Sumitomo’s New Turning Grades Enhance Tool Life for Machining Titanium Alloys!

By Ashutosh Arora

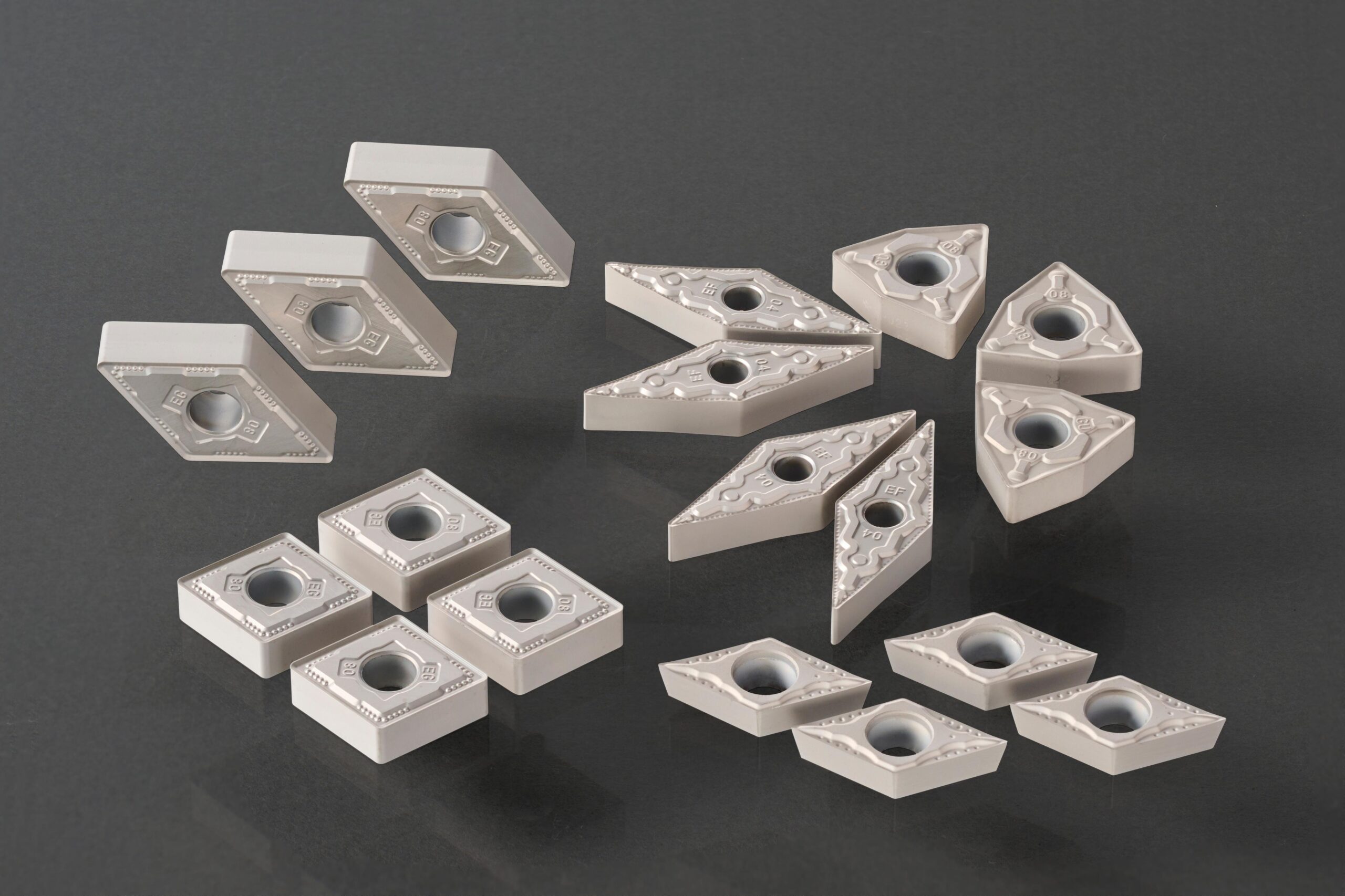

Sumitomo Electric Carbide has unveiled two new turning grades, AC9115T and AC9125T, designed specifically for machining titanium alloys. These advanced grades incorporate Sumitomo’s innovative Absotech coating technology and a tungsten carbide-based composition that significantly increases wear resistance and tool longevity when working with titanium alloys.

Titanium alloys are widely used in industries such as aerospace and medical due to their lightweight, high strength, and exceptional corrosion resistance. However, machining these materials has traditionally posed challenges, including high wear rates on cutting tools and potential chemical reactions between the material and the tool. The new AC9115T and AC9125T grades address these issues effectively, making them ideal for a range of titanium alloy applications.

The AC9115T is optimized for general-purpose machining, while the AC9125T is tailored for interrupted machining operations. Both grades feature Sumitomo’s unique physical vapor deposition (PVD) Absotech coating, which is combined with the industry’s first tungsten carbide-based composition. This composition suppresses chemical reactions with titanium alloys and enhances wear resistance, making these turning grades particularly effective in reducing the friction coefficient by up to 75%. As a result, users can achieve longer tool life and improved performance when machining titanium alloys.

This breakthrough is expected to have a significant impact on industries like aerospace, where titanium alloys are frequently used, and in the medical sector, where biocompatibility is key. By offering longer-lasting tools with better performance, Sumitomo’s new turning grades help manufacturers improve productivity and reduce costs associated with tool wear and replacement.