ZF Launches Innovative Air Compression System for Electrified Commercial Vehicles!

By Ashutosh Arora

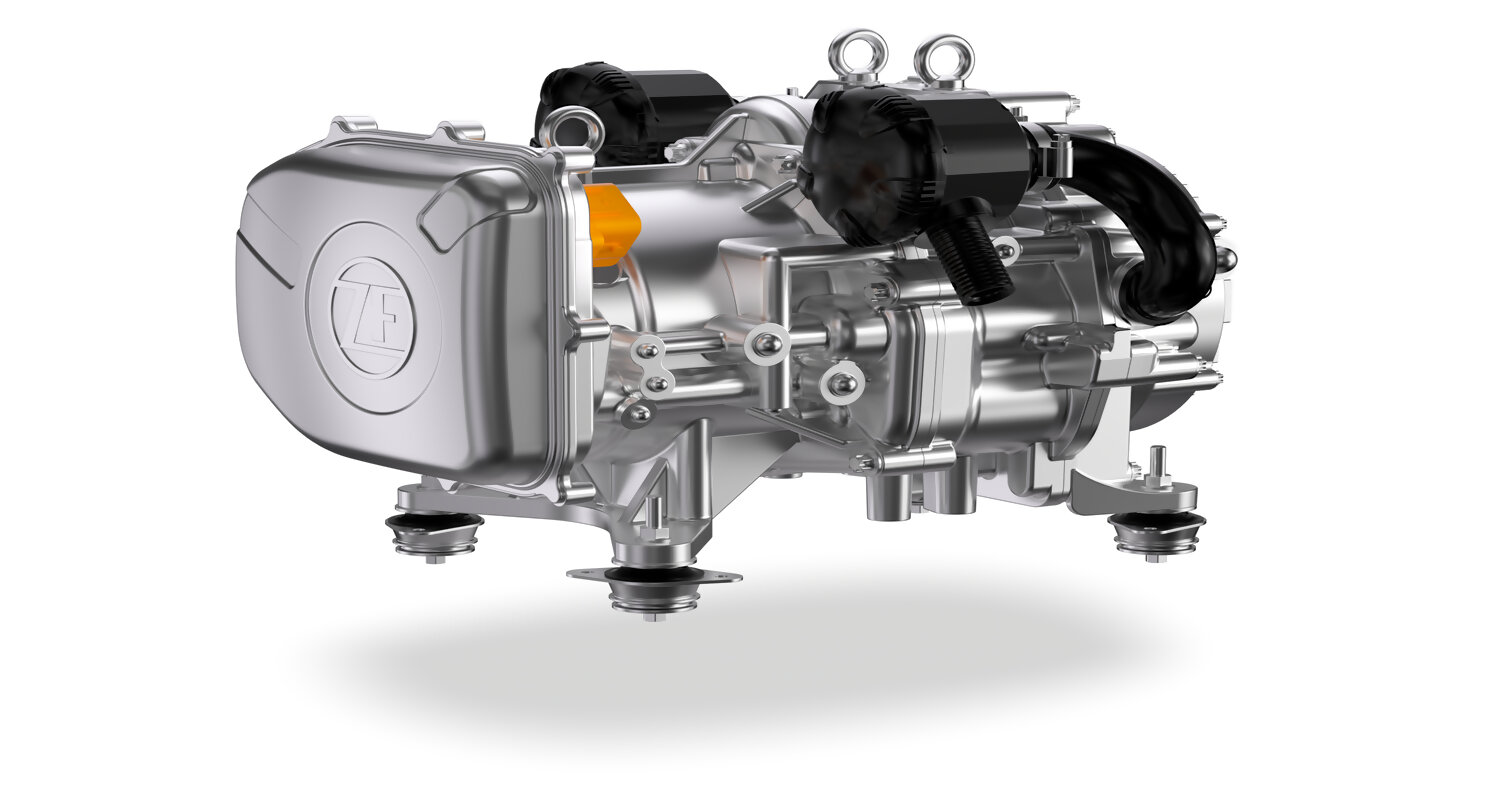

ZF’s Commercial Vehicle Solutions (CVS) division has unveiled an advanced air compression system specifically designed for electrified commercial vehicles, marking a significant step forward in the transition to sustainable mobility. The e-comp Scroll, introduced at the Advanced Clean Transportation (ACT) Expo in California and Auto Shanghai in China, promises efficient, oil-free, and low-noise air compression for a variety of hybrid, battery-electric, and fuel-cell trucks, buses, and coaches.

In traditional internal combustion engine (ICE) vehicles, air compressors are mechanically driven, powered directly by the engine. However, this system poses challenges for electric commercial vehicles (EVs), which require independently powered electric compressors. With this transition, the need for noise reduction and vibration control becomes critical—issues that are effectively addressed by the e-comp Scroll.

The e-comp Scroll utilizes scroll technology, where interlocking spirals continuously compress air. This design offers a smooth, low-vibration compression process that reduces operational noise to a level of approximately 67 dB(A) at a flow rate of 250 liters per minute—comparable to the sound level of a typical office environment. This quiet operation is a crucial advantage in the adoption of electric commercial vehicles, especially in urban areas where noise pollution is a growing concern.

Additionally, the oil-free design of the e-comp Scroll eliminates the need for oil-related maintenance, contributing to a more environmentally friendly solution. This not only reduces the vehicle’s overall environmental footprint but also lowers the total cost of ownership by eliminating costly oil changes and maintenance.

The e-comp Scroll’s integrated system includes a built-in electric motor, capable of generating up to 12.5 bar of pressure in a single stage. The motor operates at variable speeds, adjusting according to air demand to ensure maximum energy efficiency. With the inclusion of an integrated inverter and liquid-cooled shell, the system also maintains the discharge temperature below 90°C (194°F), ensuring optimal performance in varying conditions.

A key feature of the system is its ability to automatically shutdown between compression cycles, further optimizing energy consumption and enhancing the overall efficiency of the vehicle’s powertrain.

Paweł Porczyński, Head of Product Line, Chassis Solutions at ZF CVS, emphasized the strategic importance of the e-comp Scroll in achieving zero-emission vehicle targets. He stated, “Its oil-free design reduces environmental impact, eliminates oil-related maintenance, and lowers total cost of ownership.” This development highlights ZF’s continued commitment to supporting the commercial vehicle sector’s shift to electrification and sustainable mobility.

By addressing key requirements such as noise reduction, energy optimization, and environmental responsibility, the e-comp Scroll enhances ZF’s portfolio of electrification technologies, which is vital as the world moves towards a more sustainable future in transportation.

With its innovative features and focus on low-impact, high-efficiency air compression, ZF’s e-comp Scroll is set to play a pivotal role in the evolving landscape of electrified commercial vehicles.