sequential Scheduler module optimise capacity and workflow. Integrated document management software ensures every procedure and drawing is easily accessible and Shop Floor Data Capture (SFDC) provides instant insight into performance, helping us to improve.”

The system has also enhanced the company’s external credibility. Paul adds: “For companies like Jota, ISO 9001 certification shows credibility to the marketplace. Customers can see that processes are monitored and managed effectively. Combining PSL Datatrack with a robust quality management system ensures that evidence is live, accurate and actionable.”

Ryan points to one of the most tangible results of this integration: “PSL Datatrack sits behind everything we do. From quotation to invoice, every step is controlled, recorded and visible. It allows us to identify what’s performing well and where improvements can be made, then apply that learning across the business. It’s a huge enabler of growth!”

Geoff comments: “There’s nothing more rewarding than seeing a customer flourish. Jota’s journey proves that embracing change, investing in systems and building a data-driven culture works. Their success shows what’s possible when ambition is combined with the right software tools and partners.”

The future for Jota is as ambitious as its past. With space, infrastructure, staff and systems now in place, the company is primed to double its size again while maintaining the traceability, quality and efficiency that have underpinned every step of its growth to this point.

As Ryan concludes: “Our journey shows what’s possible when you combine vision with the right systems. From four machines to 17, with integrated MRP/ERP software, ISO 9001 certification and a team empowered by live data, we can focus on delivering the best quality for our customers while continuing to grow sustainably.”

Together, PSL Datatrack’s production control software and AvISO’s quality management support have helped Jota turn good practice into consistent, measurable performance.

Jota Advanced Engineering Limited has therefore demonstrated that careful investment in systems and standards can transform a business. The company’s story serves as an inspirational example for subcontract manufacturing firms aiming to combine high-quality production with serious business growth.

For more information, visit www.psldatatrack.com or contact PSL Datatrack, Lily Hill House, Lily Hill Road, Bracknell, Berkshire, RG12 2SJ, Tel: +44 (0) 1344 827312, Email: sales@psldatatrack.com