Spreitzer Unveils the MZX: A Revolutionary Mechanical Centric Vise for Modern Manufacturing!

By Ashutosh Arora

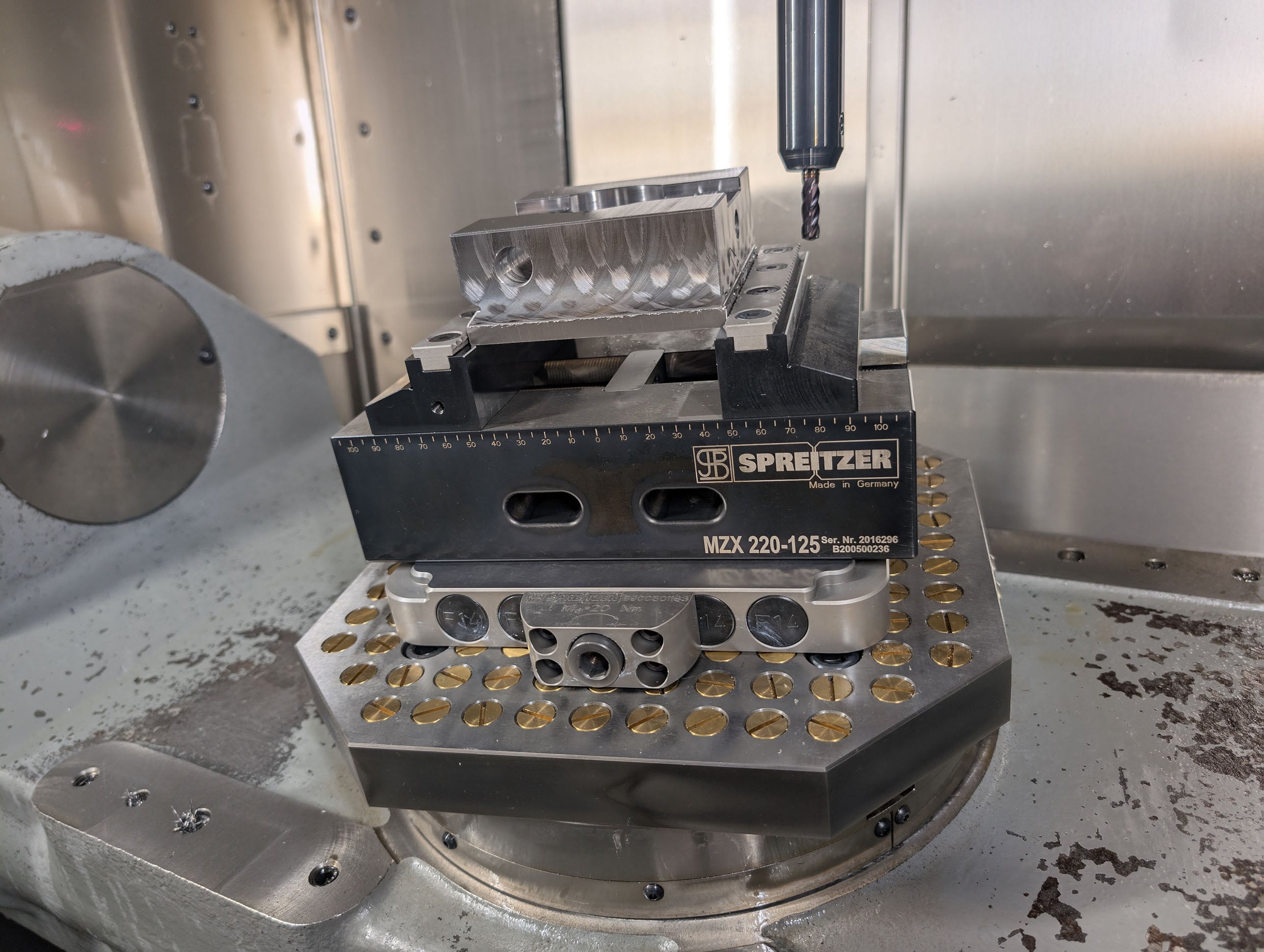

Spreitzer GmbH & Co. KG, a renowned global supplier of mechanical, pneumatic, hydraulic, and electromechanical centric vises, has launched its new mechanical centric vise, the MZX. With this new introduction, Spreitzer continues to innovate and redefine the standards of workpiece clamping in manufacturing. Building on the success of the MZS series, which debuted in 1983, the MZX promises to meet the most demanding requirements of modern manufacturing environments and zero-point clamping systems.

The MZX vise is engineered to deliver process-reliable clamping with a remarkable repeat accuracy of 0.01 mm. It incorporates a powerful spindle, a zero-backlash spindle bearing, and stable jaw guidance. This combination ensures that the vise provides consistent and uniform clamping force for enhanced precision in machining processes. The open construction of the MZX not only optimizes chip evacuation but also guarantees smooth operation during machining tasks, preventing any disruptions that could affect the quality of the workpiece.

The vise is designed to accommodate both raw and finished part clamping, making it versatile across various stages of manufacturing. It comes with interchangeable jaw variants that include integrated grip inserts, clamping rails, and grip jaws. Additionally, the system is compatible with pre-stamping systems from LANG, enhancing its adaptability for diverse manufacturing setups.

The MZX is available in a wide range of sizes and is prepared for integration with zero-point clamping systems with grid dimensions of 52 × 52 mm or 96 × 96 mm. This ensures maximum compatibility with other clamping systems, making it a highly flexible solution that can easily be incorporated into different production environments. Whether used in small workshops or large-scale automated factories, the MZX’s adaptable design is a key feature that sets it apart from other vises on the market.

In addition to the MZX, Spreitzer has introduced the MDX, a sister model designed for double efficiency. The MDX is a mechanical double centric vise that allows for the simultaneous clamping of two workpieces against a fixed stop. This feature is particularly useful in automated production lines and palletizing systems, where high efficiency and repeatability are essential.

The MDX’s unique spindle design can securely clamp workpieces with length variations up to 2 mm, providing the flexibility needed for high-volume production and serial manufacturing. Like the MZX, the MDX uses interchangeable jaws, further enhancing its flexibility for a variety of clamping tasks.

Both the MZX and MDX vises are designed to be compatible with modern automation systems and zero-point clamping setups. For applications that require automated processes, Spreitzer offers customized gripper grooves, enabling easy automated vise exchange. The vises are also compatible with a broad range of interface patterns and mounting systems, including LANG, SCHUNK, STARK, and ZeroClamp, further emphasizing their system openness and versatility.

With the introduction of the MZX and MDX vises, Spreitzer has once again solidified its position as a leader in centric vise technology. The combination of mechanical robustness, versatility, and precision makes the MZX and MDX the ideal choice for modern, automated production environments. Whether used in small or large-scale manufacturing, these vises offer enhanced performance and reliability, making them a top choice for industries that demand the highest standards in clamping technology.