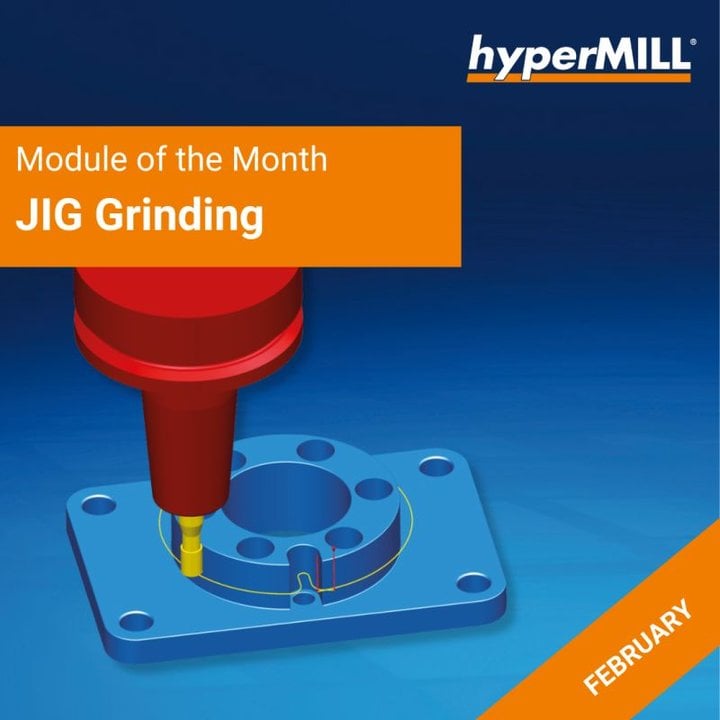

OPEN MIND Technologies has introduced the latest advancement in their manufacturing suite with hyperMILL JIG Grinding. This innovative tool allows users to perform milling, drilling, and jig grinding seamlessly within a single environment, eliminating the need for system changes.

The integration of multiple technologies within one CAM solution offers significant advantages for manufacturers, particularly those requiring high-precision components. Emphasizing accuracy where microns matter, this system promises enhanced process reliability.

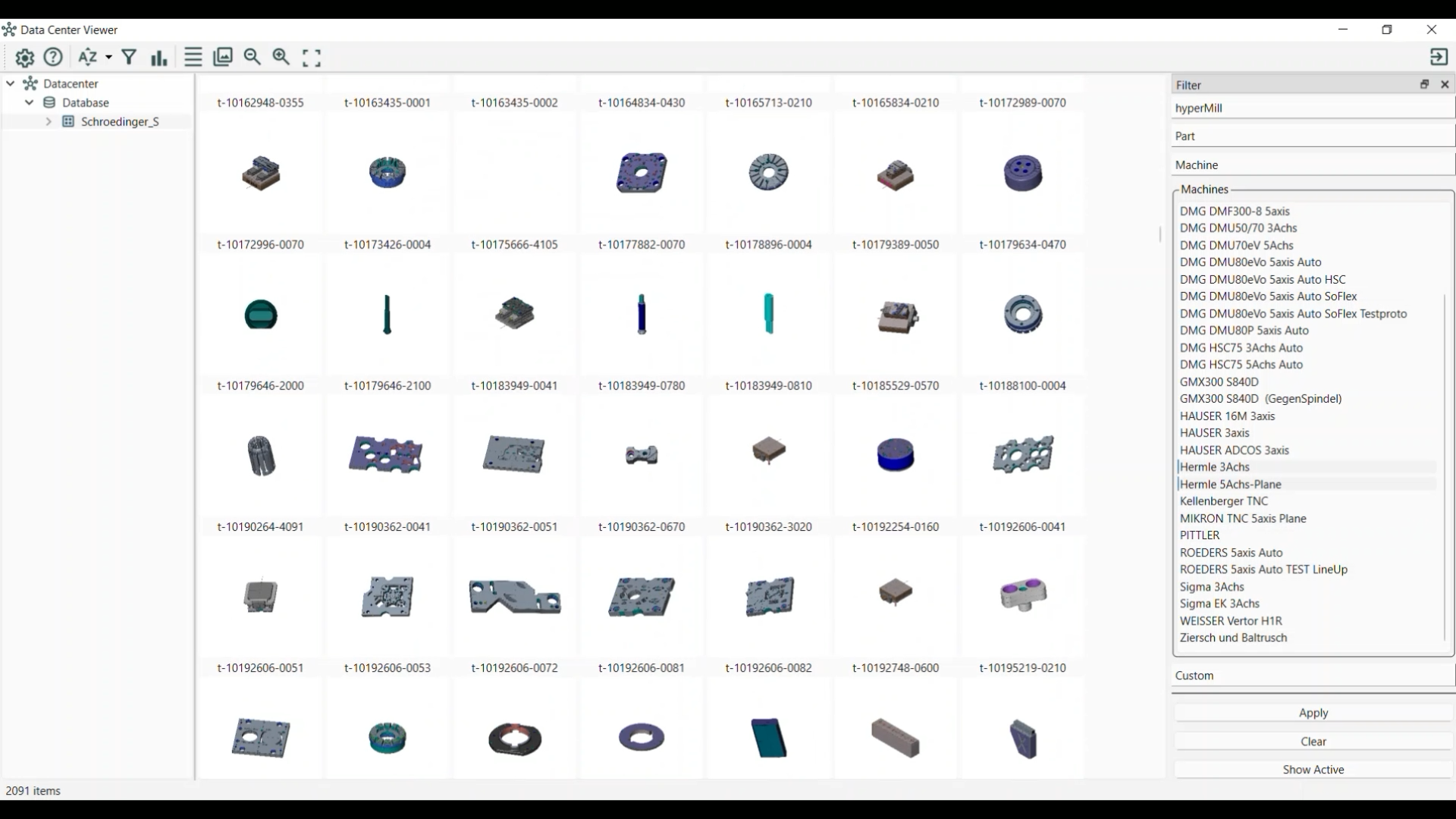

The announcement highlights the software’s capability to maintain precision while managing complex workflows. By consolidating processes, manufacturers can improve productivity and reduce the potential for error, a critical advantage in high-stakes production environments.

The hyperMILL JIG Grinding solution caters to industries where precision is essential, such as aerospace, automotive, and mold-making. Its ability to handle intricate geometries while maintaining exact specifications makes it a valuable asset for companies facing challenges at micron-level accuracy.

This development aligns with OPEN MIND Technologies’ mission to provide comprehensive, state-of-the-art solutions for the manufacturing sector. Known for its commitment to innovation, the company continues to push the boundaries of what’s possible in computer-aided manufacturing.

By offering a streamlined process and a fully integrated workflow, hyperMILL sets a new standard for precision machining, reinforcing OPEN MIND Technologies’ position as a leader in the industrial software market.

View more news from OPEN MIND Technologies AG