MACH 2020 will mark the UK launch of the D200Z 5-axis, vertical-spindle machining centre from Japanese machine tool builder, Makino, which is represented exclusively in the UK and Ireland by NCMT (www.ncmt.co.uk). On stand 130 in Hall 19 the machine will be demonstrated cycling through a ball-bar test to show the high degree of volumetric accuracy achievable, as is shown in this video: www.youtube.com/watch?v=UaxA7y5saIk

From roughing to high-speed finishing of multi-faceted and 3D contoured geometries, the D200Z boosts productivity of complex dies and moulds typically found in the automotive, injection moulding, packaging, medical and optics markets. The machine’s speed and precision provide a solid foundation for responsive, high-speed metalcutting and for the production of outstanding surface finishes that reduce or eliminate hand polishing.

The 30,000 rpm spindle and integral, direct-drive table provide quick, precise, full 5-axis machining. This capability combines with high-speed SGI.5 motion control software in the Makino Professional 6 CNC to maintain the tightest tolerances and quality requirements and ensure accurate blending of 3D surfaces, even during simultaneous 5-axis motion. All of these attributes are essential in the manufacture of modern dies, moulds and components of intricate geometry.

Designed to maximise working volume and load capacity, the compact D200Z accommodates workpiece sizes up to 300 mm in diameter, 210 mm tall and weighing up to 75 kg. The X, Y, Z axis travels of 350 mm, 300 mm and 250 mm respectively feature rapid traverse and cutting feed rates of 60 m/min. The machine utilises a lightweight B-axis structure with 0 to +180 degrees of tilt at 100 rpm. Both the B-axis and 150 rpm, 360-degree C-axis table feature direct-drive motors for accurate, high-speed operation.

Wide base castings and core-cooled ballscrews serve as a platform for enhancing overall process stability. The HSK-E50 spindle is designed with a core and jacket cooling system to control thermal growth, deflection and vibration during high-speed machining operations. As a result, the machine extends tool life in addition to providing exceptional surface finishes.

With flexible tool capacities and automation capabilities, such as the 100-tool capacity magazine with automatic tool changer and multi-pallet system, the D200Z can achieve utilisation rates of more than 80 per cent for high levels of throughput and fast return on investment.

Two other Makino vertical machining centres will feature on the NCMT stand – the 3-axis F5, also intended for mould and die work and the 5-axis DA300, which will be demonstrated producing an impeller.

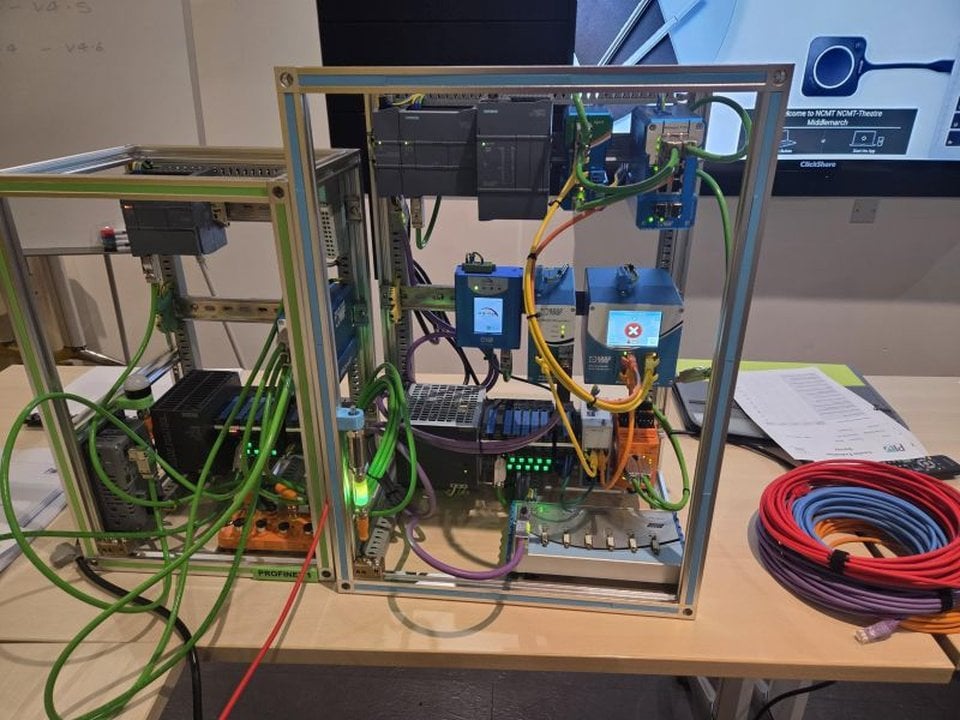

In evidence also will be the manufacturer’s Industry 4.0 package of software tools, MPmax, for real-time process monitoring and data management. With the ability to connect a multiple-machine network to a centralised computer, it allows manufacturers to retrieve, store and analyse high volumes of data in real time, enabling detection of and reaction to bottlenecks on the fly, whether it relates to underperformance or process errors.