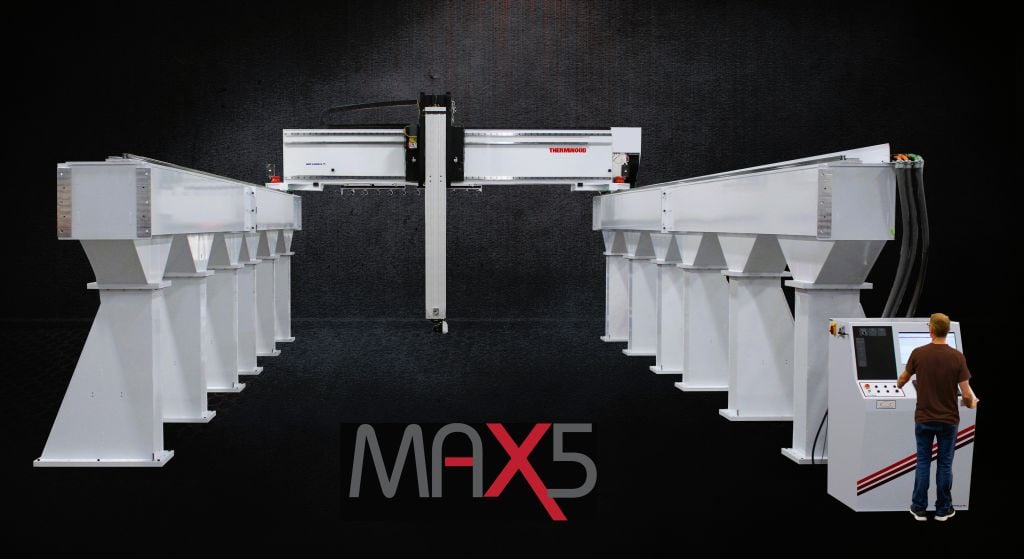

Thermwood’s Max5: A Heavy-Duty Five-Axis CNC Built for Large-Scale Precision Machining!

By Ashutosh Arora

Thermwood Corporation has introduced its Max5 five-axis CNC machine, purpose-built for high-clearance, large-format applications in industries such as aerospace, marine, automotive, and construction. This robust system is engineered to deliver exceptional power, precision, and structural integrity when handling oversized components and demanding materials.

At the heart of the Max5 is its ability to manage massive parts and molds with ease. With a 9-foot vertical Z-axis clearance, optional widths of 10 or 15 feet, and lengths extending up to 60 feet, the Max5 offers the flexibility and space needed for producing everything from complex aerospace structures to large-scale molds used in boat building and architectural forms.

Driving its performance is a 17-horsepower liquid-cooled spindle, capable of withstanding extended machining cycles while maintaining tight tolerances. The machine comes with a six-position automatic tool changer as standard, which can be expanded to 18 positions, allowing for seamless multi-tool operations. Additional smart features such as automatic tool length and diameter measurement and an automatic lubrication system reduce manual intervention and enhance reliability.

Thermwood has equipped the Max5 with its SuperControl system featuring Smart Router Technology, enabling advanced machining strategies, faster cycle times, and superior control over complex five-axis tool paths. The router achieves indexing speeds up to 2,100 inches per minute (ipm), significantly boosting productivity in high-volume or time-sensitive operations.

From a construction standpoint, the Max5 sets itself apart with a stress-relieved, engineered steel gantry, precision-machined internal bracing, and vertical support columns designed to resist deformation under heavy loads. Optional upgrades such as a floating aluminum worktable with drilled and tapped surface further enhance the machine’s adaptability for intricate fixturing and workpiece stability.

Built using 3D modeling and finite element analysis (FEA), the Max5 is structurally optimized to endure the high-stress demands of modern, multi-axis machining. This ensures consistent performance and high repeatability—even under the extreme loads common in aerospace composite tooling or high-density marine materials.

In summary, the Thermwood Max5 is a comprehensive machining solution that merges large-scale capabilities with high-performance design. It’s a perfect fit for manufacturers who need uncompromising strength, accuracy, and automation to meet the growing complexity of their components and assemblies.