Synergy Additive Manufacturing Secures SBIR Phase I Contract to Advance Coating Technologies for Naval Helicopter Components!

By Ashutosh Arora

Synergy Additive Manufacturing LLC has been awarded a Phase I Small Business Innovation Research (SBIR) contract by the Naval Air Systems Command (NAVAIR), marking a pivotal step in the development of extremely high-speed laser cladding (EHLA) technologies for aerospace-grade titanium components. This initiative is aimed at supporting the U.S. Navy’s mission to increase the durability and reduce the lifecycle costs of critical helicopter systems through advanced material solutions and innovative coating techniques.

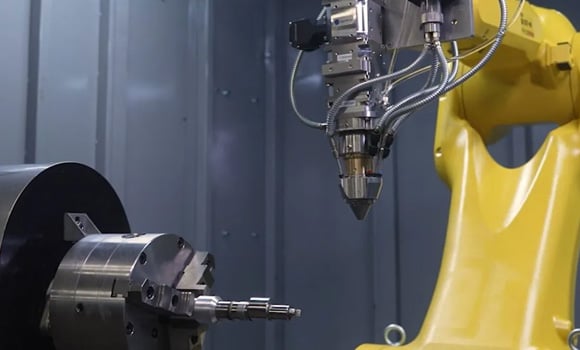

The project will focus on the development of precision cladding processes and advanced material systems optimized for titanium alloys, particularly for use in cylinder bores found in vital helicopter components. By leveraging EHLA techniques, Synergy aims to achieve rapid, distortion-free, and defect-free deposition, resulting in enhanced wear resistance, reduced material waste, and extended service life for mission-critical parts.

“This SBIR award gives us the opportunity to advance innovative material solutions, processes, and equipment that will not only support the operational readiness of our defense forces but also enhance the competitiveness of the U.S. manufacturing industry,” stated Aravind Jonnalagadda, Chief Technology Officer at Synergy Additive Manufacturing. He emphasized Synergy’s commitment to pushing the boundaries of laser processing technologies and meeting the stringent performance standards of modern defense applications.

The adoption of EHLA technology in military aerospace components represents a major advancement over traditional overhaul and repair methods, offering faster turnaround, minimal heat input, and superior coating performance. The success of this Phase I project could pave the way for broader adoption of EHLA across naval aviation platforms and future opportunities under Phase II and III SBIR programs.

This contract further cements Synergy’s position as a leading innovator in laser-based additive manufacturing and surface engineering, with a growing portfolio of defense and aerospace applications. By aligning advanced manufacturing capabilities with national defense priorities, Synergy is poised to contribute meaningfully to the modernization and sustainability of the U.S. Navy’s fleet.