Okuma has unveiled its innovative Machining Navi system, designed to enhance productivity and surface finish in machining operations. The system aims to tackle common issues such as chatter, which can lead to time wastage and compromised product quality.

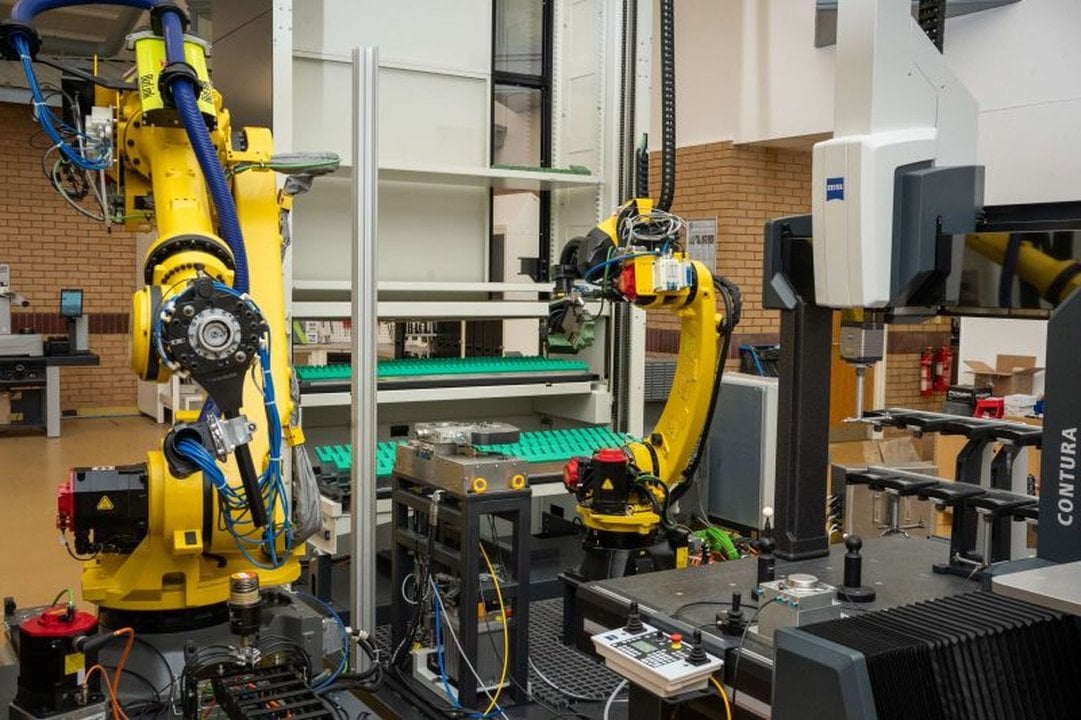

Machining Navi distinguishes itself with its ability to identify optimal spindle speeds that minimize chatter. By utilizing sensors and the OSP control, the system performs real-time monitoring of vibration. This information allows Machining Navi to either suggest or automatically implement speed adjustments, ensuring stability in cutting conditions.

The technology is compatible with both lathes and machining centres. It facilitates smoother machining processes, boosts efficiency, and offers operators greater confidence, particularly during challenging cuts.

Okuma, a prominent name in precision machining, continues its commitment to advancing manufacturing tools and technology. The introduction of Machining Navi underscores the company’s dedication to providing solutions that address prevalent manufacturing issues, enhancing overall performance in the industry.

Read this post on LinkedIn