Tungaloy’s DLC-Coated DS2000 Series Delivers High-Precision Machining for Aluminum and Non-Ferrous Metals!

Tungaloy Corporation has expanded its tooling portfolio with the DS2000 Series, a range of DLC-coated tools specifically optimized for machining aluminum and non-ferrous metals. The series is designed to address growing industry demand for higher productivity, longer tool life, and superior surface finish when working with lightweight materials that are increasingly used across modern manufacturing sectors.

The shift toward lightweight design and energy efficiency has accelerated adoption of aluminum alloys and non-ferrous metals in industries such as automotive, aerospace, semiconductors, robotics, and construction materials. While these materials offer an excellent balance of strength and weight, they also present machining challenges—most notably built-up edge (BUE), material adhesion, and burr formation. These issues can lead to inconsistent surface quality, unstable tool life, and unplanned downtime, creating a need for tooling solutions that can deliver both reliability and precision.

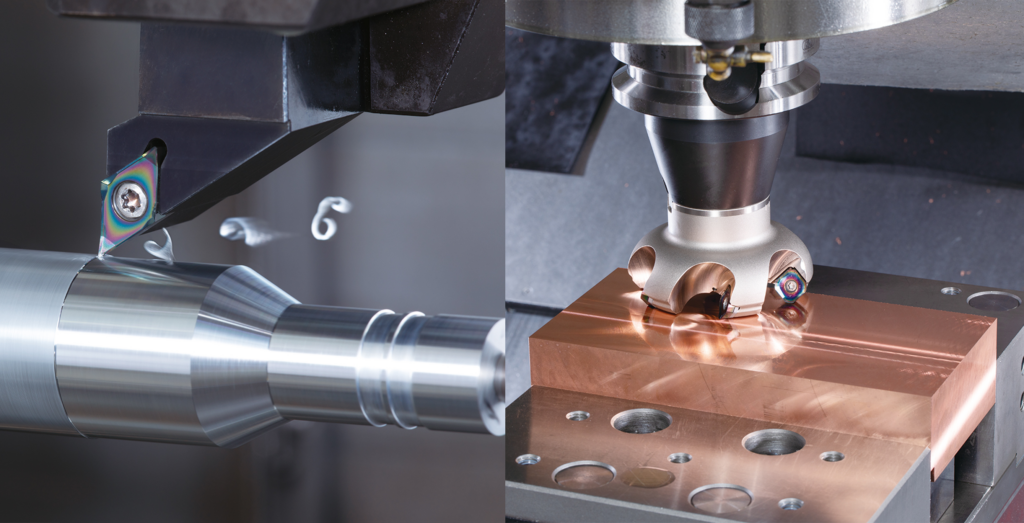

Tungaloy’s DS2000 Series has been engineered to directly address these challenges. The tools feature a diamond-like carbon (DLC) coating that provides excellent resistance to adhesion and built-up edge formation, enabling stable cutting even in demanding high-speed or high-volume applications. This results in a bright, high-quality surface finish that reduces the need for secondary finishing operations and supports tighter dimensional control.

In addition to adhesion resistance, the DS2000 Series offers high hardness and strong heat resistance, helping to suppress wear progression during prolonged machining cycles. This contributes to extended and predictable tool life, allowing manufacturers to reduce tool changes, improve process stability, and lower overall machining costs. Strong coating adhesion further ensures consistent performance, even under aggressive cutting conditions.

The series also includes a dedicated non-ferrous chipbreaker lineup, with AL (positive) and 28 (negative) geometries. These chipbreakers are designed to improve chip control and minimize chip entanglement—an important consideration when machining aluminum, where long, continuous chips can disrupt automation and compromise safety. Improved chip evacuation supports smoother operations and higher spindle utilization in both turning and milling processes.

According to Tungaloy, the DS2000 Series is particularly well suited for non-ferrous turning applications where surface finish consistency and tool life are critical, especially in environments where adhesion and BUE have traditionally limited performance. By combining coating technology, optimized geometry, and application-specific chip control, the DS2000 Series enables manufacturers to achieve higher productivity without sacrificing quality.

Overall, the DS2000 Series reflects Tungaloy’s focus on developing application-driven tooling solutions that support modern manufacturing trends. As the use of aluminum and non-ferrous metals continues to expand, tools designed specifically for these materials will play an increasingly important role in achieving efficient, reliable, and high-precision machining operations.