Tungaloy Expands SolidMeister End Mills for Enhanced Performance in High-Hardness Machining!

By Ashutosh Arora

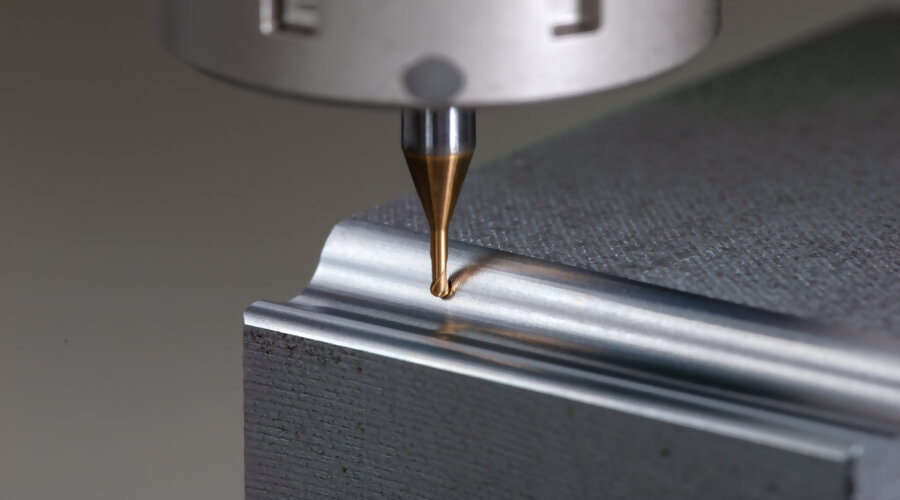

Tungaloy has introduced new additions to its SolidMeister solid carbide end mill series, offering 0.3-mm small-diameter end mills and the high-performance AH8005 grade designed to provide unmatched precision, stability, and tool life in demanding high-hardness material machining applications.

The SolidMeister series is tailored to meet the high demands of industries such as mold and die, aerospace, and medical component manufacturing. With advanced engineering, these end mills are built to improve machining efficiency, tool stability, and overall tool life, especially in high-speed and high-feed milling operations.

The new small-diameter end mills are crafted for ultra-fine precision machining, offering optimal sharpness and stable cutting performance. The design ensures that these end mills can deliver superior surface finishes, making them ideal for intricate, high-precision components. These tools feature wear-resistant, high-hardness PVD-coated AH8005 grade material, which is optimized for machining hardened steel and heat-resistant alloys. The PVD coating significantly enhances tool life and provides excellent oxidation resistance, enabling reliable performance even under high cutting speeds.

Key Features for Enhanced Productivity:

- Extended Tool Life: The PVD coatings on the SolidMeister series effectively reduce tool wear, ensuring increased stability and longer-lasting performance in high-speed machining applications.

- Optimal Chatter Resistance: The series features variable pitch and helix designs, which improve cutting smoothness and minimize vibration, helping to reduce the risk of chatter and ensuring a more stable cutting process.

- Reduced Machining Time: With high feed capabilities, these end mills increase productivity and are designed to meet the needs of precision component manufacturing. They enable faster processing of materials, leading to shortened cycle times and more efficient operations.

The SolidMeister end mill series is specifically engineered for high-hardness materials, such as hardened steels and heat-resistant alloys, which are commonly encountered in demanding manufacturing sectors. The introduction of small-diameter end mills enables more precise and controlled machining, particularly for industries that require components with tighter tolerances and superior surface finishes.

Tungaloy’s SolidMeister end mills provide a combination of precision, stability, and extended tool life, making them ideal for manufacturers in industries like aerospace, medical, and mold and die. With the incorporation of advanced coatings and optimized geometries, the SolidMeister series delivers outstanding performance in high-speed and high-feed milling applications, allowing companies to improve both productivity and part quality in their high-hardness material machining processes.