Severance Tube End Finishing Tools Deliver Chatter-Free Performance and Single-Operation Efficiency!

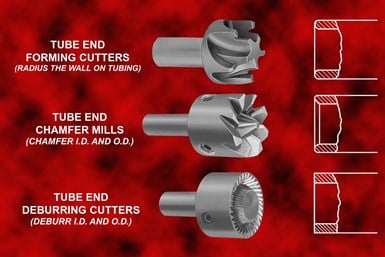

Severance Tool Industries has developed a specialized lineup of tube end finishing rotary tools designed to deburr, form, and chamfer tubing ends with high precision and repeatability. These tools are engineered to finish both the inside diameter (ID) and outside diameter (OD) of a tube in a single operation, helping manufacturers reduce cycle times, simplify setups, and achieve consistent edge quality.

A key advantage of Severance’s tube end finishing tools is their ability to accommodate varying wall thicknesses on the same tube diameter. Many of the tools feature an adjustable, two-piece construction that allows the outside member to be set precisely for the required OD edge break or chamfer. This flexibility is especially valuable in production environments where tubing dimensions vary slightly, but consistent finishing quality is still required.

For applications where vibration and surface inconsistency are common challenges, select tools in the range incorporate chatter-free tooth geometry. This design alternates tooth-cutting angles to disrupt resonant vibration between the tool and workpiece. By eliminating chatter, the tools produce smoother finishes, improve dimensional consistency, and reduce the risk of tool wear or part damage during operation.

Another distinguishing feature is Severance’s Grayhone finish, which delivers cutting edges that are ready for use immediately. Unlike tools that require a break-in period to achieve optimal cutting performance, Grayhone-finished tools can be put into production right away, helping shops maintain throughput and reduce setup delays.

The product range includes a full selection of tube deburring tools manufactured in either high-speed steel or carbide. These tools are designed for light-duty applications where the goal is to break sharp edges cleanly and efficiently. They simultaneously produce a 30-degree inside chamfer and a 45-degree outside deburr, using a shearing cutting action that promotes fast cutting while preventing chip loading. Operating at speeds between 50 and 200 rpm, the deburring tools can be reground multiple times, providing long service life and lower overall tooling costs. Standard sizes cover tubing from 1/8-inch OD (1/16-inch ID) up to 2-1/4-inch OD (2-inch ID), with multiple shank options available to suit different machines.

For more demanding applications, Severance also offers tube end chamfer mills designed for heavier-duty cutting. These tools use the same shearing action and adjustable outside ring but incorporate chatter-free angle geometry optimized for machining precise and smooth chamfers. They are capable of producing accurate 45-degree OD and 30-degree ID chamfers, making them well suited for applications where tubes must fit easily into mating components or assemblies. Chamfer mills are available for pipe and tubing sizes ranging from 3/16 inch to 2-1/2 inches OD.

Overall, Severance’s tube end finishing tools are designed to improve productivity and finish quality by combining single-operation capability, vibration control, and adjustability. By addressing common issues such as chatter, chip loading, and dimensional variation, the lineup provides a reliable solution for manufacturers seeking efficient and repeatable tube end finishing across a wide range of applications.