XTJ CNC Introduces Low-Volume CNC Machining to Accelerate Custom Component Production!

XTJ CNC has announced the launch of a dedicated low-volume CNC machining service, designed to meet rising demand for flexible, high-precision manufacturing across industries. The new offering focuses on delivering custom-engineered components in small batches, enabling faster turnaround times and greater production agility for sectors such as aerospace, automotive and electronics.

The move reflects a broader shift in manufacturing priorities, where businesses increasingly seek shorter development cycles, reduced inventory exposure and faster design validation. By introducing low-volume production capabilities, XTJ CNC allows customers to manufacture custom parts without committing to large-scale production runs—making the service particularly suitable for prototypes, pilot batches and limited series production.

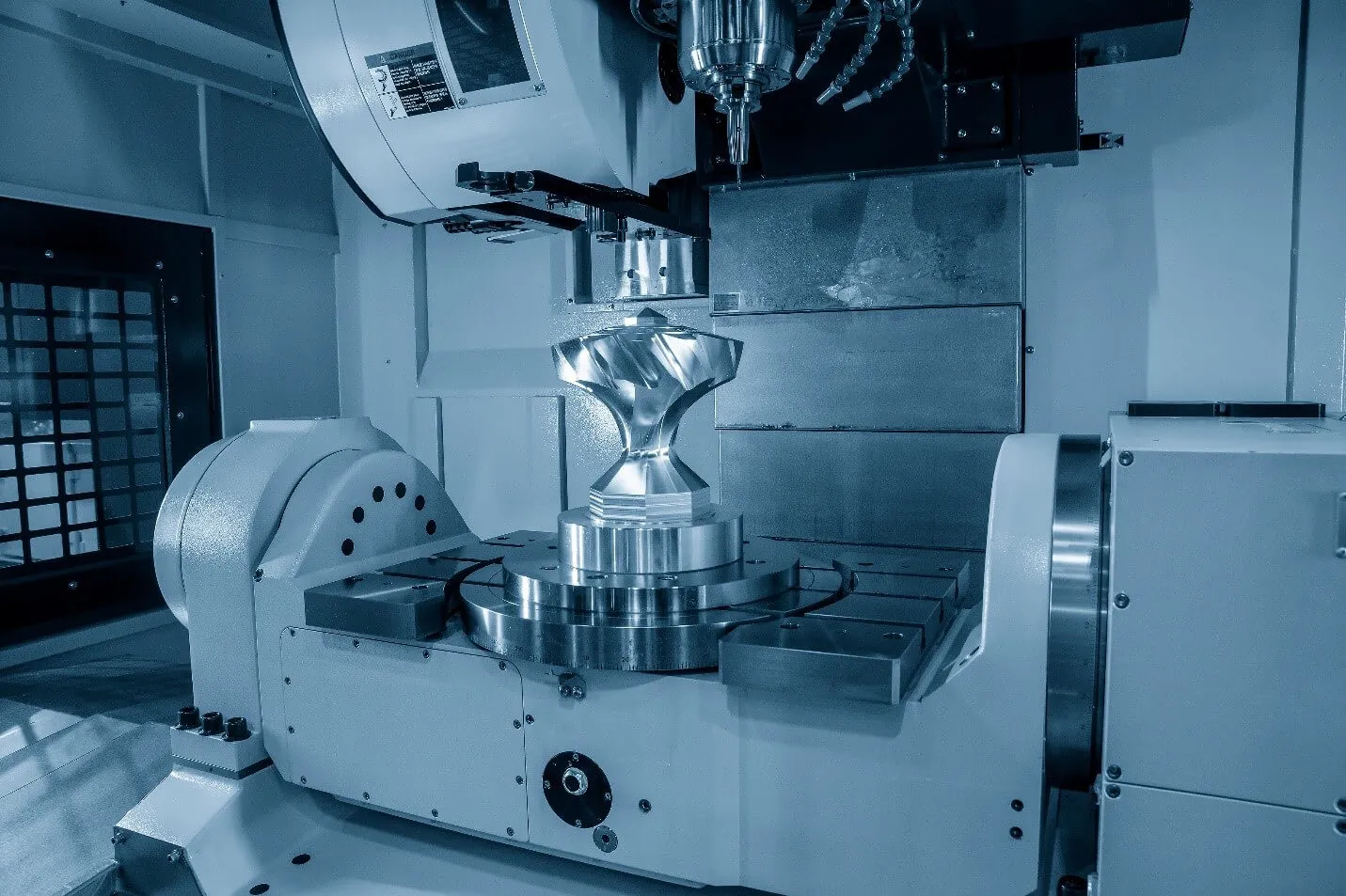

XTJ CNC leverages advanced CNC milling and turning systems to maintain tight tolerances, repeatability and consistent dimensional accuracy. The low-volume service integrates seamlessly with the company’s existing expertise in rapid prototyping and precision machining, ensuring that even small production quantities meet stringent quality standards.

By removing the traditional constraints of bulk manufacturing, the new service enables companies to accelerate product development and conduct performance testing more efficiently. Manufacturers can validate new designs, refine engineering specifications and adapt to evolving customer requirements without the financial burden of excess tooling or surplus inventory.

Hafiz Pan, Director of Operations at XTJ CNC, noted that demand for flexible production models continues to grow, particularly in industries where innovation cycles are shortening. He explained that customers now require precision-machined components in smaller quantities while maintaining uncompromising standards of performance and reliability. The low-volume machining service is designed to support these needs by combining manufacturing precision with responsive lead times.

Industries such as aerospace and automotive—where strict compliance with engineering specifications is critical—stand to benefit significantly. Electronics manufacturers, particularly those developing new devices or systems, can also leverage small-batch production to iterate designs quickly and move products to market faster.

The service supports a wide range of materials and complex geometries, ensuring versatility across diverse applications. From intricate mechanical parts to structural components requiring high surface finish quality, XTJ CNC’s advanced machining capabilities enable consistent results across varying batch sizes.

By expanding into low-volume CNC machining, XTJ CNC strengthens its position as a flexible and dependable manufacturing partner. The initiative reinforces the company’s commitment to delivering precision, speed and adaptability—key factors in supporting modern, innovation-driven industries.