United Machining Solutions’ Wire EDM Supports Lights-Out Machining!

By Ashutosh Arora

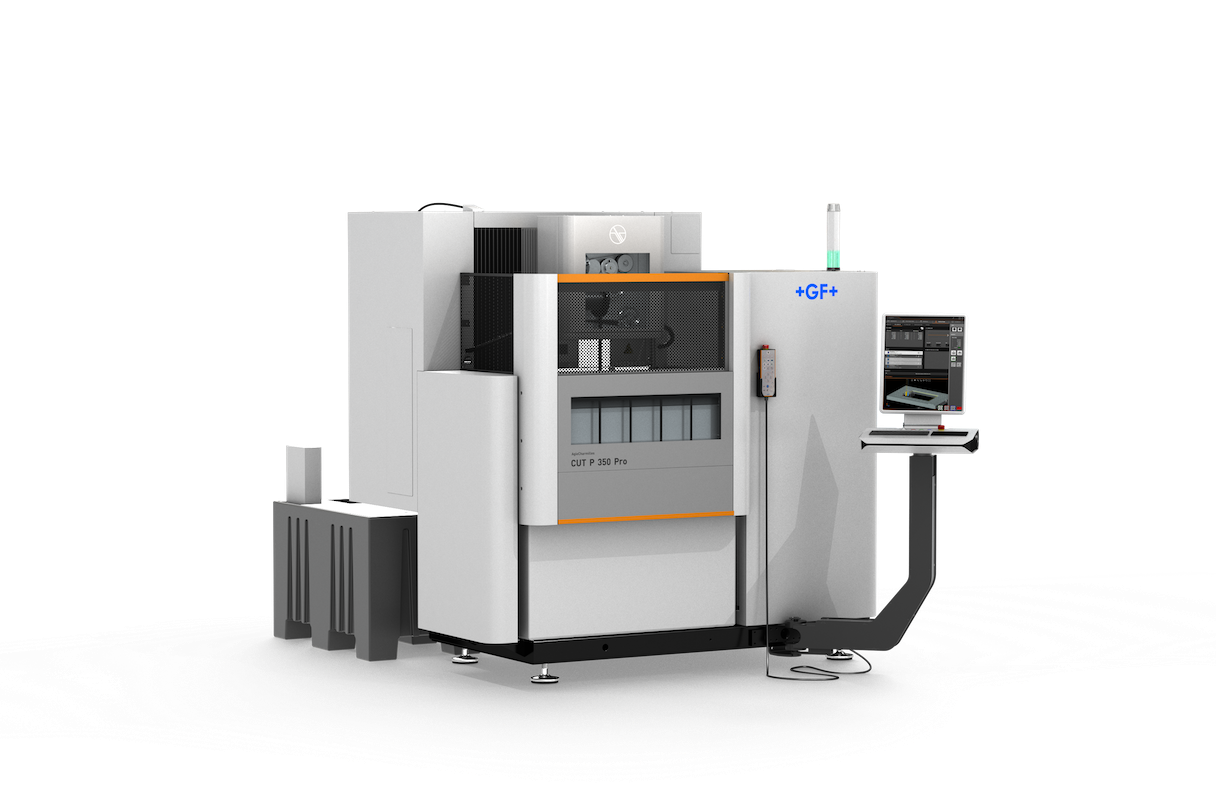

United Machining Solutions continues to push the boundaries of precision manufacturing with its advanced Agie Charmilles Cut P 350 Pro wire EDM, a machine engineered to deliver exceptional accuracy, surface quality, and automation capabilities. Designed for a wide spectrum of applications, this machine is tailored to meet the evolving needs of modern manufacturers seeking higher productivity, greater reliability, and minimal operator intervention through lights-out machining.

At the heart of the Cut P 350 Pro is its Intelligent Power Generator technology, which optimizes the electrical discharge process to achieve remarkably smooth surface finishes of up to Ra 0.08 µm. This precision ensures that components requiring tight tolerances and superior surface quality can be produced efficiently without extensive post-processing. The system’s integrated thermal regulation plays a vital role in maintaining consistent performance, allowing the machine to deliver an impressive accuracy of ±2 µm, even during extended machining cycles.

The machine incorporates a dual measuring system consisting of linear scales and rotary encoders on the X, Y, U, V, and Z axes. This setup not only enhances precision but also ensures superior protection against potential collisions. In the event of a collision, the system intelligently distinguishes between false and real movement—recognizing when the linear scales detect no movement while the rotary encoders do—promptly halting operations to prevent damage to the workpiece or the machine structure. This safety mechanism reflects United Machining Solutions’ commitment to operational integrity and long-term equipment reliability.

One of the most significant engineering advancements in the Cut P 350 Pro is its Quadrax mechanical design, which keeps both the table and work tank stationary during operation. By eliminating unnecessary movement, this configuration allows the machine to handle heavy workpieces with exceptional stability and precision. The independent U/V and X/Y axes, with equal travel lengths and lower moving mass, contribute to enhanced cutting flexibility—capable of performing large, tapered cuts of up to 45 degrees across the full length of the Z-axis. This makes the machine ideal for complex geometries and intricate contours often required in industries such as aerospace, automotive, and medical manufacturing.

Adding to its robust design, the machine’s base is constructed from Rhenocast, a high-performance material known for its low thermal conductivity and superior vibration damping. This structural choice minimizes thermal distortion and vibration effects, ensuring dimensional accuracy and consistent machining results throughout prolonged production runs.

Complementing its hardware capabilities, the Uniqua human-machine interface (HMI) provides an intuitive control experience, combining ease of use with powerful process monitoring and optimization tools. Operators can easily program complex cutting paths, manage automation sequences, and monitor performance metrics—all from a user-friendly, modern interface.

The combination of precision, automation, and intelligent design positions the Agie Charmilles Cut P 350 Pro as a cornerstone for manufacturers aiming to embrace lights-out machining. With its balance of reliability, flexibility, and technological sophistication, United Machining Solutions’ latest EDM system empowers manufacturers to achieve higher throughput, reduced downtime, and sustained precision—making it a formidable asset in any advanced machining environment.