Star SU Chamfer Hob Delivers Burr-Free Precision in Gear Manufacturing!

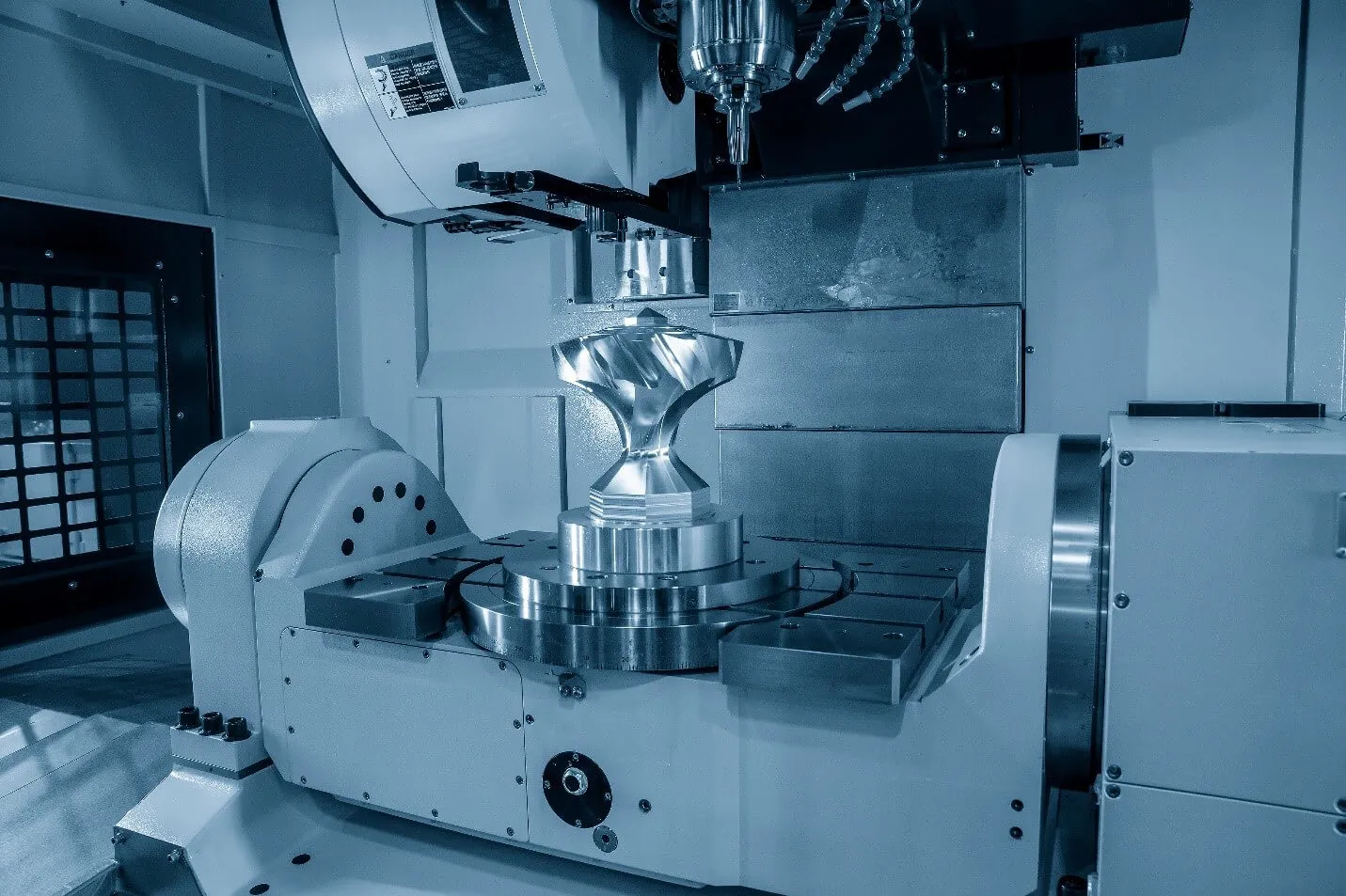

Star SU has introduced an advanced chamfer hob designed to enhance efficiency and accuracy in gear production. Engineered to create burr-free chamfers in a single, seamless process, the tool combines the functionality of a traditional hob with integrated chamfering capability—eliminating the need for secondary finishing operations.

In high-precision gear manufacturing, burr formation and inconsistent chamfer quality can lead to assembly issues, noise, premature wear and additional processing time. The Star SU chamfer hob addresses these challenges by performing chamfering directly during the hobbing cycle. By integrating the two operations, manufacturers can streamline production, reduce tool changes and improve cycle times without compromising quality.

The chamfer hob delivers high-precision, burr-free chamfers while maintaining dimensional accuracy across various gear types. Its design supports long tool life and low cost per part, making it particularly suitable for high-volume production environments. Optimized cutting geometry ensures smooth chip evacuation and consistent edge quality, even under demanding machining conditions.

A key strength of the system lies in its versatility. The chamfer hob can be tailored to specific gear geometries, allowing it to handle both standard gear profiles and more complex designs with interference limitations. This customization ensures maximum reliability and repeatability across different applications.

The tool also addresses common chamfering challenges encountered in complex gear configurations. It is effective in scenarios such as shaft gears with shoulder interference, ring gears with fixture interference and gears with inclined lateral surfaces. By adapting to these geometries, the chamfer hob helps manufacturers maintain consistent chamfer quality even in difficult-to-machine areas.

For large-scale gear production, the integrated approach offers significant operational benefits. Eliminating secondary chamfering processes reduces handling, setup time and cumulative tolerance stack-ups. The result is improved throughput, enhanced surface finish and greater process stability.

With increasing demand for precision gears in automotive, aerospace, heavy machinery and industrial transmissions, manufacturers require tooling solutions that deliver both accuracy and productivity. Star SU’s chamfer hob aligns with these needs by combining precision engineering with efficient process integration.

By reducing burr formation, extending tool life and supporting customized gear profiles, the chamfer hob strengthens process reliability and helps manufacturers achieve higher productivity with lower overall machining costs.