Starrag’s Heckert H100 Compact Machining Center: Heavy Duty Performance in a Small Footprint!

By Ashutosh Arora

Starrag, a renowned name in precision machine tools, has introduced the Heckert H100, a compact yet powerful machining center designed to handle large, heavy parts with impressive efficiency. With its robust capabilities, the Heckert H100 offers a perfect balance of precision, speed, and performance in a machine that takes up minimal floor space.

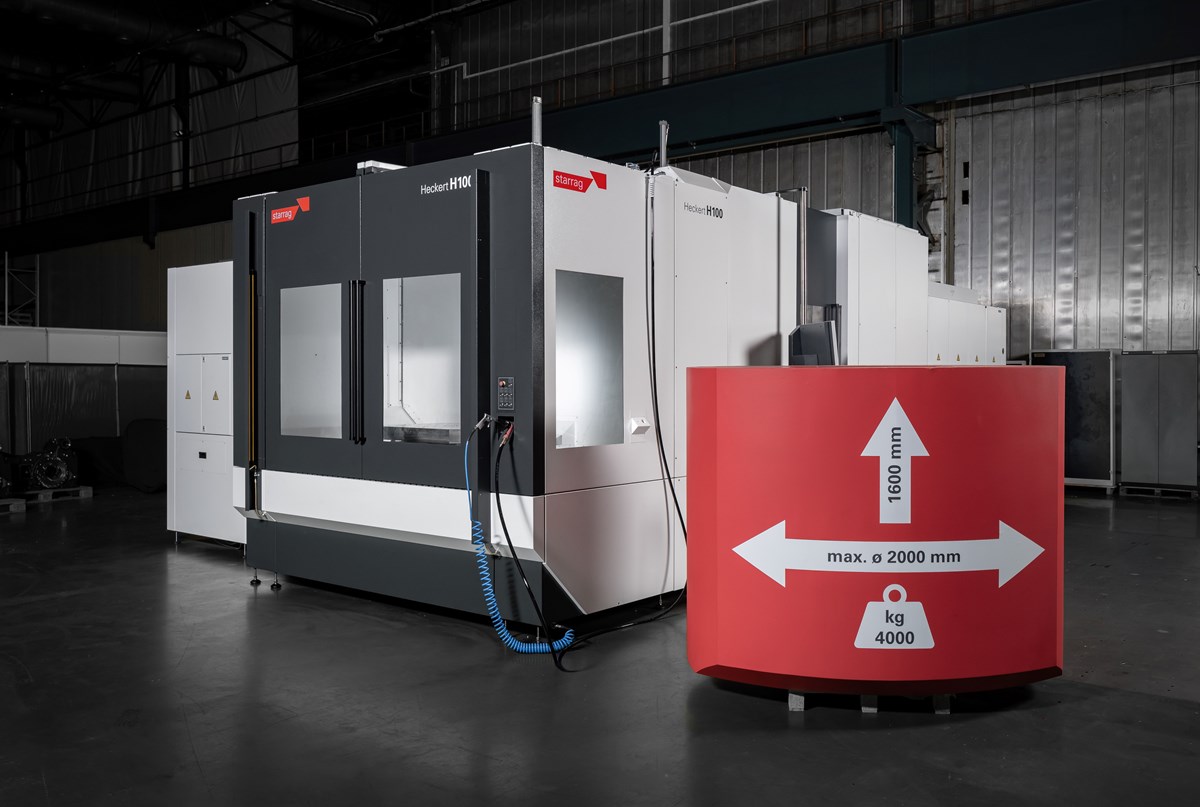

The Heckert H100 is a standout in its class due to its compact design, making it an ideal solution for manufacturing environments where space is at a premium but large and heavy parts need to be machined. With a pallet size of 39 inches (1,000 mm) and a loading weight capacity of 8,818 lbs (4,000 kg), this machine is tailored to meet the needs of industries that deal with heavy-duty parts, such as commercial vehicles and high-precision mechanical engineering.

Despite its smaller footprint, the Heckert H100 can accommodate parts that traditionally would require much larger machining centers, allowing manufacturers to optimize their workspace while maintaining high production standards.

The Heckert H100 features dimensions of 350″ × 181″ (8,900 mm × 4,600 mm) and offers travel paths of 69″ (1,750 mm) along the X-axis, 51″ (1,300 mm) along the Y-axis, and 55″ (1,400 mm) along the Z-axis. This generous travel capability allows for the machining of large parts while maintaining the compact footprint of the machine. Additionally, customers have the option to extend the Y-travel up to 55″ (1,400 mm) and the Z-travel up to 71″ (1,800 mm), further enhancing the machine’s versatility.

The displacement circle diameter of 79″ (2,000 mm) ensures that the machine can handle a variety of part sizes, making it suitable for a range of applications, from high-precision components to larger-scale production runs.

One of the key features of the Heckert H100 is its ease of automation. The machine is designed with extended clamping hydraulics and simplified interfaces, allowing for smooth integration with pallet storage systems and robotic cells. This capability helps increase productivity by reducing manual handling and enabling continuous machining without the need for frequent human intervention.

The machine is also equipped with central connections for technological cold water, cooling lubricant, and data exchange, further improving its integration into the customer’s existing infrastructure. This design ensures a seamless workflow, minimizing setup time and maximizing machine uptime.

Starrag has ensured that the Heckert H100 can be tailored to meet the specific needs of its customers. The machine offers a larger selection of spindles, which can be chosen based on the specific requirements of the parts being machined. Whether manufacturers need higher speeds, greater precision, or additional power, the Heckert H100 can be customized to suit a wide range of applications.

The Heckert H100 is particularly well-suited for industries that require high-precision machining, such as commercial vehicle manufacturing and mechanical engineering. Its compact size combined with the ability to handle heavy parts makes it an excellent choice for operations where space constraints and heavy-duty performance are both critical factors.

In conclusion, the Starrag Heckert H100 compact machining center is a versatile solution that provides manufacturers with the capability to machine large and heavy parts in a smaller footprint. With its high-performance features, ease of automation, and customization options, the Heckert H100 is poised to meet the evolving needs of industries that demand both precision and power in their machining operations.