SMW Autoblok Revolutionizes Clamping Systems with Automated Jaw Changes!

By Ashutosh Arora

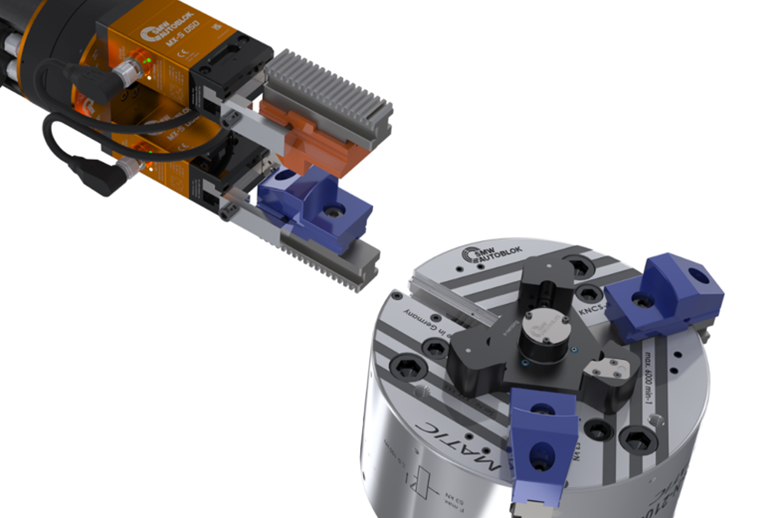

SMW Autoblok, a leading provider of workholding solutions, has introduced the KNCS-matic system, an advanced clamping solution designed to reduce setup times and improve automation in machining processes significantly. The KNCS-matic system enables automatic quick jaw changes for power chucks, integrating seamlessly with industrial robots to streamline and enhance the manufacturing process.

The KNCS-matic is part of SMW Autoblok’s KNCS power chuck family and introduces a new level of efficiency and precision in machining operations. By utilizing a conventional industrial robot, the system allows for the automatic change of jaws. The robot employs a release pin to detach the base jaws, replaces them with new ones, and secures them in place with the pin. This level of automation ensures faster setup times, reducing downtime between production runs and making it ideal for environments with a high mix of components.

One of the standout features of the KNCS-matic system is its ability to maintain self-centering and repeat accuracy despite the quick jaw changes. This ensures that operators can work economically with increasing variations in component specifications without sacrificing precision or production quality. The automation of jaw changes reduces the need for manual interventions, which can be time-consuming and prone to errors.

The KNCS-matic chuck is available in six different sizes, offering a clamping force range of 100-250 kN, depending on the size. This flexibility allows the chuck to be used across a wide range of machining operations. The chuck’s jaws are not only adjustable but can also be displaced or turned, with each jaw offering a range of movement between 7-10 mm. This feature makes it adaptable to different workpiece sizes and machining requirements, further increasing its versatility.

Moreover, the KNCS-matic chuck has a large passage range of 52-165 mm, a feature typical of the KNCS series, allowing for larger workpieces to be processed efficiently. With speeds ranging from 1,700 to 6,000 rpm, the chuck ensures high-speed machining while maintaining consistently high levels of precision. The Proofline seal technology further enhances the chuck’s durability and low maintenance requirements, making it a reliable choice for industries seeking long-term performance.

The integration of automated quick jaw changes with industrial robots and SMW Electronics elevates the KNCS-matic system, positioning it as a key player in smart manufacturing. The system’s ability to seamlessly interact with automated clamping devices brings workpiece processing one step closer to the digital factory. Additionally, MX-S mechatronic grippers from SMW Autoblok’s MOTIACT product range can be used for jaw replacement, ensuring smoother automation transitions. The F100 inductive coupling system provides contactless transmission of energy and signals between the robot arm and gripper, further enhancing the system’s ease of use and efficiency.

With the KNCS-matic system, SMW Autoblok not only enhances productivity through automated clamping and jaw changing but also contributes to the ongoing evolution of digital factories. By reducing manual intervention and optimizing setup times, manufacturers can achieve faster production cycles, lower operational costs, and ultimately, a more efficient and scalable manufacturing process.

Incorporating the KNCS-matic system into existing operations positions companies to take full advantage of automated solutions and high-precision machining, ensuring they stay competitive in the ever-evolving manufacturing landscape.