Select Machining Technologies Unveils Enhanced Gen 6 ZVH Series for Precision and Efficiency!

By Ashutosh Arora

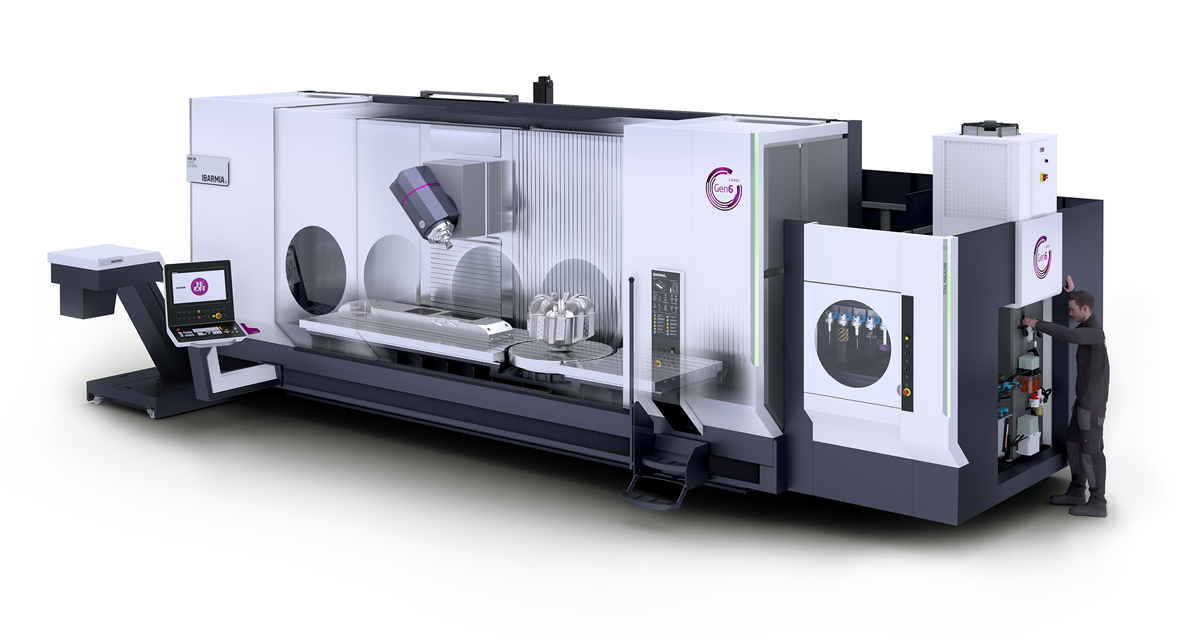

Select Machining Technologies introduces the Gen 6 ZVH series of four- and five-axis traveling-column machining centers from Ibarmia, offering manufacturers cutting-edge capabilities designed for precision, efficiency, and the ability to handle large, complex workpieces. The latest updates to the ZVH series are specifically tailored to meet the increasing demands of precision machining, particularly in industries such as aerospace, automotive, and defense, where accuracy and speed are paramount.

The most significant upgrade to the Gen 6 ZVH series is a 20% increase in the work envelope for five-axis machining. This improvement was achieved by reducing the distance between the spindle nose and the swiveling axis, bringing the spindle nose 2.76 inches closer to the workpiece compared to the previous Z series models. The horizontal spindle nose can now be lowered to just 9.8 inches above the table, allowing for better accessibility and more effective machining on large, heavy parts.

The Ibarmia ZVH series is available in two configurations: the ZVH Extreme four-axis and five-axis models, as well as the ZVH Multiprocess, which integrates both five-axis milling and turning capabilities into a single machine. This flexibility makes the ZVH series highly versatile, allowing manufacturers to handle a wide range of applications on one machine. The X-axis travel ranges from 63″ to 472″, Y-axis travel from 24″ to 43.3″, and Z-axis travel from 31.5″ to 51.2″, ensuring that the ZVH can accommodate large workpieces while maintaining the precision necessary for complex machining tasks.

Another key feature of the Gen 6 ZVH series is the inclusion of a swiveling B-axis with a swing of up to ±115 degrees. This enhanced flexibility allows for greater precision in machining angles, while integrated C-axis rotary tables are available with swing diameters from 35.4″ to 86.6″, further expanding the range of operations the ZVH series can perform.

For improved performance and capacity, the Gen 6 ZVH machines are equipped with spindle options that include 57.7 hp or 61.7 hp at 20,000 rpm, or a more powerful 112.6 hp at 12,000 rpm. These spindle options allow the machine to tackle a wide variety of challenging applications with ease, ensuring both efficiency and high-quality finishes.

One of the standout improvements in the Gen 6 ZVH series is the redesign of the automatic tool changer (ATC). In this iteration, the tool magazine has been moved from behind the traveling column to the side of the machining area. This adjustment enables operators to exchange tools without interrupting the machining process, as the tool change occurs outside the active working area. As a result, the new configuration not only speeds up operations but also improves safety and minimizes downtime. Additionally, the moving column design is now stiffer and more dynamic, resulting in a 30% improvement in acceleration, which contributes to faster machining cycles and better overall performance.

To further accommodate a wide range of tools and machining needs, the Gen 6 ZVH offers a flexible tool magazine with options for 60-120 tools, available in various spindle tapers including SK 40, BT 40, SK 50, BT 50, HSK 63, and HSK 100. The machine is compatible with leading CNC control systems, including FANUC, Heidenhain, and Siemens, ensuring seamless integration into existing operations.

Additionally, the width of the machining center has been reduced by nearly 20 inches, making the ZVH series more compact and efficient in terms of floor space utilization. This reduction in size also contributes to lower shipping costs, making the machines more economical to transport.

The Gen 6 ZVH series is an ideal solution for manufacturers looking to enhance their capabilities in high-precision, high-performance machining. With its improved dynamics, increased work envelope, enhanced automation, and versatile configurations, the ZVH series continues Ibarmia’s legacy of producing top-tier machining centers designed for today’s demanding manufacturing environments.