As manufacturing and distribution demands increase, companies are turning to Automated Storage and Retrieval Systems (ASRS) to optimise their operations. These systems, once considered luxury technology, are now essential for maintaining efficient and high-performing facilities.

ASRS technology includes various types such as unit-load, mini-load, shuttle systems, carousels, and robotics. Each offers specific advantages, with the common goal of improving efficiency, reducing manual labour, and enhancing storage capabilities. With labour shortages and logistical complexities increasing costs, ASRS are becoming vital for businesses looking to maintain a competitive edge.

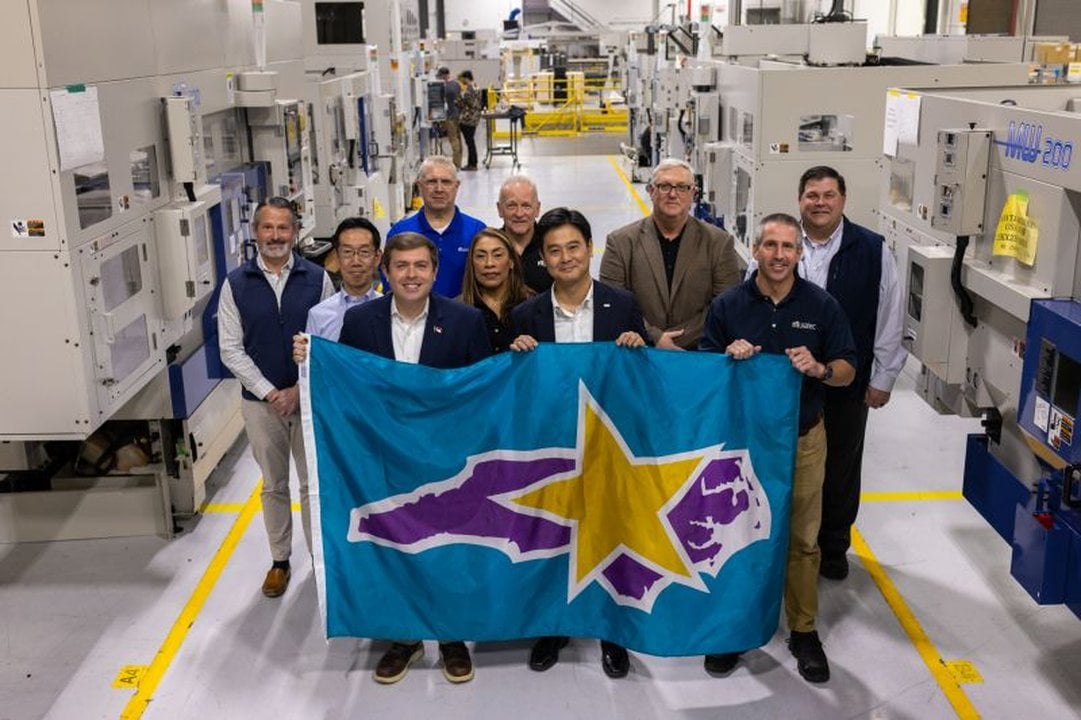

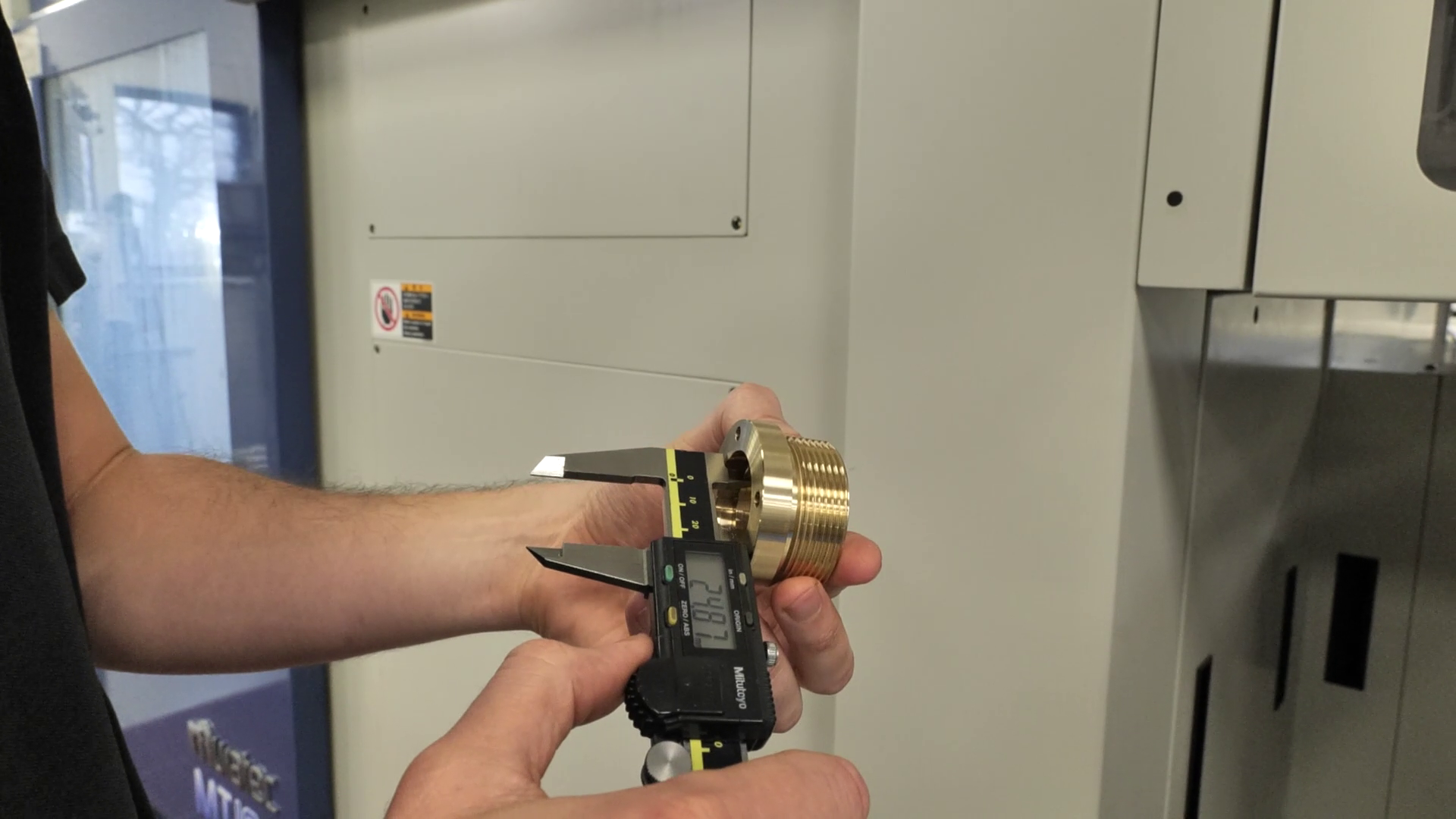

Murata Machinery USA is a leading provider specialising in designing, integrating, and supporting ASRS installations. The systems are engineered to tackle common warehouse issues, from crowded aisles and limited space to excessive overtime caused by workforce constraints.

The benefits of adopting ASRS include significant returns on investment, improved space utilisation, and streamlined operations. As a result, global companies are increasingly relying on these automated solutions to remain agile and responsive in a rapidly evolving market.

For businesses experiencing bottlenecks and operational inefficiencies, exploring ASRS can provide a much-needed roadmap to sustainable growth.

View more news from Murata Machinery USA, Inc