Walter Expands Drion·tec D-Spade Exchangeable Tip Drill Range for Deeper Hole Machining!

Walter has expanded its Drion·tec D-Spade D5142 double-sided exchangeable tip drill portfolio, extending the tool’s capabilities for deeper and more productive holemaking in steel and cast iron applications. With the addition of new diameters ranging from 26 to 31.75 mm (1.02 to 1.25 inches), the overall diameter range of the D5142 series now spans 12 to 31.75 mm (0.47 to 1.25 inches), significantly broadening its applicability in medium to large hole drilling.

A key enhancement in the expanded range is the drill’s ability to machine holes up to 8×D in depth, complementing the existing 3×D and 5×D configurations. This increased depth capability allows manufacturers to address a wider range of applications using the same drilling platform, reducing the need for secondary tools or specialized deep-hole solutions.

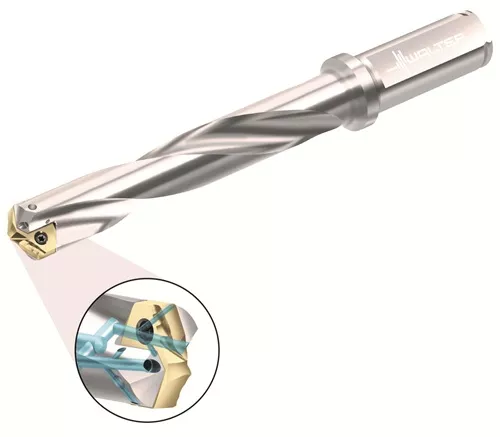

The D-Spade design is based on a double-sided exchangeable tip, providing two cutting edges per insert. This effectively doubles the number of usable cutting edges compared to conventional single-point drills, lowering the cost per cutting edge while maintaining high levels of accuracy and repeatability. When one cutting edge is worn, the tip can simply be indexed, minimizing downtime and maximizing tool utilization.

Efficient cooling and chip evacuation are central to the tool’s performance. The drill incorporates six internal coolant channels—three per side of the insert, ensuring targeted coolant delivery directly to the cutting edges. This design improves heat dissipation, extends tool life, and supports stable drilling performance, particularly at greater depths. Polished flutes further enhance chip evacuation, enabling safe and reliable machining even in demanding conditions.

The self-centering tip geometry eliminates the need for pilot holes, simplifying the drilling process and reducing overall cycle time. In addition, four straight margins on the insert contribute to improved guidance and stability in the bore, resulting in better surface finish quality and dimensional accuracy.

The replaceable drilling tip is manufactured from WPP25 fine-grain carbide and coated with a gold-colored aluminium titanium nitride (AlTiN) layer applied using HiPIMS technology. This advanced coating process delivers high wear resistance, thermal stability, and consistent performance, while the gold coloration makes wear detection easier during inspection.

The expanded Drion·tec D-Spade D5142 range is primarily optimized for steel (ISO P) and secondarily for cast iron (ISO K). It is suitable for drilling both blind and through holes, including stacked or laminate materials, with allowable entry angles up to 10 degrees and exit angles up to 20 degrees.

With the extension to larger diameters and deeper hole capability, Walter’s Drion·tec D-Spade D5142 drill offers manufacturers a flexible, cost-efficient, and high-performance solution for demanding holemaking operations, combining productivity, precision, and long tool life in a single exchangeable-tip system.