Uddeholm’s Corrax Unlocks Additive Manufacturing for Mold Tooling with High-Performance Stainless Steel!

By Ashutosh Arora

Uddeholm USA is pioneering a new era in mold tooling with the introduction of Corrax, the first stainless steel powder developed specifically for additive manufacturing (AM) in tooling applications. Corrax combines the performance of conventional tool steels with the design freedom and efficiency of 3D printing—ushering in advanced capabilities for manufacturers seeking durable, corrosion-resistant, and highly polishable mold solutions.

Engineered for additive manufacturing from the ground up, Corrax powder enables the production of complex, high-performance tooling components with properties tailored for modern moldmaking. The material offers exceptional corrosion resistance and surface finish potential, outperforming many standard corrosion-resistant mold steels traditionally used in plastic molding environments.

One of Corrax’s standout attributes is its adjustable hardness range of 36–50 HRC, achieved through an aging treatment at 425–600°C (790–1110°F). This flexibility allows moldmakers to fine-tune mechanical properties based on application needs. Additionally, Corrax maintains excellent dimensional stability during heat treatment and machining, making it ideal for precision parts. A key benefit is its resistance to forming a hard “white layer” post-EDM, reducing the risk of surface cracking and easing post-processing requirements.

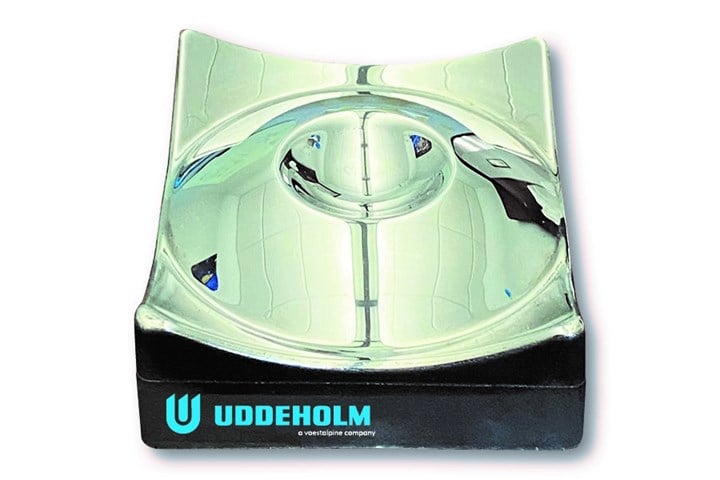

Corrax also excels in polishability, capable of achieving high-quality SPI A1 surface finishes even on printed parts—an essential requirement for mold cavities where optical clarity or smooth texture is crucial. This makes it especially valuable in sectors such as automotive interiors, medical device housings, and consumer packaging.

Available in powder form for additive manufacturing and in flat and round bar stock for hybrid builds, Corrax provides toolmakers with versatile production options. Hybrid tooling—combining 3D printed inserts with conventionally machined bases—allows for cost-effective manufacturing while enabling design complexity where it matters most.

By offering additive-ready tooling material, Uddeholm has bridged the gap between innovation and practicality, allowing manufacturers to adopt 3D printing without compromising on strength, durability, or surface quality. Corrax is not just a material—it’s a gateway to tooling innovation, helping reduce lead times, enhance design flexibility, and improve part performance across the moldmaking industry.