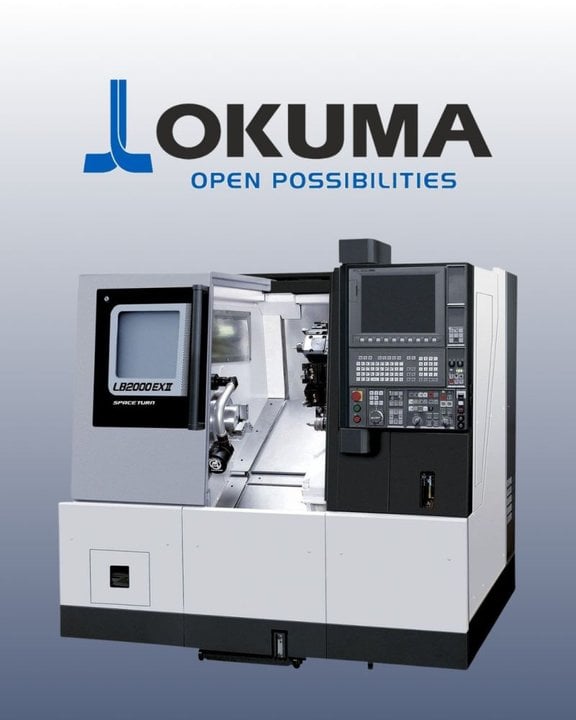

Okuma has introduced the VTM-1200YB, a versatile machine designed to enhance productivity in machining large-diameter components. This five-axis combination lathe and machining centre caters to industries requiring heavy cutting capabilities and flexible machining operations.

The VTM-1200YB promises efficient handling of turning, vertical, horizontal, and angled surface machining in a single set-up. By maintaining parts in the chuck throughout the process, the machine ensures accuracy and minimizes set-up time and cumulative tolerance errors. This feature aligns with the industry’s demand for precision and efficiency.

A key advantage of the machine is its ability to facilitate side cutting with straight end mills instead of the traditional point cutting with ball end mills. This functionality not only improves cutting efficiency but also extends tool life, a significant consideration given the high demands placed on modern machining processes. The geared spindle head contributes high torque, addressing the needs of demanding applications, while its large-diameter roller bearings support stable and precise machining. This makes it ideal for processing intricate components such as large valve bodies.

The VTM-1200YB is crafted to cater to the needs of manufacturing sectors dealing with large, high-value parts. The reduction in cycle times without sacrificing control or accuracy positions this machine as a valuable asset for companies aiming to optimize their production processes.

For further information, inquiries can be directed to NCMT Ltd via info@ncmt.co.uk.

View more news from NCMT Ltd