Siemens Introduces Machinum CNC Digitalization Portfolio to Accelerate Manufacturing Efficiency!

By Ashutosh Arora

At Eastec 2025, Siemens unveiled its Machinum CNC digitalization software portfolio, a comprehensive solution designed to streamline digital transformation within the manufacturing sector. The portfolio aims to enhance shopfloor performance, improve productivity, and optimize machine tool operations through seamless software integration. By leveraging Siemens Xcelerator, the technology facilitates faster, more efficient, and scalable digital transformation across both manufacturing and design processes.

The Machinum portfolio is designed to integrate effortlessly into existing manufacturing environments, including those utilizing Sinumerik-controlled CNC machines. Unlike traditional systems, this portfolio is not limited to Siemens machinery, making it versatile and adaptable to a wide range of machine tool setups. This level of flexibility is key to supporting the diverse needs of manufacturers, ensuring that the digitalization process is smooth and accessible for companies of all sizes.

With the rise of energy efficiency and sustainability requirements in manufacturing, the Machinum portfolio helps businesses meet these growing demands by improving high-quality product manufacturing. This integration leads to a more sustainable and efficient operation, reducing waste and energy consumption while boosting overall production capabilities.

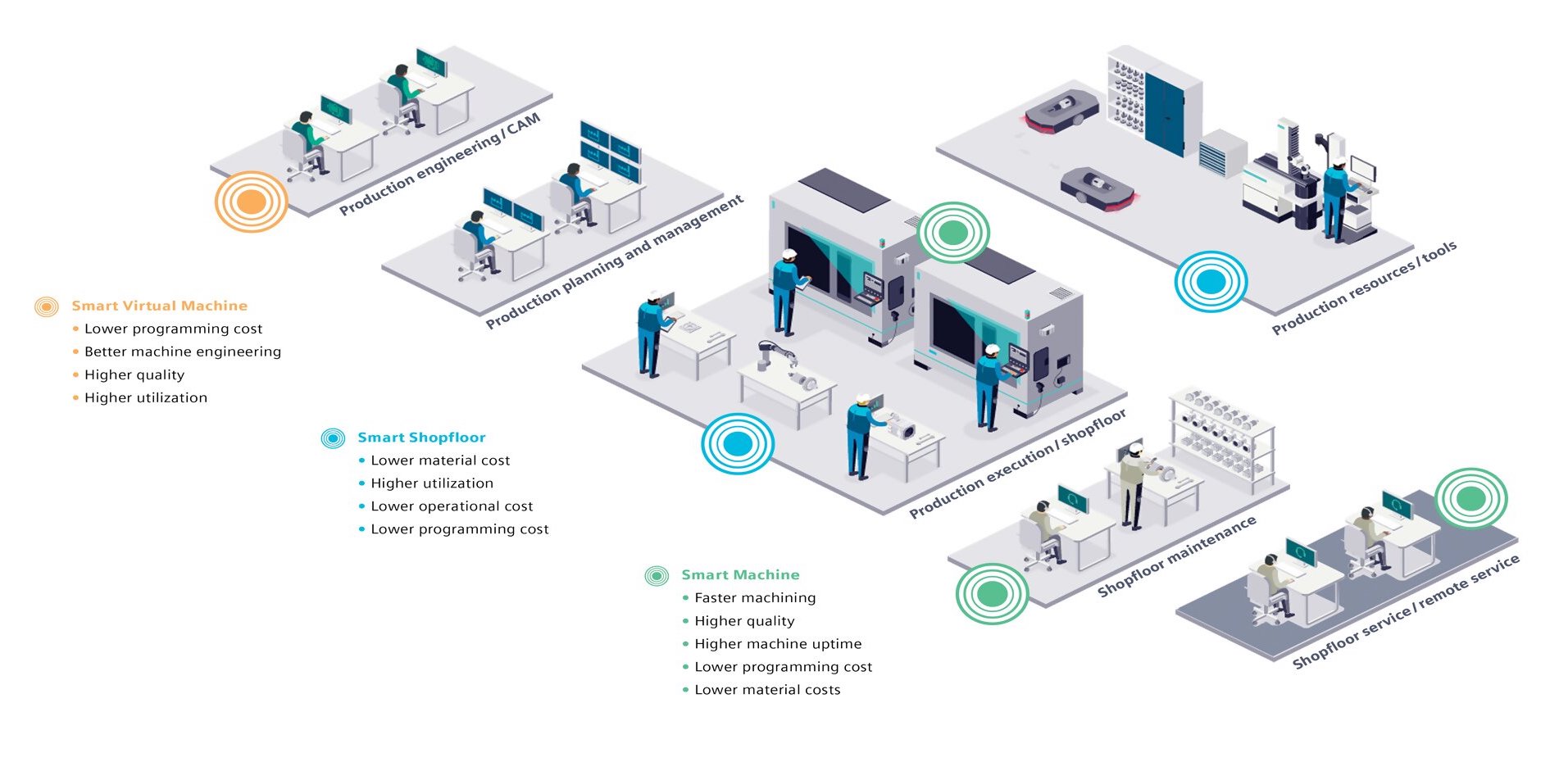

The Machinum portfolio is structured around three core pillars, each targeting a specific aspect of the manufacturing process to improve efficiency and performance:

- Smart Machine: Focuses on optimizing machine uptime and lowering programming and material costs. By utilizing machine data for real-time, in-process quality control, this pillar allows for faster machining and better overall productivity. It helps users achieve higher quality and reduced downtime, ensuring that machines operate at peak efficiency.

- Smart Shopfloor: Designed to reduce material, operational, and programming costs, while increasing utilization. By improving the preparation and pre-production resource management stages, this pillar helps businesses optimize shopfloor resources, ultimately increasing throughput and reducing waste.

- Smart Virtual Machine: Integrates digital twin technology to simulate virtual machining processes, which accelerates the development and testing of new parts. This capability leads to lower programming costs, improved machine engineering, and better utilization. By enabling closed-loop engineering, the Smart Virtual Machine pillar supports a faster run-in of new parts and reduces costly downtime.

One of the standout features of the Machinum portfolio is the inclusion of Adaptive Control and Monitoring (ACM). This technology enables real-time adjustments to machining processes, reducing machining times by up to 15% and extending the life of cutting tools. By monitoring and adapting to changes in the machining environment, ACM ensures that operations remain optimized for performance, reducing the need for manual intervention and improving overall process reliability.

Siemens’ Machinum CNC digitalization software portfolio is not only designed to improve immediate machine performance but also to enhance the speed, agility, and endurance of operations. Through the integration of advanced digital technologies such as digital twins, the portfolio accelerates innovation and provides manufacturers with the tools they need to stay competitive in a rapidly evolving industry.

In summary, Siemens Machinum CNC digitalization software portfolio is a robust, scalable solution designed to transform manufacturing environments. By integrating advanced automation, digital twin technology, and real-time monitoring, this portfolio enables manufacturers to enhance efficiency, reduce costs, and improve product quality, paving the way for a smarter, more sustainable manufacturing future.