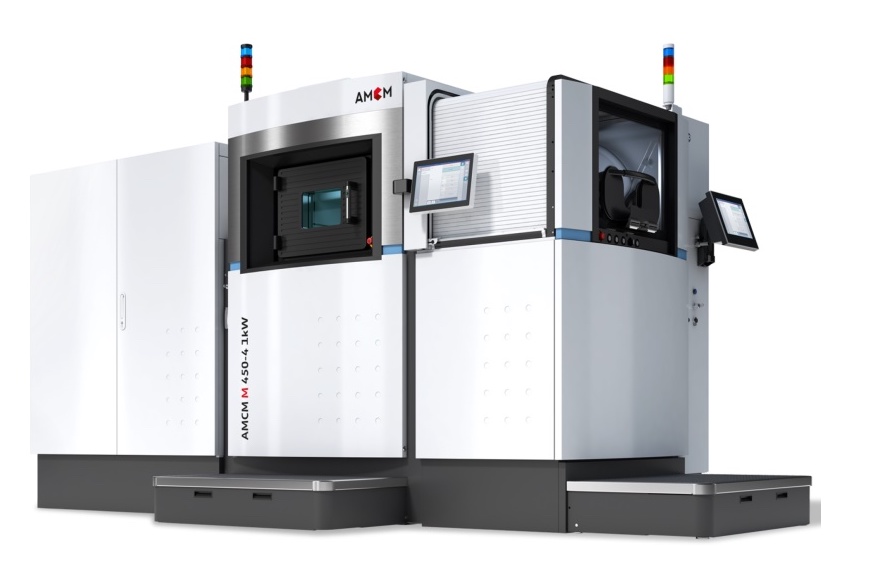

Ursa Major Expands Additive Manufacturing Capabilities with Acquisition of Three AMCM M 450-4 FLX Metal 3D Printers!

By Ashutosh Arora

Aerospace and defense innovator Ursa Major has announced a major expansion of its additive manufacturing capacity with the acquisition of three AMCM M 450-4 FLX metal 3D printing systems from EOS’ AMCM group. With this latest investment, Ursa Major now operates a total of six EOS-powered systems, underscoring its commitment to scaling hypersonics production and other advanced aerospace applications at its state-of-the-art facility in Youngstown, Ohio.

As national security and aerospace programs increasingly demand faster innovation cycles and higher-volume production of complex components, Ursa Major has turned to EOS for its proven laser powder bed fusion (LPBF) technology, deep expertise, and collaborative engineering support. The new AMCM M 450-4 FLX systems, equipped with the latest beam-shaping technology, enable higher throughput and more design flexibility, positioning Ursa Major to deliver advanced propulsion solutions at greater speed and scale.

Nick Doucette, Vice President of Operations at Ursa Major, praised the partnership, stating, “EOS and AMCM have been fantastic to work with – proven reliability, a responsive U.S. service team, and the largest deployed fleet of metal AM systems in the country. Beyond that, they bring an openness and engineering partnership. Together, we’re challenging legacy approaches to part qualification and process qualification, pushing the entire additive industry forward.”

This collaboration goes well beyond the hardware itself. Ursa Major is actively leveraging EOS’ laser toolpath API with full engineering support from EOS’ Additive Minds consulting team. This integration allows Ursa Major’s engineers to pursue software-driven customization, unlocking new levels of design freedom and efficiency that align with the company’s forward-looking manufacturing strategy.

“Ursa Major’s work with EOS demonstrates the next era of additive manufacturing – where advanced users are empowered to innovate on their own terms,” commented Greg Hayes, Global SVP of Additive Minds at EOS. “With EOS technology and our engineering support, this collaboration shows how OEM and user together can unlock progress at a pace never seen before.”

The three new M 450-4 FLX systems join an existing fleet that includes an AMCM M 290-1 FLX and two EOS M 400 systems. All six machines will be deployed at the Youngstown, Ohio site, which is rapidly emerging as a hub for Ursa Major’s U.S.-based additive production. By consolidating advanced manufacturing in this location, the company is reinforcing its commitment to building a secure, scalable, and resilient supply chain for critical aerospace and defense applications.

“Ursa Major exemplifies what’s possible when a forward-thinking company leverages EOS technology to its fullest potential,” said Glynn Fletcher, President of EOS North America. “Their team’s deep technical fluency and bold vision inspire us. We’re proud to support them as they shape the next decade of advanced manufacturing in the defense industry.”

With this investment, Ursa Major is strengthening its role as a key partner to U.S. defense and aerospace customers, helping to accelerate hypersonics development and ensuring American leadership in next-generation propulsion technologies.